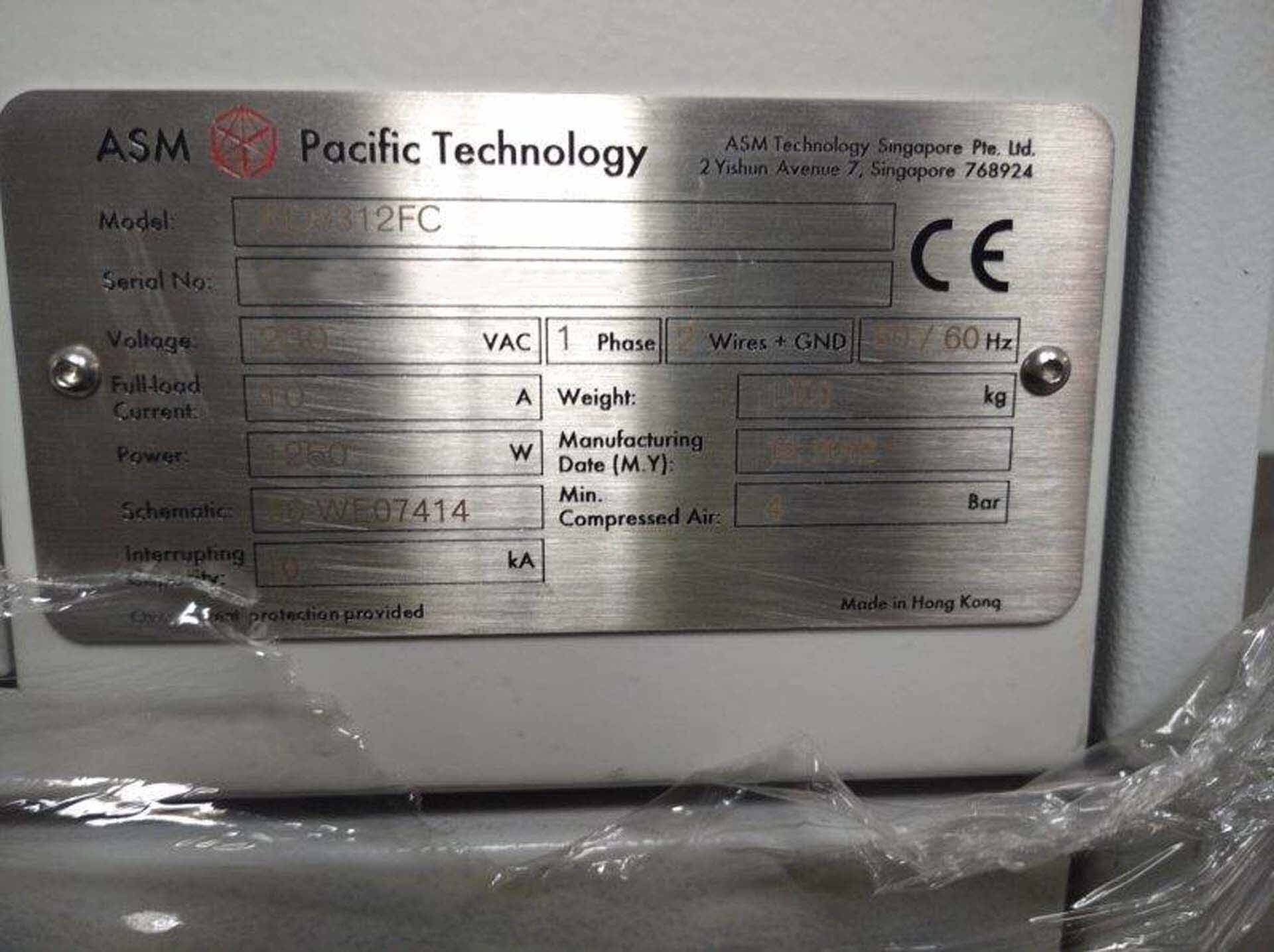

Used ASM AD 8312FC #9360921 for sale

URL successfully copied!

Tap to zoom

ASM AD 8312FC die attacher is a high-speed, fully automated ultra-fine die placement equipment designed to provide precise placement of high-precision and high-power components used in modern-day electronic products. This system is a standalone device that can be utilized for die, SMD chip placement and other high-accuracy applications. ASM AD8312FC utilizes an integrated control unit and high-precision setting means that it can accurately place dies with Repeatability of ±0.02mm, as well as a standard accuracy of ±0.05mm. The machine features an 8-inch color LCD monitor that displays tool settings and other production data. Additionally, the asset supports offline programming through the optional Flash Line Memory and Windows-based software. The ergonomic design of AD 8312 FC allows for easy access to components and workplace materials. It also features upgradable die bonding capabilities, enabling application flexibility. The model has a wide range of turret sizes with up to 12 mounted modules, which can accommodate various applications. The equipment supports an automatic process window detection system that adjusts adhesion pressure in real-time. The unit is equipped with a video-screen detachable camera stand and automated laser sensor. This feature helps with precise placement of dies and other components. Additionally, AD 8312FC features a dynamic temperature control machine to regulate and monitor the temperature during bonding. This allows the tool to guarantee efficiency and performance, while avoiding thermal shock that can damage components. ASM AD 8312 FC supports jet and sump dispensing methods, allowing for precise and efficient dispense of epoxy, and other adhesives. In addition, the asset features rework and repair functions that enable inspection and increase quality process flow. AD8312FC offers a highly efficient and precise die placement process that is ideal for high-end products, improving production line yields and throughput rates.

There are no reviews yet