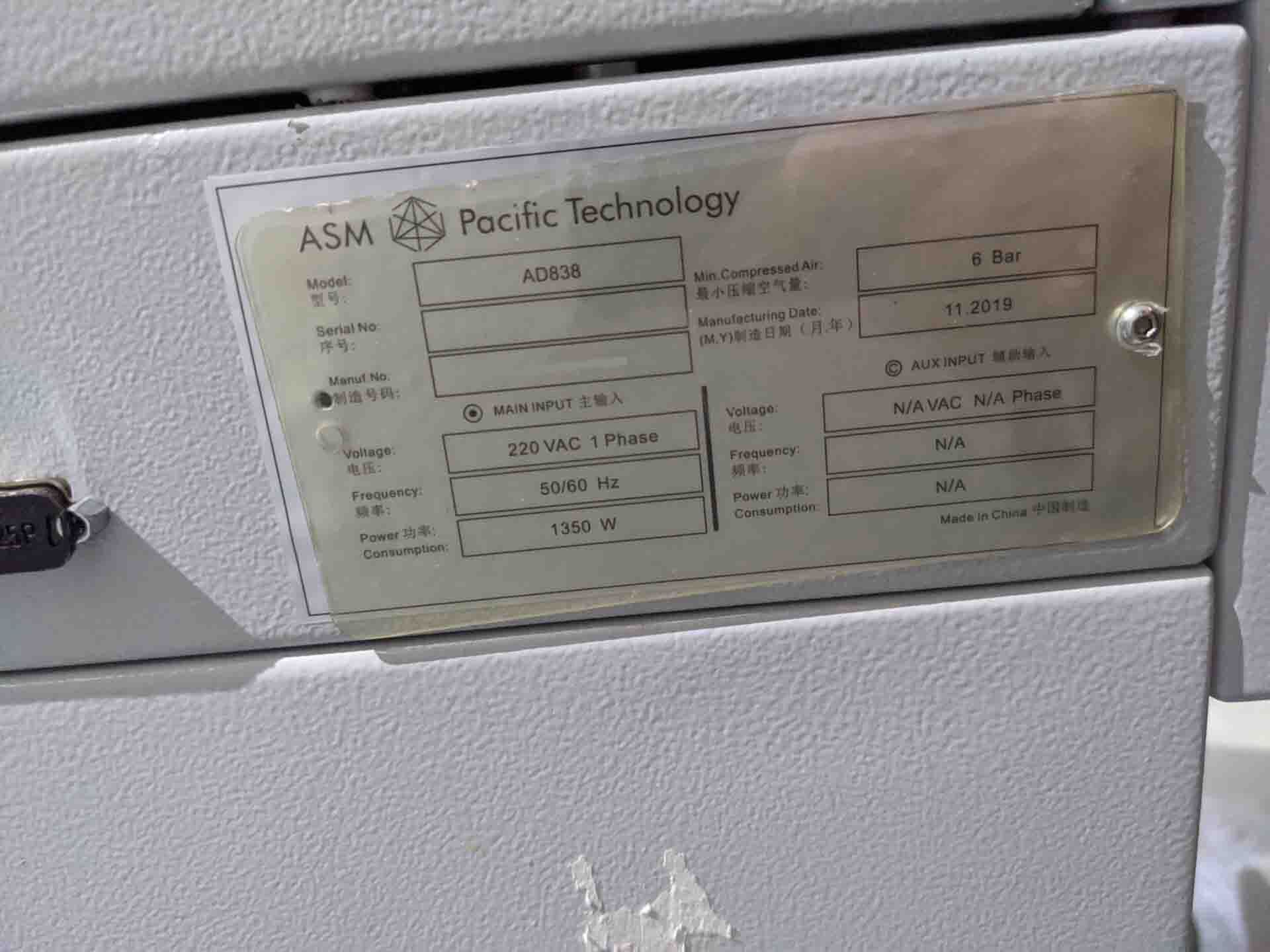

Used ASM AD 838 #293662710 for sale

URL successfully copied!

