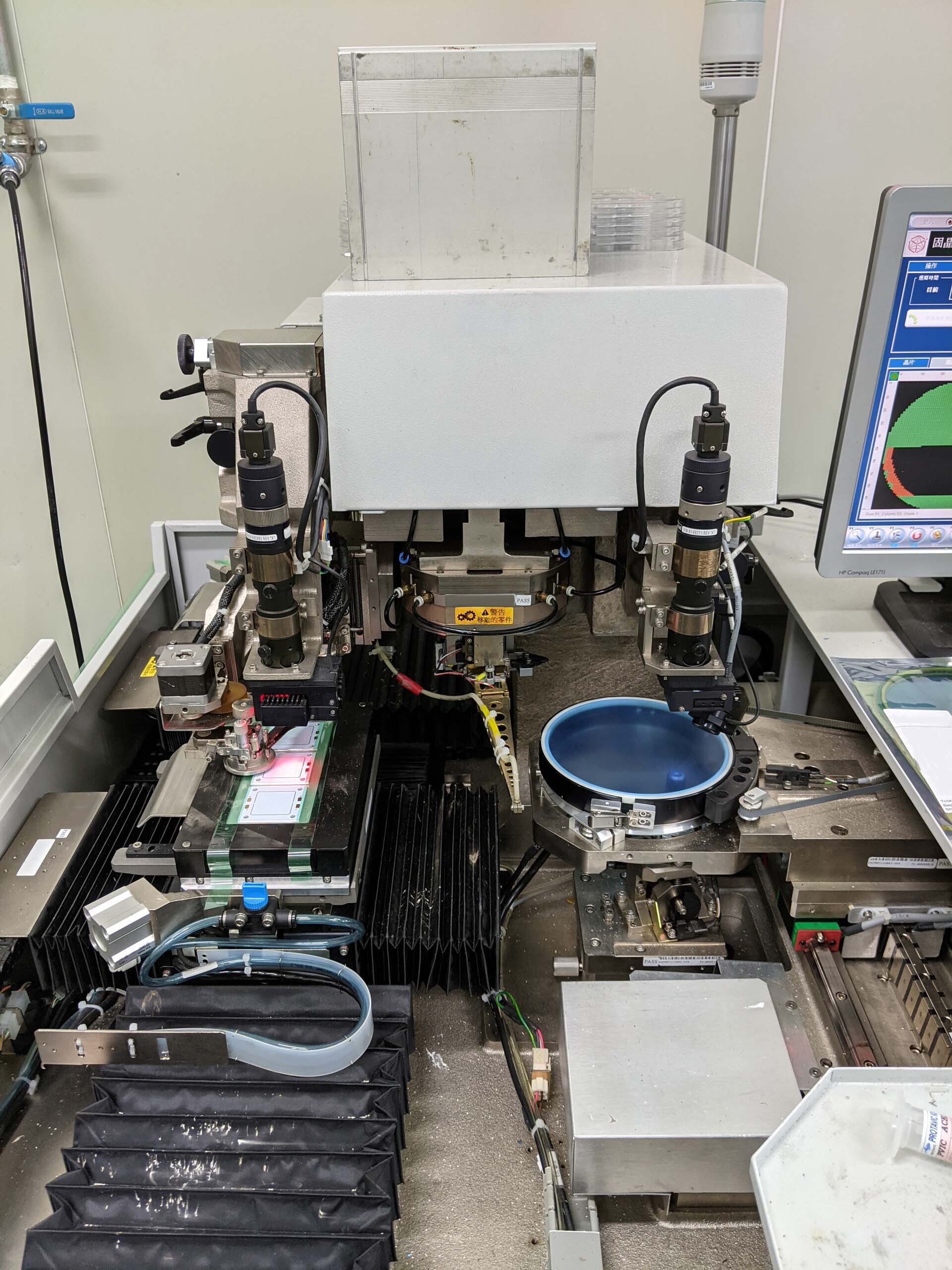

