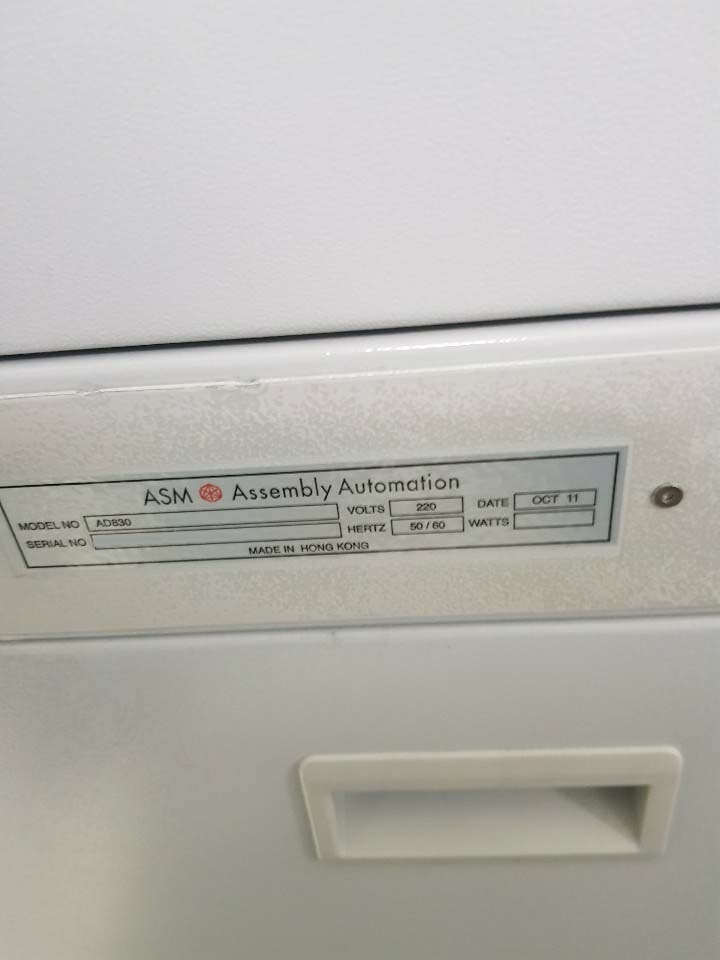

Used ASM AD 830 #9291861 for sale

URL successfully copied!

