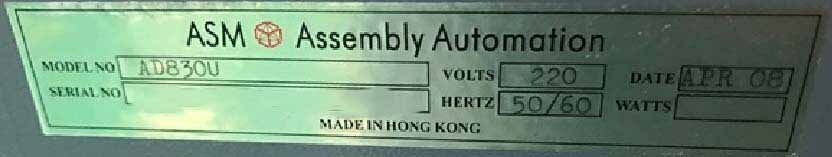

Used ASM AD 830U #9177552 for sale

URL successfully copied!

Tap to zoom

ASM AD 830U is an automatic die attacher that is designed to provide efficient die attaching to a variety of substrates. It can be configured to attach up to 3 die components simultaneously and is especially suitable for applications requiring multiple mounting points, such as automotive safety control systems. ASM AD830U provides a reliable and consistent die bonding process with adjustable speeds ranging from 8 to 32 die attaching points per second. The die bonding process is also highly accurate due to an integrated vision equipment, which ensures that the exact location of the die is determined before attachment. This ensures that there are no misalignment issues when the die is attached. AD 830U also ensures precise die setting through its stage system, which can be adjusted to fit the particular substrate involved in a die attaching job. It can be set to either the static mode or the dynamic mode, depending on the type of application. In the static mode, the stage will move in a fixed pattern, while in the dynamic mode, it will move in a random pattern to minimize high temperature buildup on the die. This helps to prevent thermal damage to the die during the attachment process. AD830U also includes an automatic die cleaning unit, which is designed to remove any contamination from the die before attachment. This helps ensure that there are no poor results during the die attaching process, as it removes foreign particles that could block the contact points. In addition, the machine also features adjustable dispense volume settings, which allows users to set the ideal amount of material for the particular application. Overall, ASM AD 830U is an automated die attaching tool that is designed for use in a wide variety of applications. It provides a reliable and consistent attachment process, along with adjustable settings to suit various substrates and die sizes. The asset also features an integrated vision model and automatic die cleaning equipment, ensuring that the best possible results are achieved each time. In addition, its adjustable dispense volume settings help ensure that the right amount of material is used during the die attaching process, creating a strong bond between the die and substrate.

There are no reviews yet