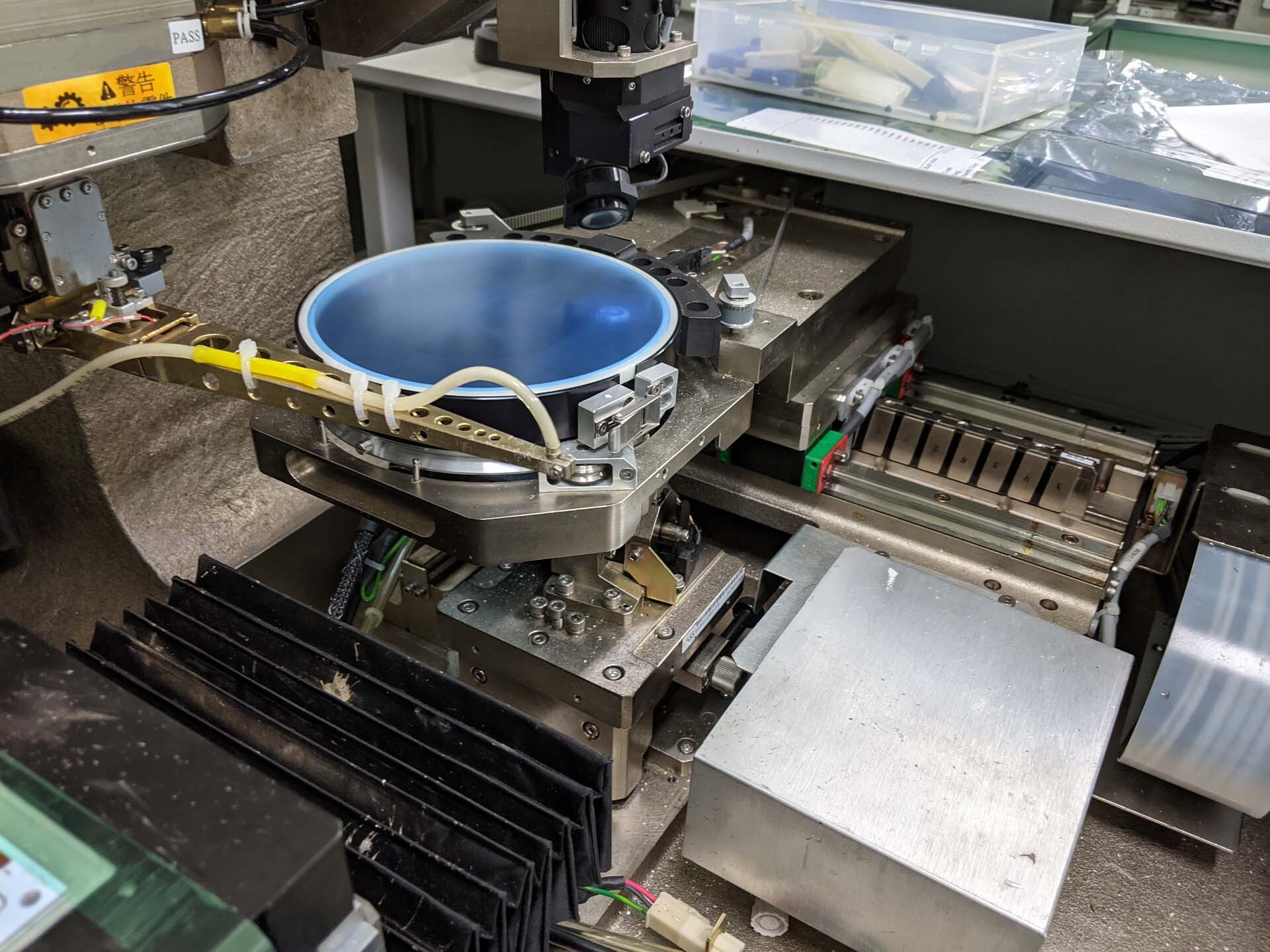

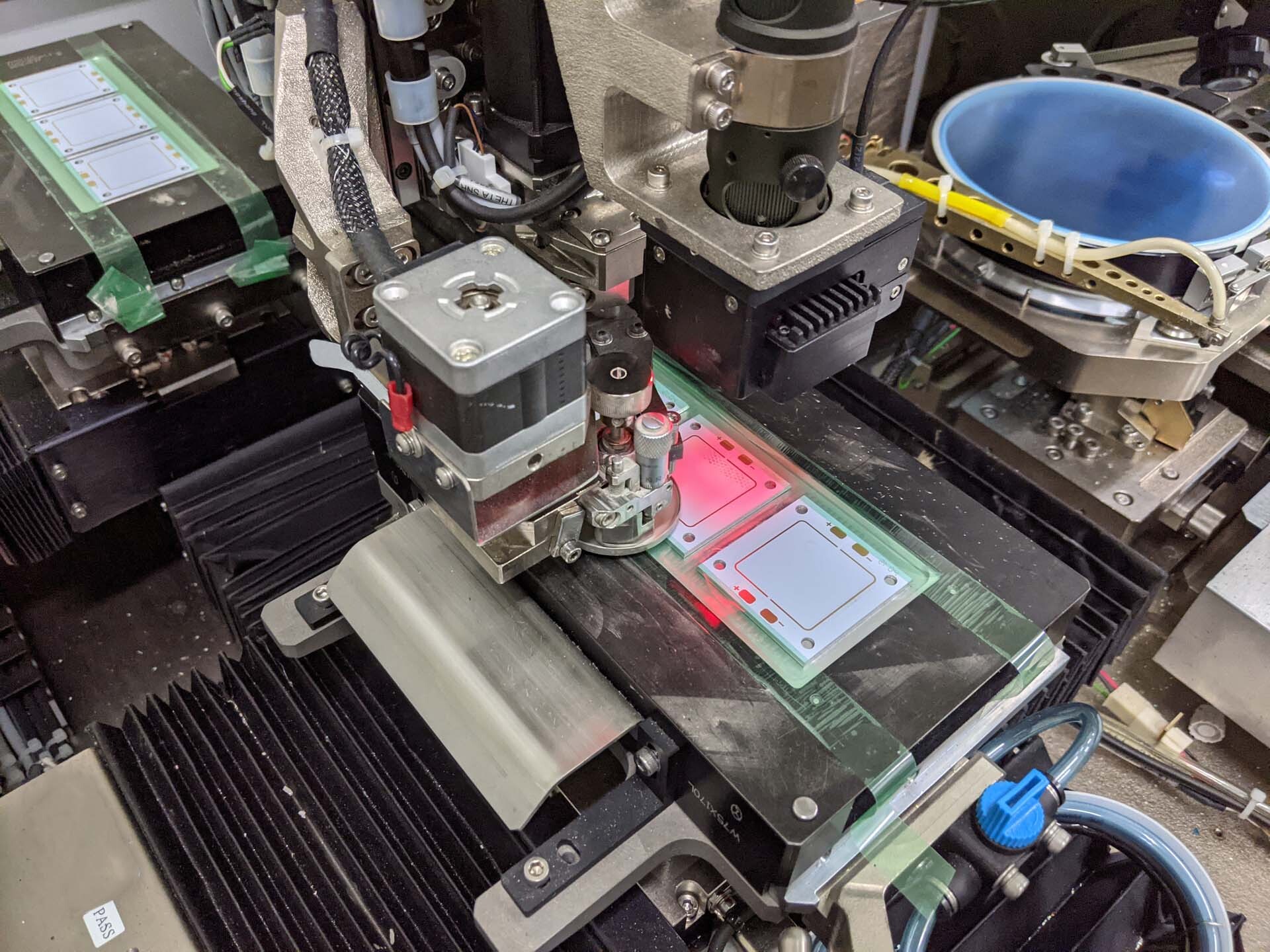

