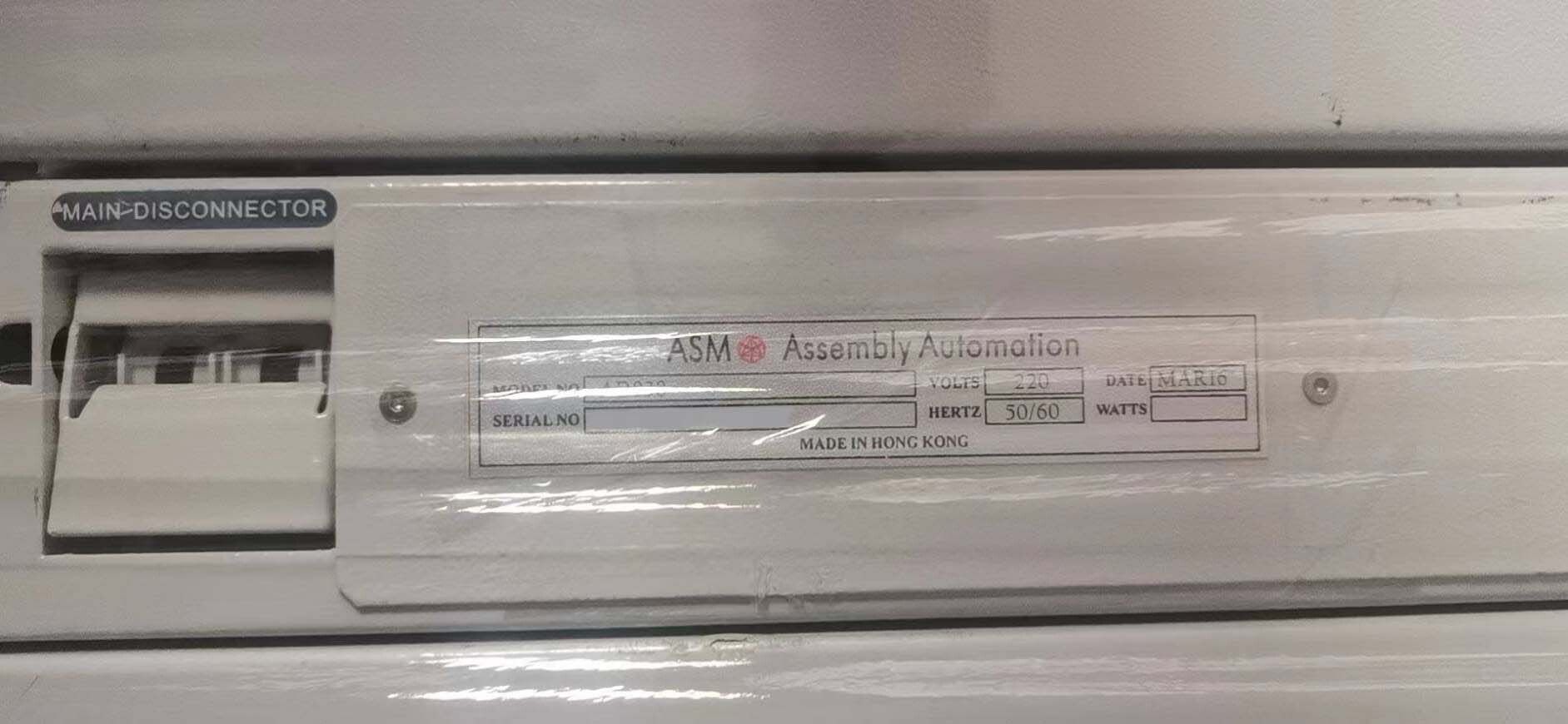

Used ASM AD 838 #293605202 for sale

URL successfully copied!

