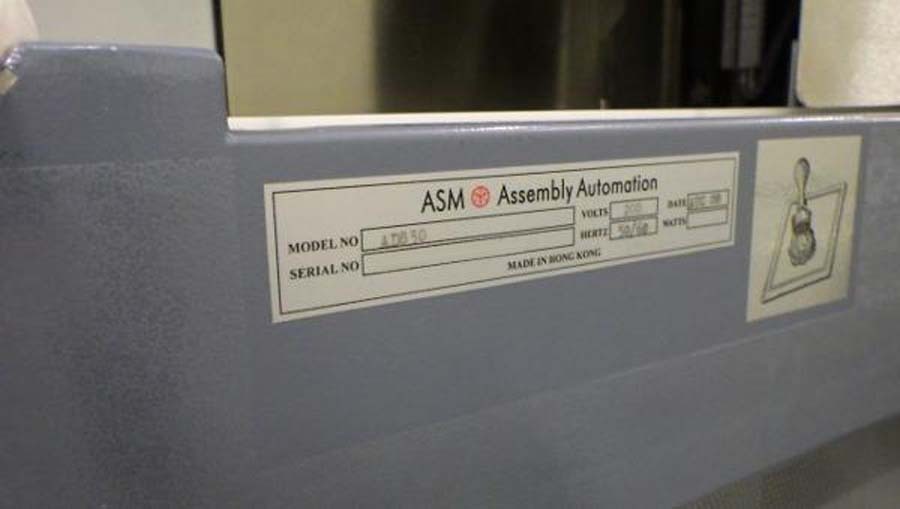

Used ASM AD 830 #9395324 for sale

URL successfully copied!

Tap to zoom

ASM AD 830 is a fully automated and proven solution for die attachement in electronics assembly. This equipment simplifies the process of attaching DIP or SMD chips to printed circuit boards with its agile vacuum press system. ASM AD830 is designed to achieve reliable die attachment in SOP, SOJ, PLCC and leadless chip carrier packages. AD 830 operates with precision and can be adjusted easily for fixture changeover. It features a smooth, twin head contact system for consistent, high quality results. The machine is equipped with a 150W hot air device and temperature control for consistent and repeatable temperature uniformity when attaching the die to the circuit board. The control panel is user-friendly, and the machine can be integrated into existing production lines easily and quickly. The vacuum press used by AD830 is designed for high speed and accuracy. It can press an area of 0.1mm to 10mm depending on the chip type and size. It also offers three-point pressing capabilities, giving it great versatility and accommodating different die sizes. The vacuum press ensures that the die is pressed and secured in a single pass, with both top and bottom contacts being pressed evenly at the same time. ASM AD 830 includes a feeder for accurate chip picking. It is capable of picking and placing chips quickly and accurately, while its advanced vision system ensures accurate pick-up and placement. The machine is also equipped with a precise laser rating sensor which calibrates the feeder prior to die attachment. ASM AD830 is designed for production line automation and is capable of handling up to 16,000 products an hour. Its fully automated, one-minute fixture changeover feature allows it to quickly adjust for a variety of die sizes, while its automatic pass detection function ensures a zero-defect rate. This machine is reliable and cost-effective, and can be an invaluable asset to any electronic assembly line.

There are no reviews yet