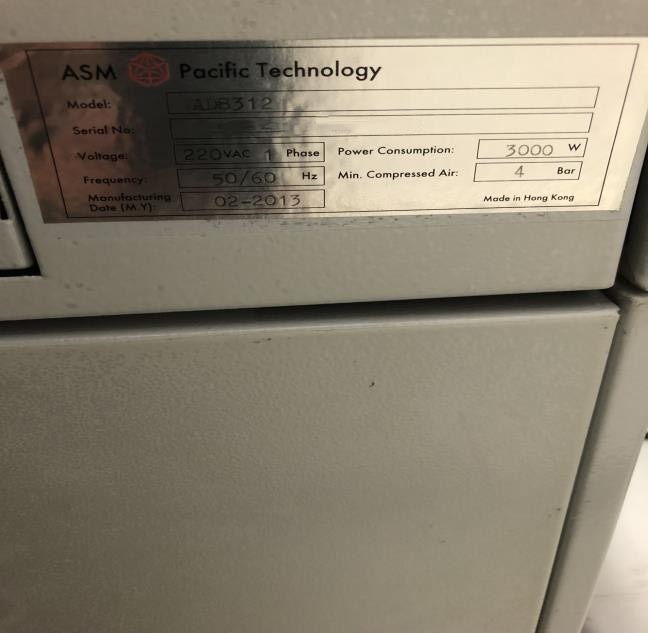

Used ASM AD 8312 #293602225 for sale

URL successfully copied!

Tap to zoom

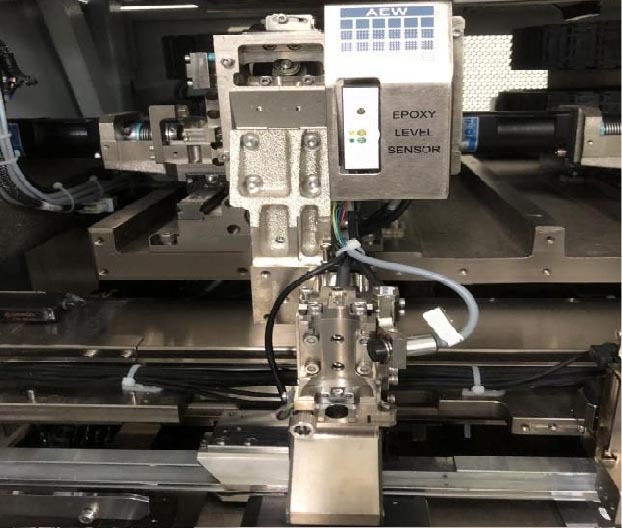

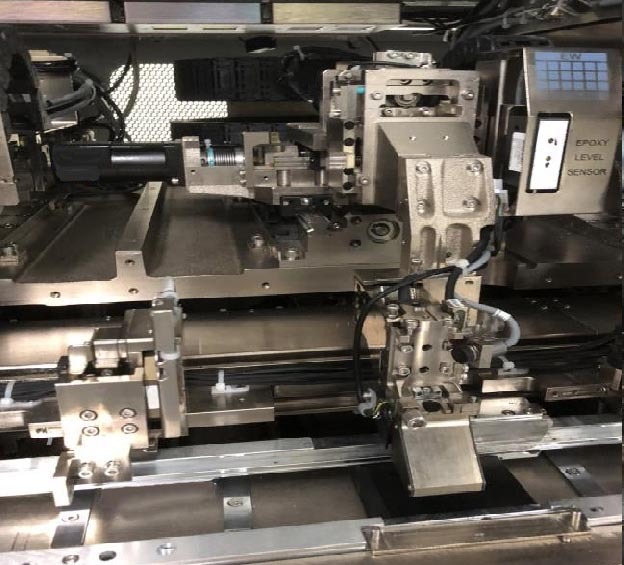

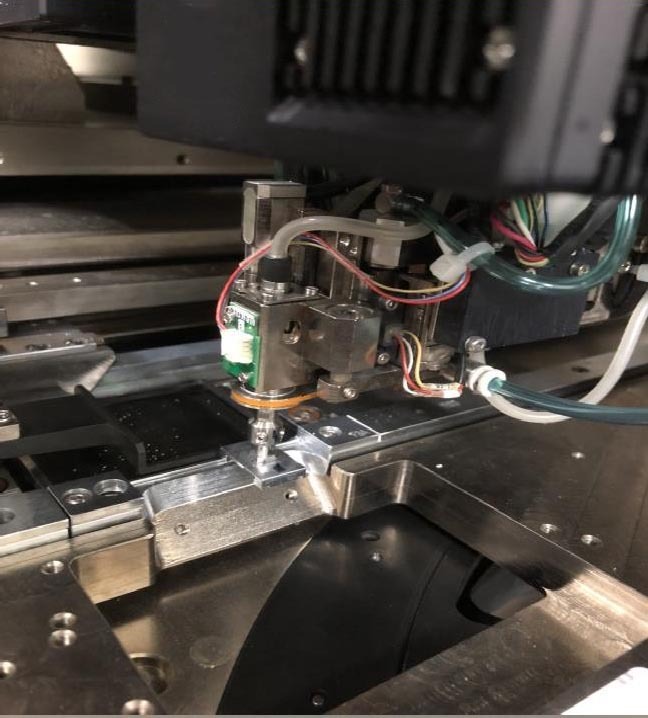

ASM AD 8312 is a die attacher which is used for attaching devices to printed circuit boards. It has a die based on the patented floating die equipment with spring loaded pick and place mechanism. The die features 0.5 μm positional accuracy with a cycle time of 8 ms. The machine is capable of attaching devices up to 75 mm with a placement accuracy of ±0.002 mm. ASM AD8312 die attacher is a vertical placement system consisting of multiple components. The main components are the vertical motion unit, the die, the vision machine, the control tool and the pick-and-place asset. The vertical motion model consists of a magnetic linear encoder, a load cell, a pulley and a belt, and a stepper motor. The encoder is used to measure the displacement of the load cell, while the belt and pulley are used to convert the force applied to the load cell into vertical motion. The stepper motor is used to control the motion of the load cell and the belt, and the load cell is used to sense the force applied. The die is the most important component of the attacher. It uses a floating die equipment, with springs attached to the die which are used to keep the die in place and create an adjustable tension. The die contains 0.5μm positional accuracy, allowing for the precise attachment of parts onto printed circuit boards. The die also features a special coating that increases life expectancy and prevents die wear. The vision system is used to inspect and verify the placement of the device onto the board before and after the attachment. The vision unit consists of a high-resolution CCD camera, image recognition and analysis software, and a lighting machine. The CCD camera allows for the capturing of high-resolution images, and the software is used to analyze the images and verify the placement of the device. The control tool is responsible for controlling all aspects of the placement process. It consists of a main processor and multiple peripheral cards, and is programmed to control the motion of the attacher, the vision asset and the pick-and-place model. Finally, the pick-and-place equipment uses a vacuum to pick up the device and then accurately place it onto the printed circuit board. The system uses two vacuum pumps, one for picking up the device and one for placing it. The unit also includes pressure sensors, which are used to ensure that the device is firmly attached to the board. In conclusion, AD 8312 die attacher is a device used for attaching devices to printed circuit boards. It features 0.5μm positional accuracy, allowing for precise attachment. The attacher includes a vertical motion machine, a die, a vision tool, a control asset and a pick-and-place model. These components make the attacher extremely precise and reliable for attaching devices to printed circuit boards.

There are no reviews yet