Tap to zoom

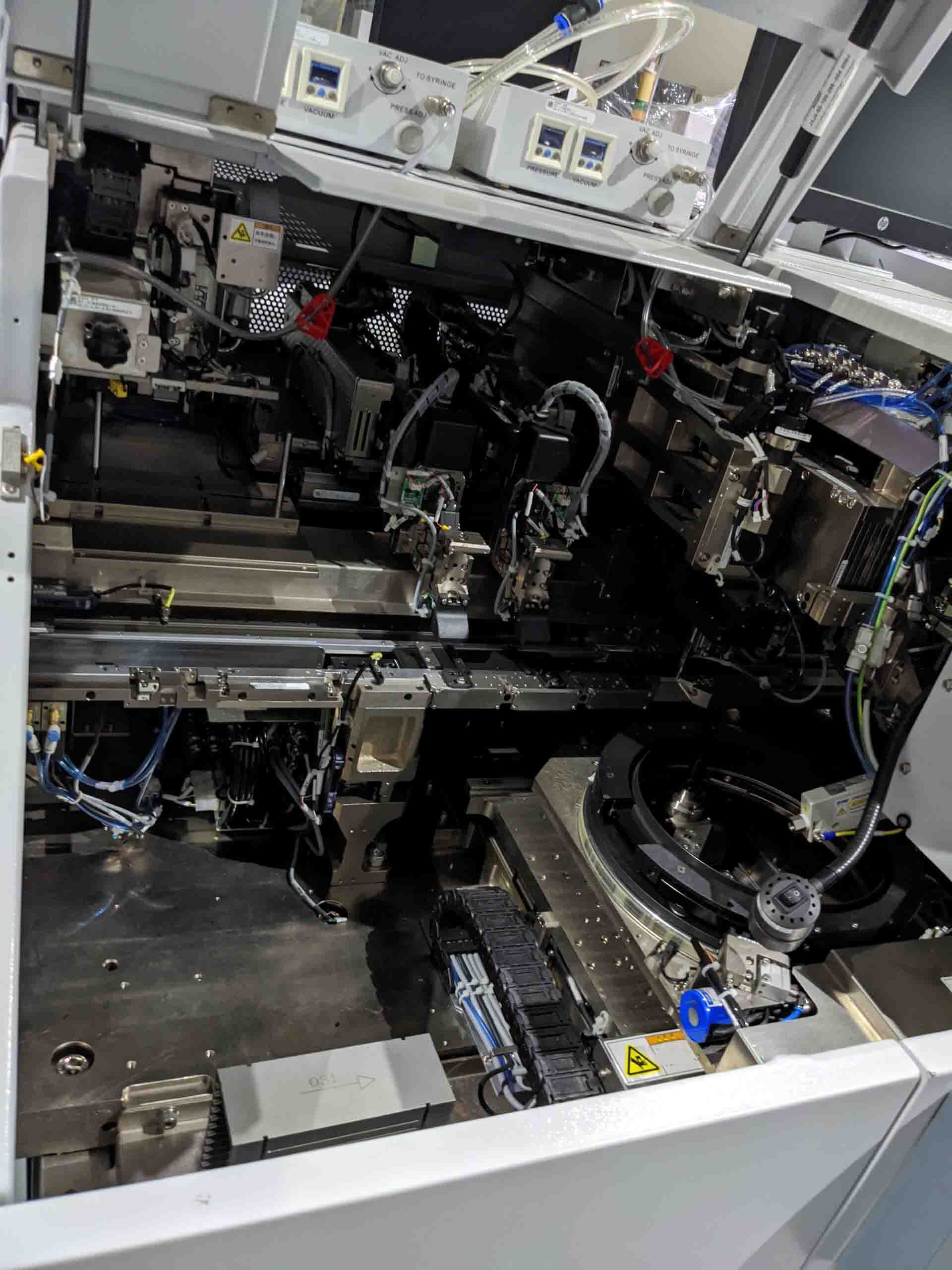

ASM AD 838 is a high productivity die attacher that is used for attaching and connecting component die to lead frames and substrates. It is designed for precision and accuracy, allowing it to be used in high-volume production and high-mix assembly solutions. ASM AD838 is a reliable, automated die attacher with a throughput of up to 8,800 parts per hour. It is capable of attaching die up to 10×10mm in size and has an accuracy of ±25μm. AD 838 is a stable and flexible platform, able to accommodate a range of components from QFPs to BGA. It can also handle a variety of die types, including uBGA, COB, and PLCC. AD838 features an adjustable double-arm head that is easy to set up and adjust, allowing the user to customize the attachment process. The head is also designed to minimize die collisions and reduce the risk of damage. ASM AD 838 is equipped with a rugged pick-and-place head and an advanced vision equipment for accurate die placement. The pick-and-place head is designed for small die, enabling the system to accurately and safely be placed a variety of component die. ASM AD838 is highly user-friendly, designed to be simple to operate and maintain. The unit runs on a Windows-based operating machine, making it easy to learn and use. It also features an intuitive graphical user interface (GUI), which provides visual feedback and control during operation. The GUI allows users to quickly set up and monitor the tool, as well as change settings and parameters. AD 838 works in conjunction with ASM die bump shape variation tool, allowing for precision and repeatability in bump connections. The asset is designed for reliable and repeatable operation, with built-in process monitoring and tracking capabilities. Users can also configure the model to automatically alert them to any potential issues or discrepancies, allowing for timely resolution and preventing any delays or defects.

There are no reviews yet