Tap to zoom

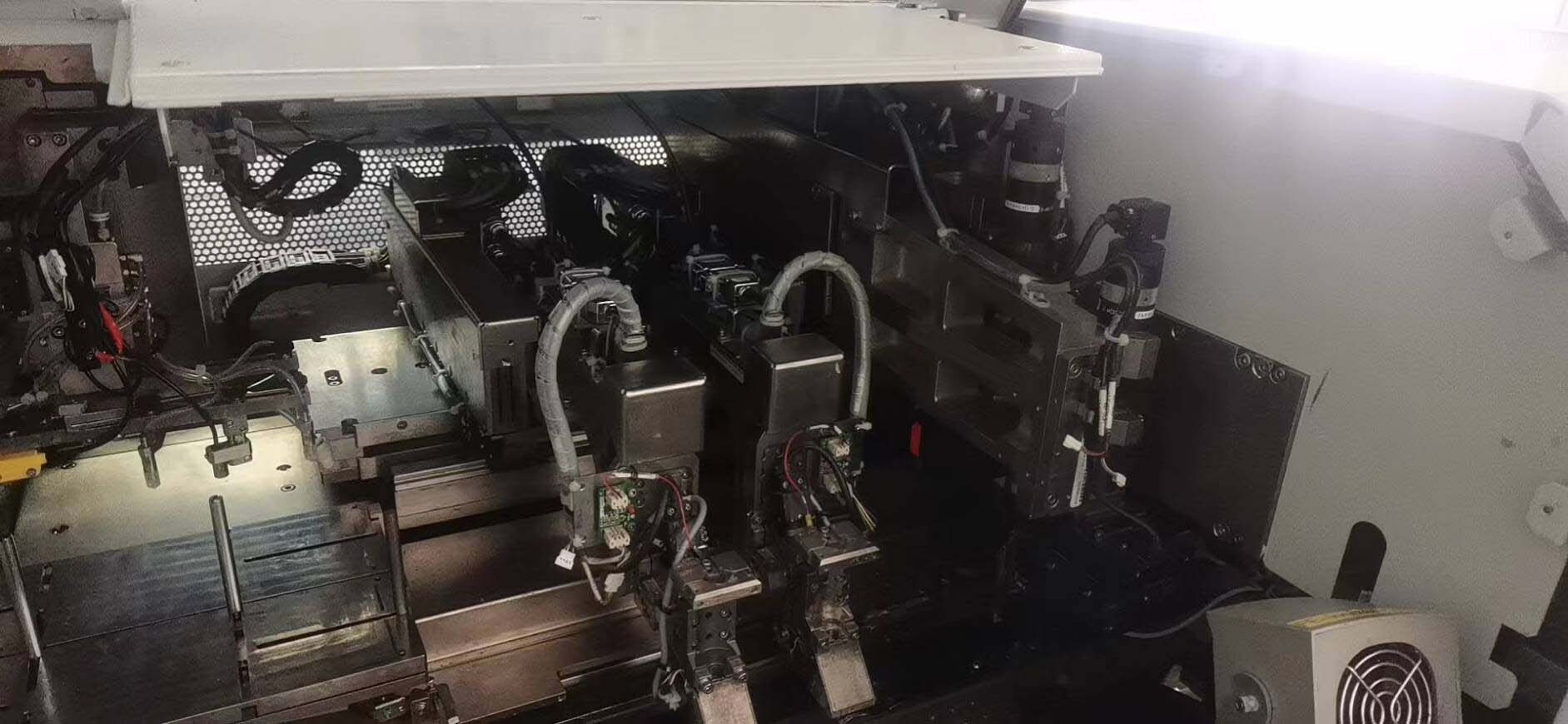

ASM AD 838 is a die attacher produced by ASM International. ASM AD838 is a modern, compact, manually operated die attacher system that delivers a precise, consistent attachment of die assemblies to lead frames. This system boasts a versatile design that can be used to bond a wide variety of electronic components, including tape-bond packages, thermocouples, MEMS, and pure-tin dies. The machine utilizes precision stepper motors and a motorized spindle with a ±3 µm accuracy for precise die placement. It can be configured to attach a single die or an array of dies with a single cycle. It has a noise level of just 37.7 dB, enabling it to be used in low-noise laboratories. AD 838 features a two-axis thermal control, allowing adjustment of the temperature of each individual die, as well as series die attachment. The operator can simply select the setting for number of dies and type of die connection. It has dual spindles for front-side alignment for attaching thick dies, and easy adjustment for attaching thin dies without worries about alignment. AD838 has the capability to bond both wire and tape bond die packages. ASM AD 838 uses an assembly process designed to minimize surface mount resistance. Its versatile design allows it to be used to attach different types of die-attach components to lead frames, while keeping safety in mind through the use of its emergency stop button. It features an impressive speed of up to 20 die/s, allowing for high-speed and precision assembly of intricate parts. The machine's design also allows for ease of use and easy setup, minimizing disruption to production. ASM AD838 is designed with user friendly ergonomic features to reduce operator fatigue. It also has minimal maintenance requirements, with mainly the die cassettes requiring periodic replacements. AD 838 offers flexibility, reliability, and accuracy to ensure maximum efficiency and cost savings for the user. It is well-suited for manufacturing electronic component applications requiring high precision die placement, as well as for customers with tight budgets.

There are no reviews yet