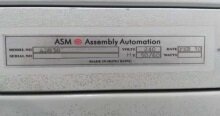

Used ASM AD 838 #9253833 for sale

URL successfully copied!

Tap to zoom

ASM AD 838 is an automated die-attaching equipment that is used to rapidly adhere micro-sized packages in a variety of formats, such as Wafer Level, Flip Chip and Optoelectronic components. ASM AD838 has been designed with a cutting-edge technology to increase productivity and accuracy at the same time. AD 838 is equipped with a vibratory dispensing head and features a full-size 4.3" liquid crystal display. This cutting-edge technology enables AD838 to accurately dispense and place die onto any surface with consistent results. In addition, the precision dispensing head ensures that die are precisely and consistently positioned and secured- without any manual intervention. This intelligent die-attaching system is configured to accurately identify and manage many fine-pitch components- regardless of their shape, size or number of pins. The advanced design of ASM AD 838 offers users many features, including automatic die detection. This helps to reduce errors during the die attaching process by precisely positioning and locating die in each area before adhesive is applied. ASM AD838 also utilizes "smart zone sensing" technology for optimal die placement. It is able to adjust to temperature and humidity, as well as recognize minute gravitational changes, to ensure die are consistently and accurately placed. AD 838 allows for flexible programming of individual components and an attached joystick is available for simple tilt adjustment. AD838 includes a network of servo-controlled motion modules, which enables quicker setup, improved accuracy and allows for precise placement of die. Additionally, the user-friendly graphical interface simplifies operation and provides a rapid, precise way to create a 3-dimensional part. ASM AD 838 is designed to provide safe and reliable die attachment. It has an additional safety feature that recognizes "zero tolerance" components and prevents collisions of die and substrate surfaces. The unit also has an optional built-in machine for monitoring the cure temperature of the adhesive. In addition, ASM AD838 has a low-profile design that reduces the possibility of wafer contamination from adhesive application and static electricity. AD 838 is a reliable, fast and efficient tool that is designed for routine, high-volume production of micro-sized packages. This advanced die-attaching asset offers the highest precision and yield, as well as maximum throughput. With its advanced features and cutting-edge technology, AD838 is an ideal solution for a variety of die-attaching needs.

There are no reviews yet