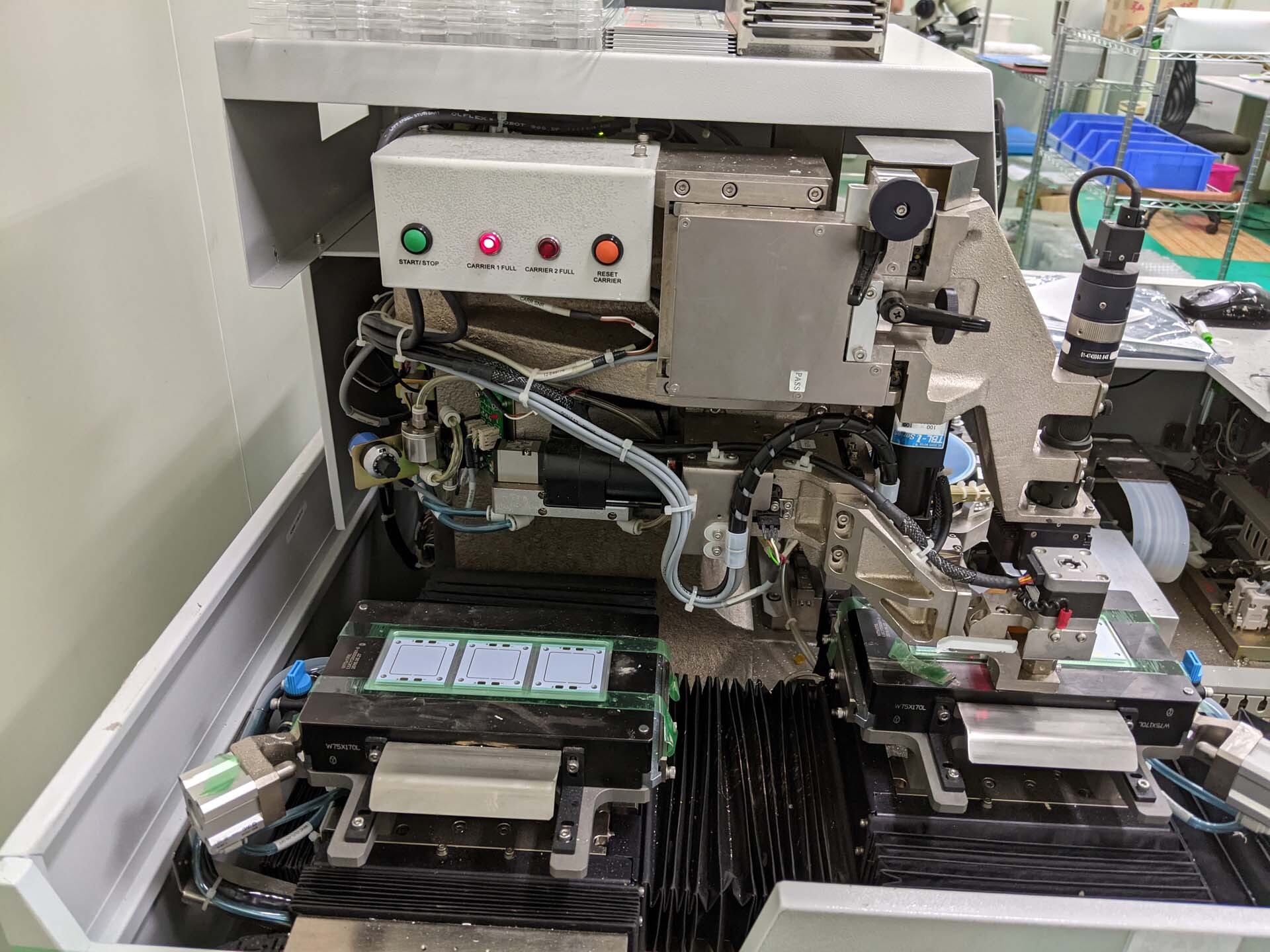

