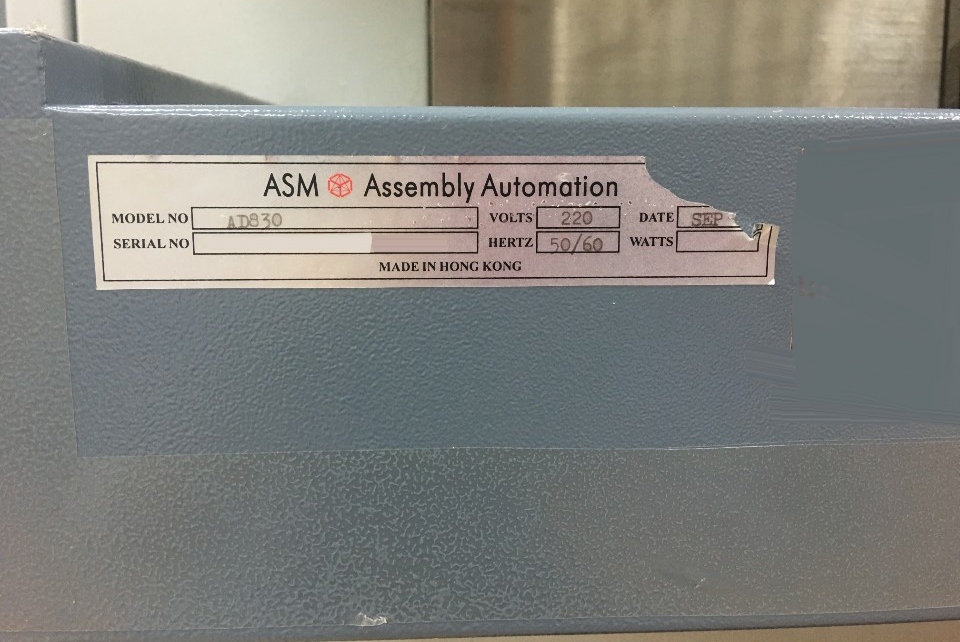

Used ASM AD 830 #9285179 for sale

URL successfully copied!

