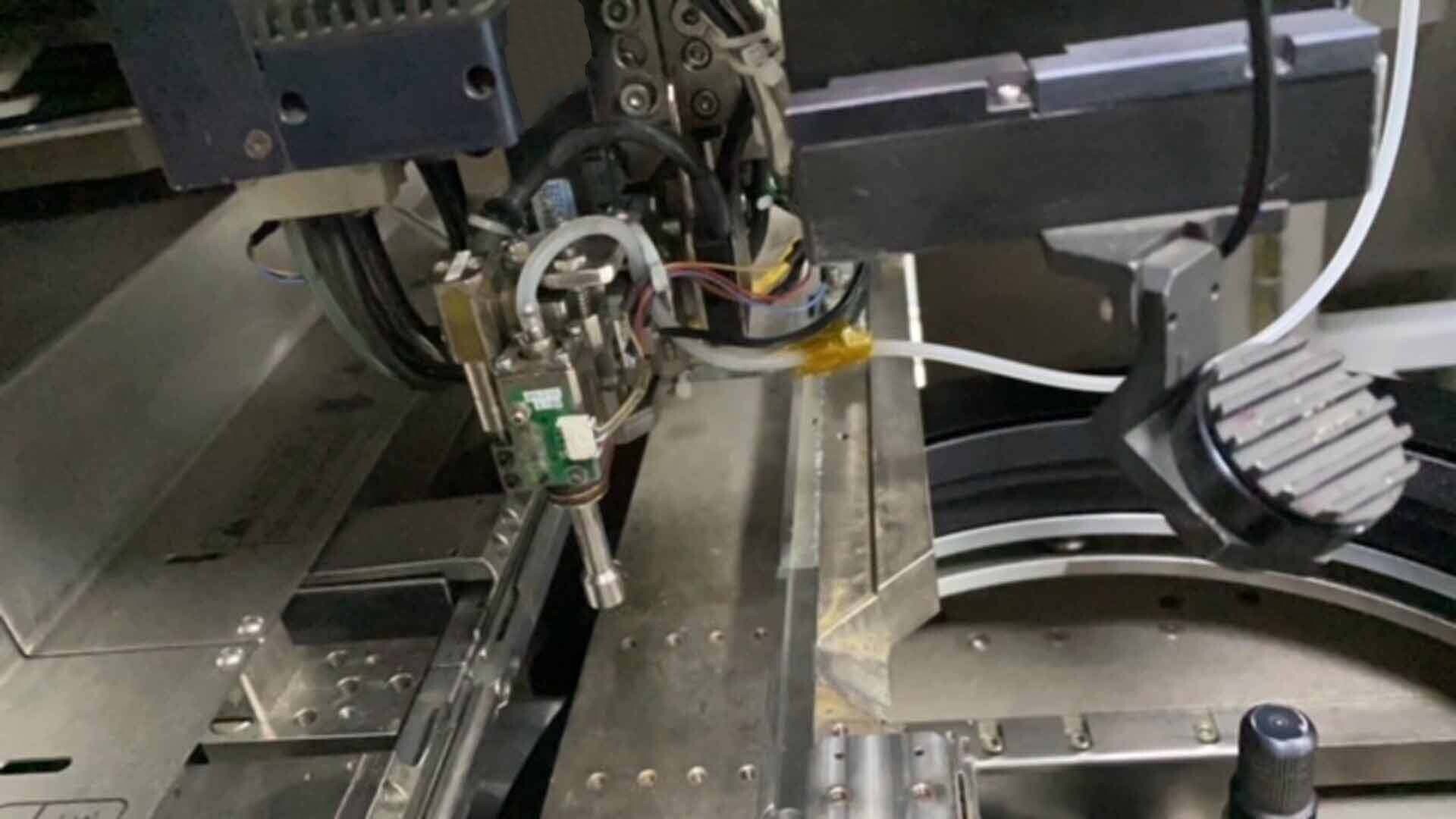

Used ASM AD 830 #9352428 for sale

URL successfully copied!

Tap to zoom

ASM AD 830 is an automatic die attacher designed for inserting dies and forming a reliable electrical connection between a board-mounted component and its printed circuit board (PCB). Assembled with a pneumatic toggle-arm system, ASM AD830 provides secure die attachment and maintains high accuracy in the process. AD 830 is a versatile machine capable of attaching a wide variety of different die sizes ranging from 0402 to 1008. It features an extensible configuration and a simple user interface, allowing manufacturers to customize the machine to fit their specific needs. The automated die attachment process consists of four primary steps: unscrambling, orienting, placing, and reflowing. AD830 is capable of simultaneous unscrambling, orienting, and placing of die, significantly reducing the total cycle time. Once placed, the die is reflowed in order to form a reliable connection with the PCB. The versatile nature of ASM AD 830 means that it can handle various types of dies. Additionally, it can accommodate a wide range of reflow processes. ASM AD830 employs a visioning system to ensure that proper placement of the die is achieved. The system uses a camera to capture images of the die placement and adjusts the placement of the die accordingly. This ensures accuracy and accuracy in die placement. AD 830 features a full range of load and unload capability with a maximum range of 700mm. It also features multiple functions for accommodating components, enabling quick and accurate insertion. With its adjustable air pressure and stroke, AD830 can be adjusted for optimal settings for maximum productivity. For additional safety, ASM AD 830 is equipped with an emergency stop button and a safety release switch to protect against unplanned startup and potential hazards. Furthermore, maintenance and troubleshooting are made easy with visual diagnostic status codes and alarms. In terms of reliability, ASM AD830 has a long useful life with an average MTBF rating of more than 50,000 cycles. It can also operate at speeds of up to 100 cycles per minute and is highly efficient, reducing operating costs. AD 830 is an ideal choice for manufacturers as it provides reliable die attachment and highly efficient output.

There are no reviews yet