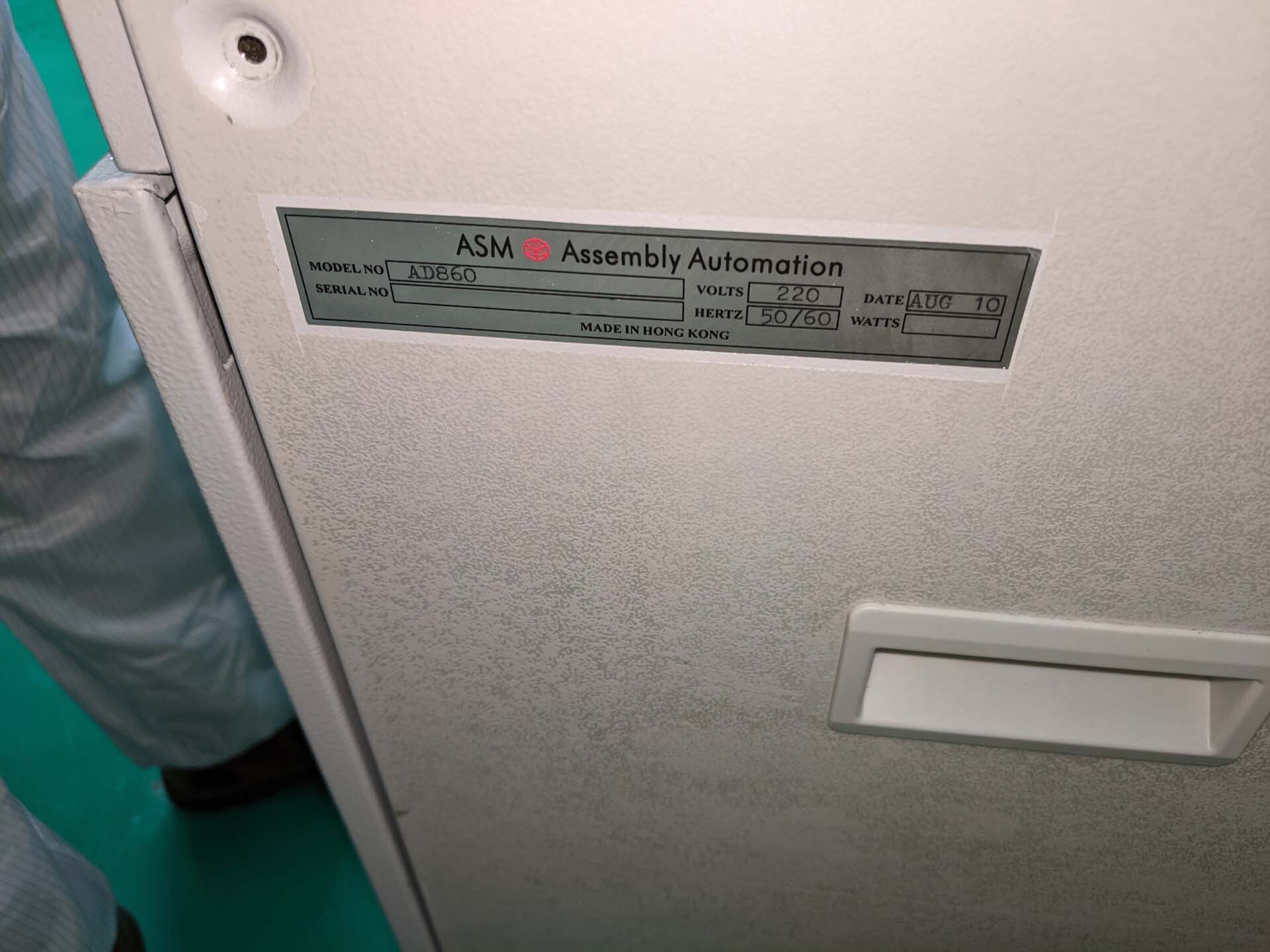

Used ASM AD 860 #9356542 for sale

URL successfully copied!