Tap to zoom

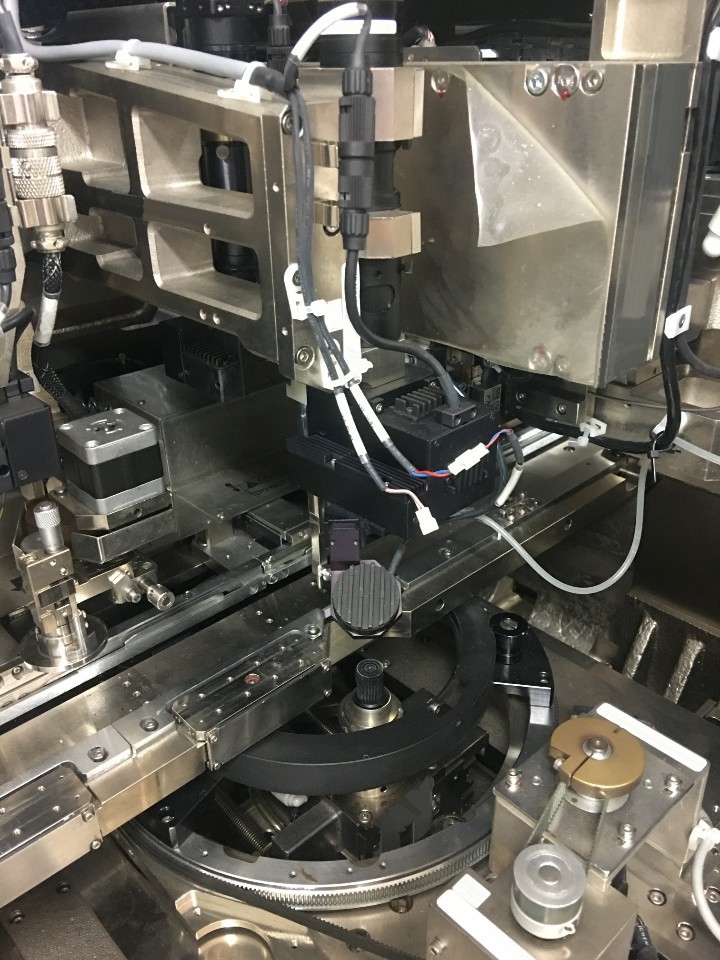

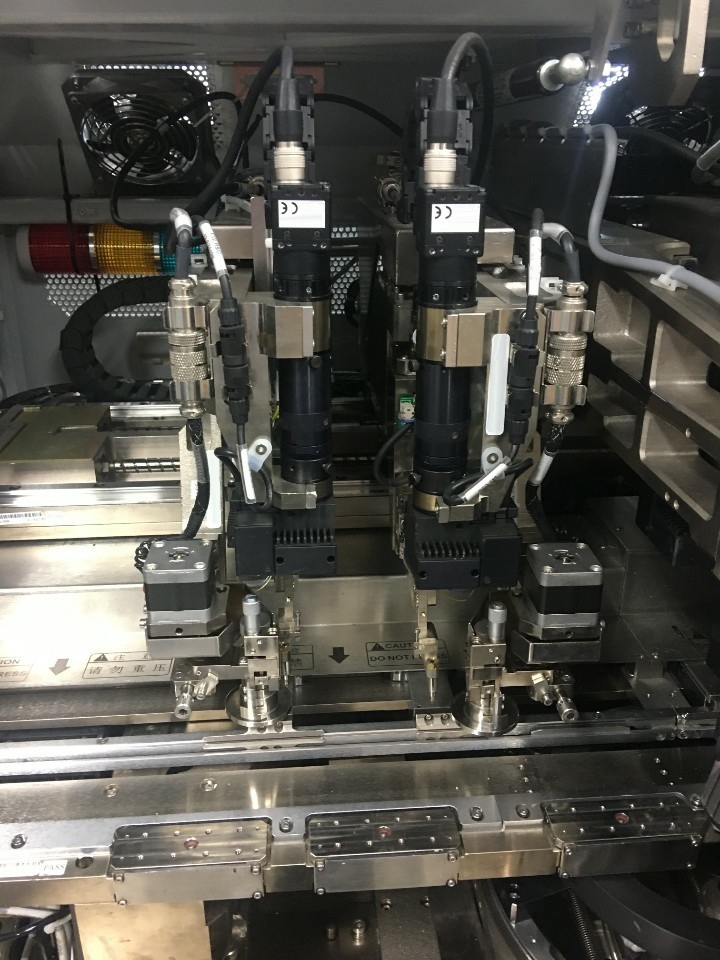

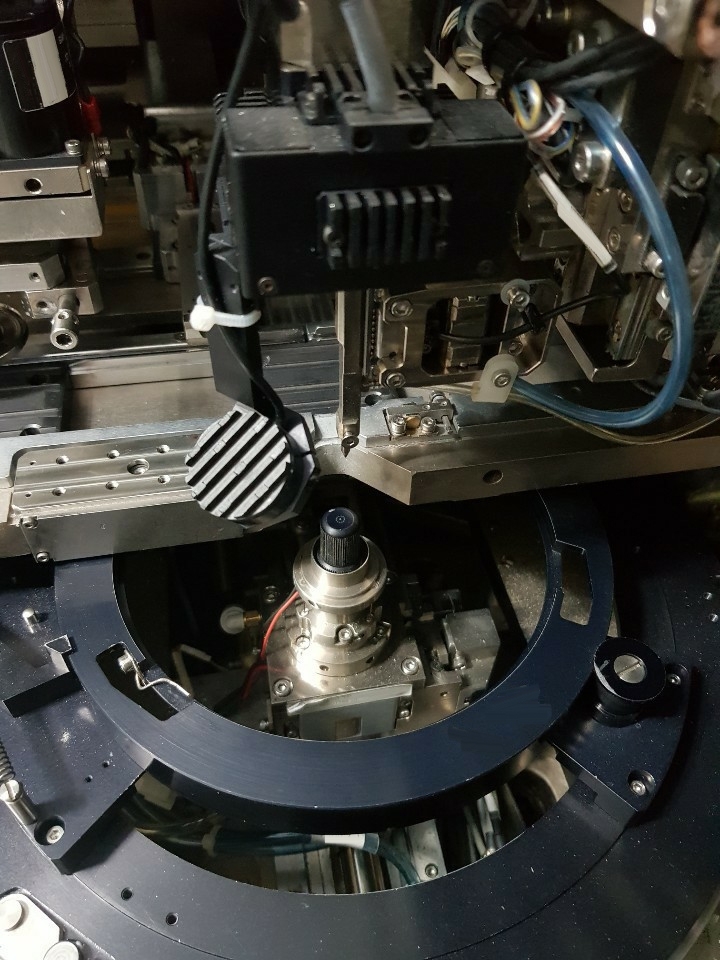

ASM AD 830 is a robust and reliable lead-free hot bar die bonder with a high speed lead-free bonding process. Its self-threading design provides an accurate and reliable process with a very low thermal shock to the wire and die. Its integrated camera equipment provides a higher resolution and the highest accuracy. ASM AD830 attaches die at 30W power levels, making it one of the fastest die attachers available. AD 830 features a very precise and fast displacement mechanism that moves the die accurately over a very wide range of positi ons. Its advanced control allows precise adjustment of the starting point and position of each pass. This ensures fast and accurate placement of the die and wires. The system features a faster, higher performance bonding process, with a reduced risk of delays due to overstretching, misalignment, or partial contact of wires. AD830 includes a suite of configurable software features designed to maximize efficiency and accuracy of the bonding process. Its smartphone-like user-friendly graphical interface allows operators to easily monitor process settings, adjust parameters, and check die and wire positions. ASM AD 830 also includes an easy-to-use maintenance program that schedules, monitors, and evaluates periodic maintenance tasks. The unit's light beam monitoring ensures precise alignment of the die and wire connections in order to enable fast and accurate placement. The built-in diagnostics machine verifies the quality of the die bond during process and troubleshoot the operation if necessary. Additionally, the tool is equipped with a temperature control unit to keep die and substrate temperatures within a safe range. This helps prevent melting of solder, a potential issue when using high power during die attach process. Overall, ASM AD830 offers a reliable, accurate, and fast die attacher that enables high-speed lead-free bonding processes with minimal thermal shock to the die and wires. Its user-friendly graphical interface, light beam monitoring, and built-in diagnostics add convenience and accuracy to the asset. With its built-in temperature control and maintenance program, users can rest assured that their die attach process is safe and accurate.

There are no reviews yet