Tap to zoom

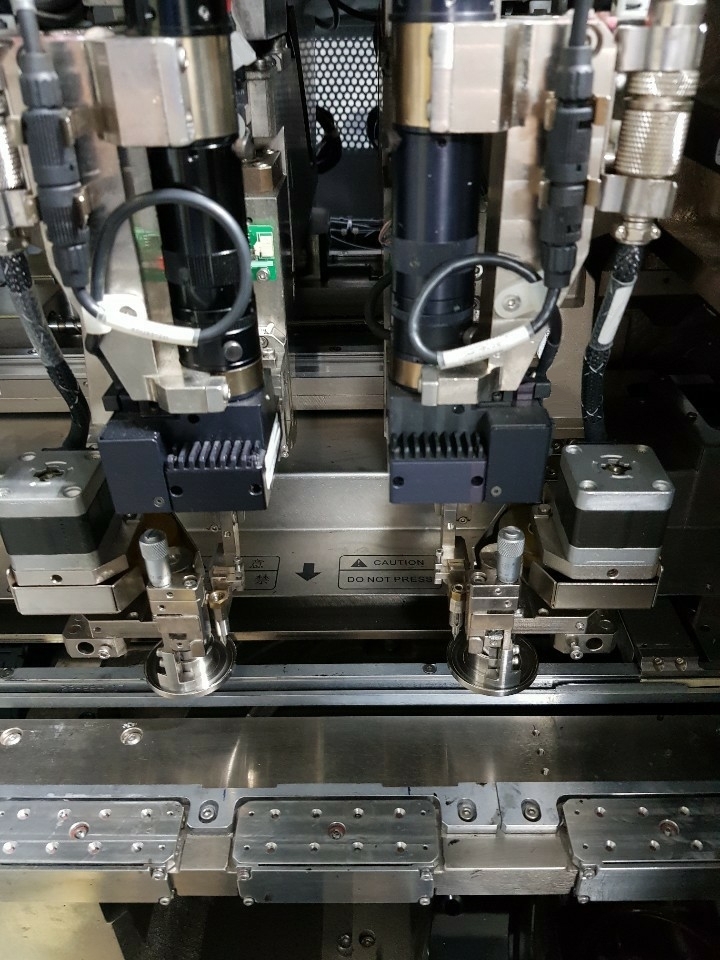

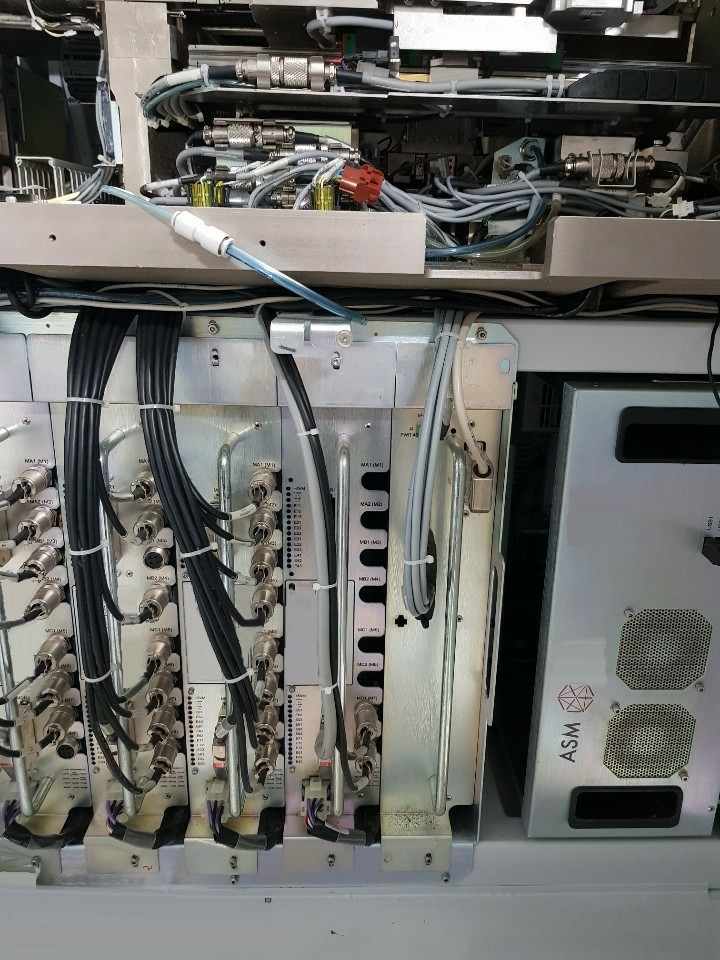

ASM AD 830 Automatic Die Attacher is a high-speed, reliable and user-friendly solution for mass die attaching operations. It is suitable for a variety of die sizes and shapes, and provides a reliable, repeatable and automated attaching process. ASM AD830 is designed for both manual and automatic operation and is capable of working to very tight attaching tolerances. AD 830 utilizes a pneumatically driven feed mechanism to ensure a consistent delivery of die material. This feed mechanism can be set to provide a continuous or delayed release of the die material at a rate that is adjustable according to the size and shape of the die being attached. The die is then placed onto a board, where a heated element contacts the die and bonds it to the board. A number of sensors then detect the die's presence and verify its correct positioning. In terms of safety, AD830 features durable, vibration dampening components that guard against any vibration-related failures. Additionally, it is designed with built-in guard rails which help protect the user against any accidental contact with the die during the attaching process. ASM AD 830 further features an LED interface which allows users to easily monitor and adjust the attaching process, as well as select from a number of pre-programmed attaching options. Furthermore, it includes an automated self-test feature that checks the mechanical and software parameters of the unit on a regular basis to ensure it is operating correctly. In terms of operation, ASM AD830 is capable of attaching dies of a variety of shapes and sizes at speeds up to 15,000 attachments per hour. It can also attach two dies simultaneously, and can mount up to 500 dies per board. Additionally, the unit's compact size ensures that it can be easily and conveniently placed in-line with existing production lines. To summarize, AD 830 Automatic Die Attacher is an advanced and highly reliable automation solution designed for high-speed die attaching operations. Thanks to its durable components, friendly user interface and automated testing features, it is a great choice for any die attaching application.

There are no reviews yet