Tap to zoom

ID: 9356542

Vintage: 2010

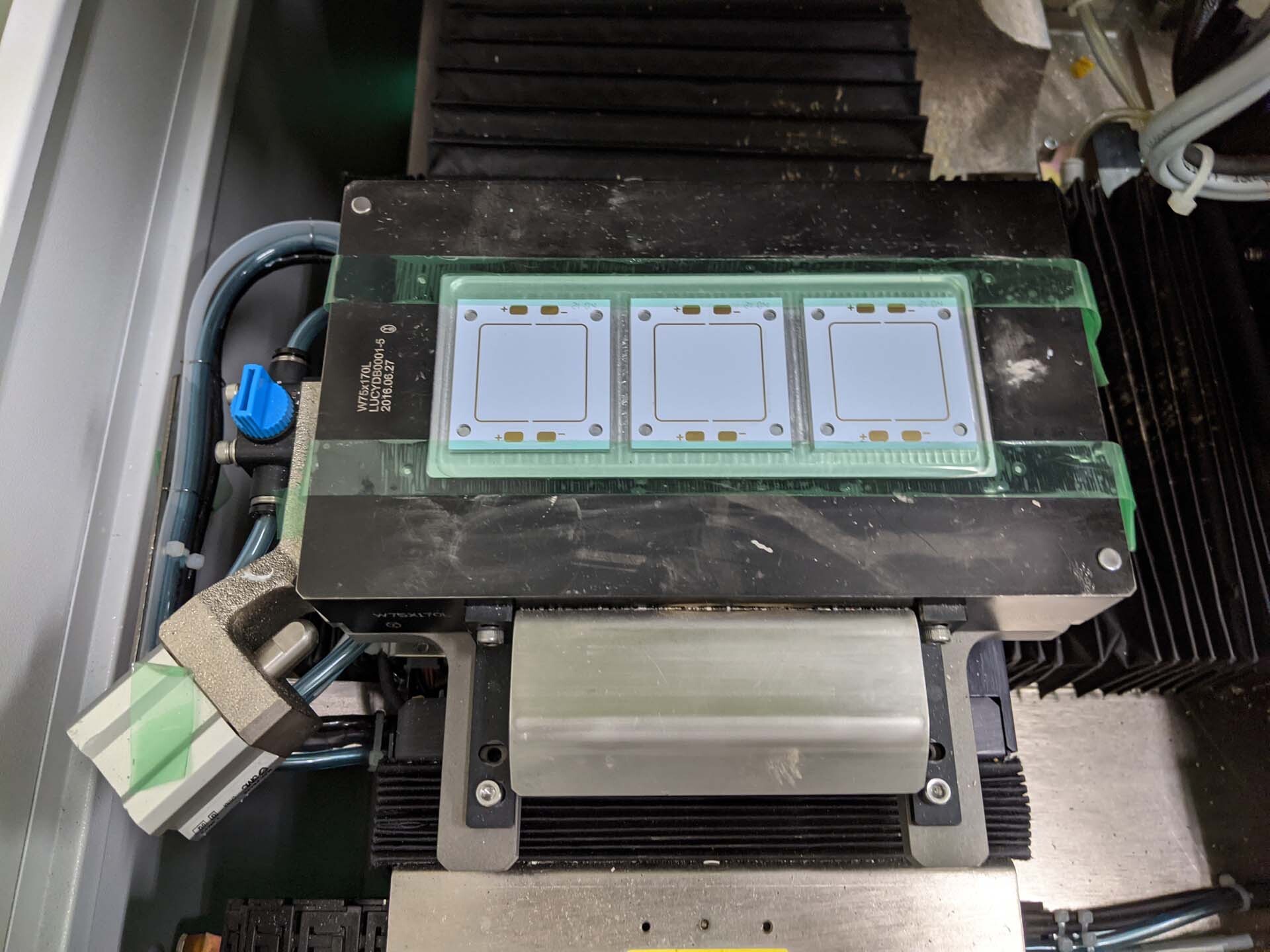

