Used ASM AD 830 #9312262 for sale

URL successfully copied!

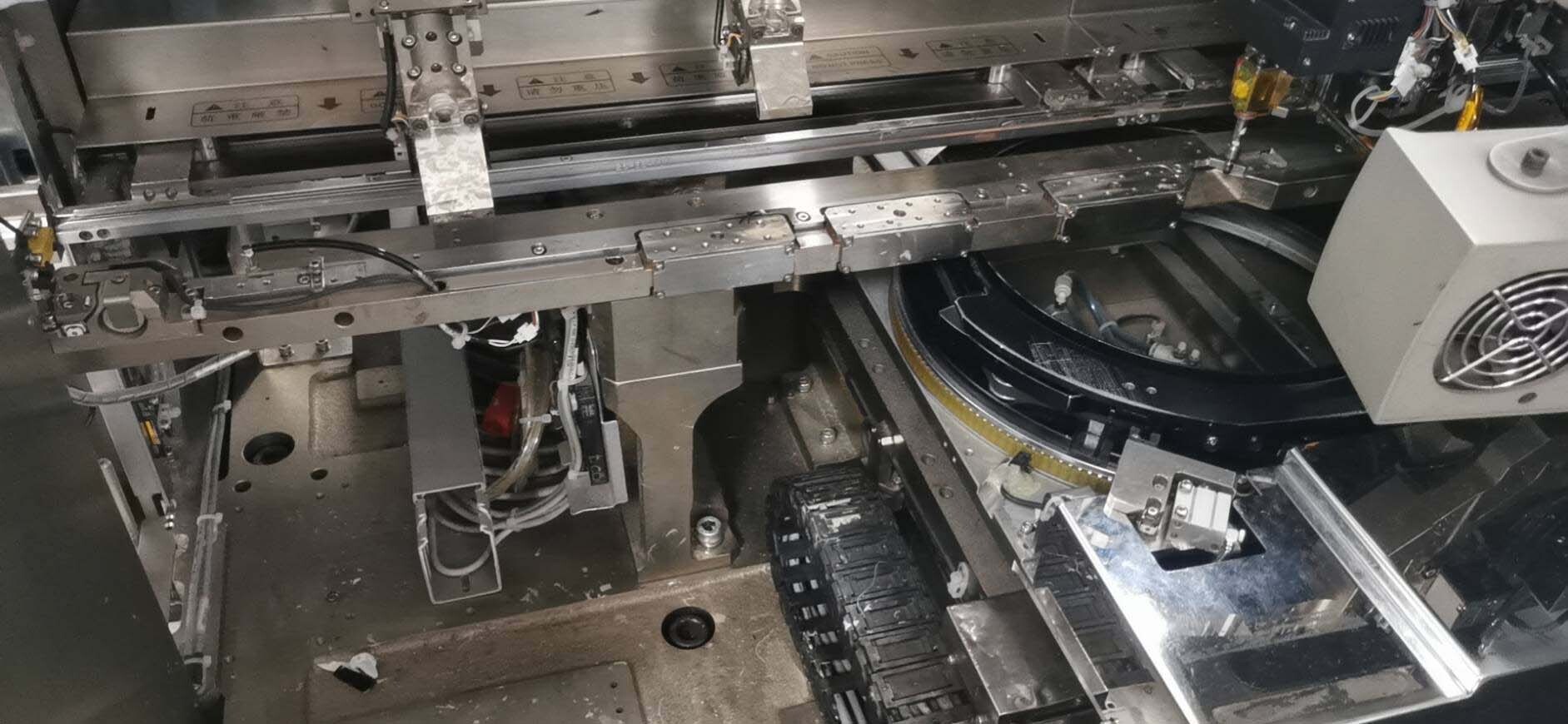

Tap to zoom

ASM AD 830 is an automatic die attach equipment that is designed to increase throughput and reliability on the production floor. It is a die-placement tool that allows for the accurate and repeatable placement of a wide range of die sizes. ASM AD830 significantly reduces the time required for chip-mounting and offers improved yields, while eliminating the potential for user error and physical strain associated with manual die placement. The system is composed of two main components; the vision unit, responsible for guiding the placement of the component, and the applicator head, which moves the die into place. The vision machine uses a combination of image processing and sensors to create an accurate map of the substrate, helping to reduce the die placement time. A pneumatic control tool is used to apply a load onto the die, ensuring the accuracy of the bond. AD 830 is a robust, high-performance asset designed for integration into existing SMT production lines. It is highly flexible and can be configured for a variety of different applications. Furthermore, its modular design allows for fast, easy, and cost-effective customization to meet specific production requirements. AD830 can also be used with a range of configurable components and an integrated interface for data exchange between systems. This ensures that the model is easy to use, and provides precise results with minimal operator intervention and training. The entire machine is controlled by a user-friendly software application that can be customized to manage complex production process. It can be easily integrated with automated assembly and testing systems as well as other enterprise data systems. ASM ensures that all relevant process parameters are logged on a central database at the company-floor level for easy tracking. All in all, ASM AD 830 is a reliable and accurate die-mounting equipment that offers improved yields and throughput. Its modular design and intuitive interface make it easy to integrate into existing production lines and its integrated software provides comprehensive data management capabilities. It is an ideal tool for attracting high-precision results in fast-paced production environments.

There are no reviews yet