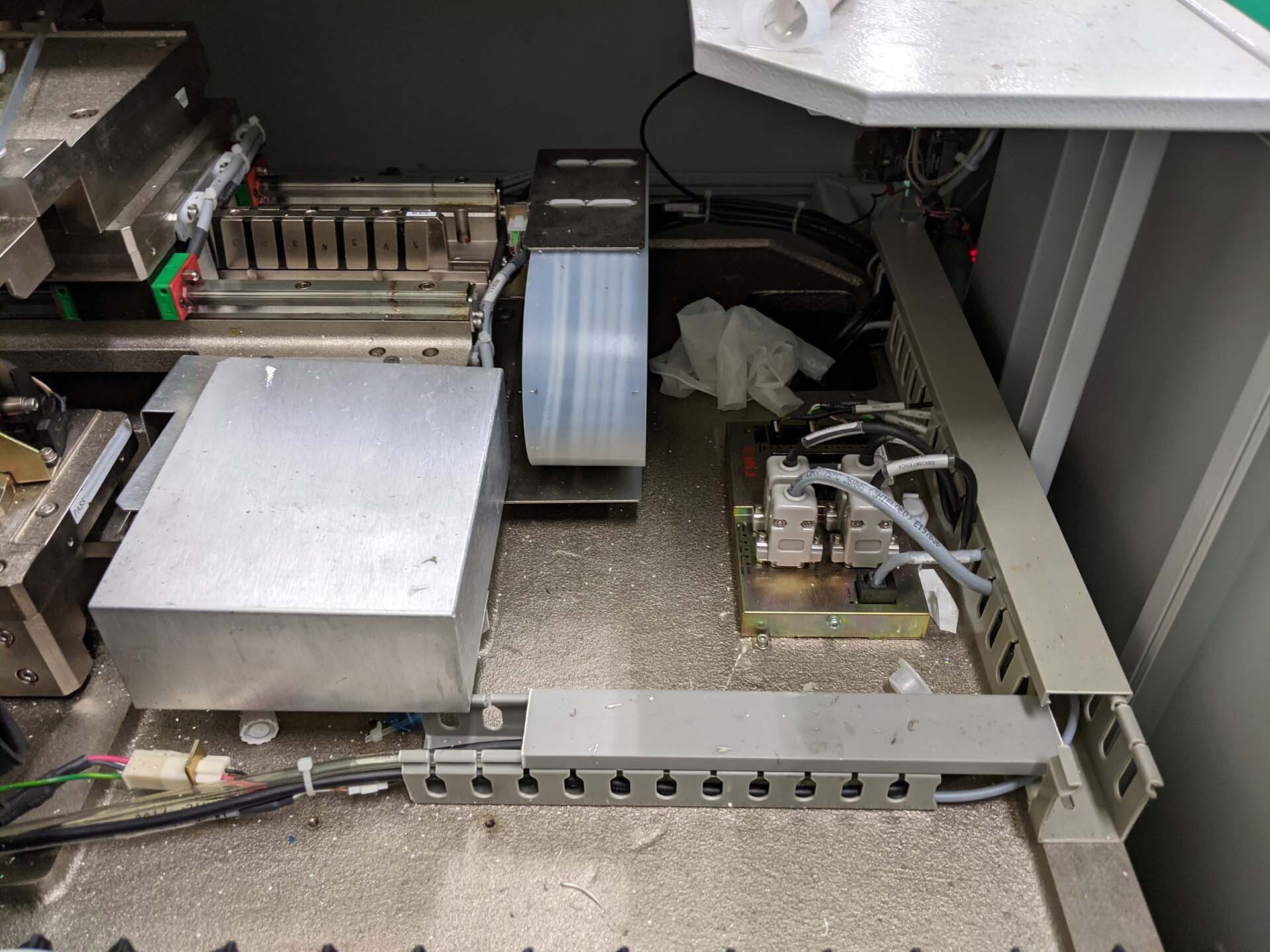

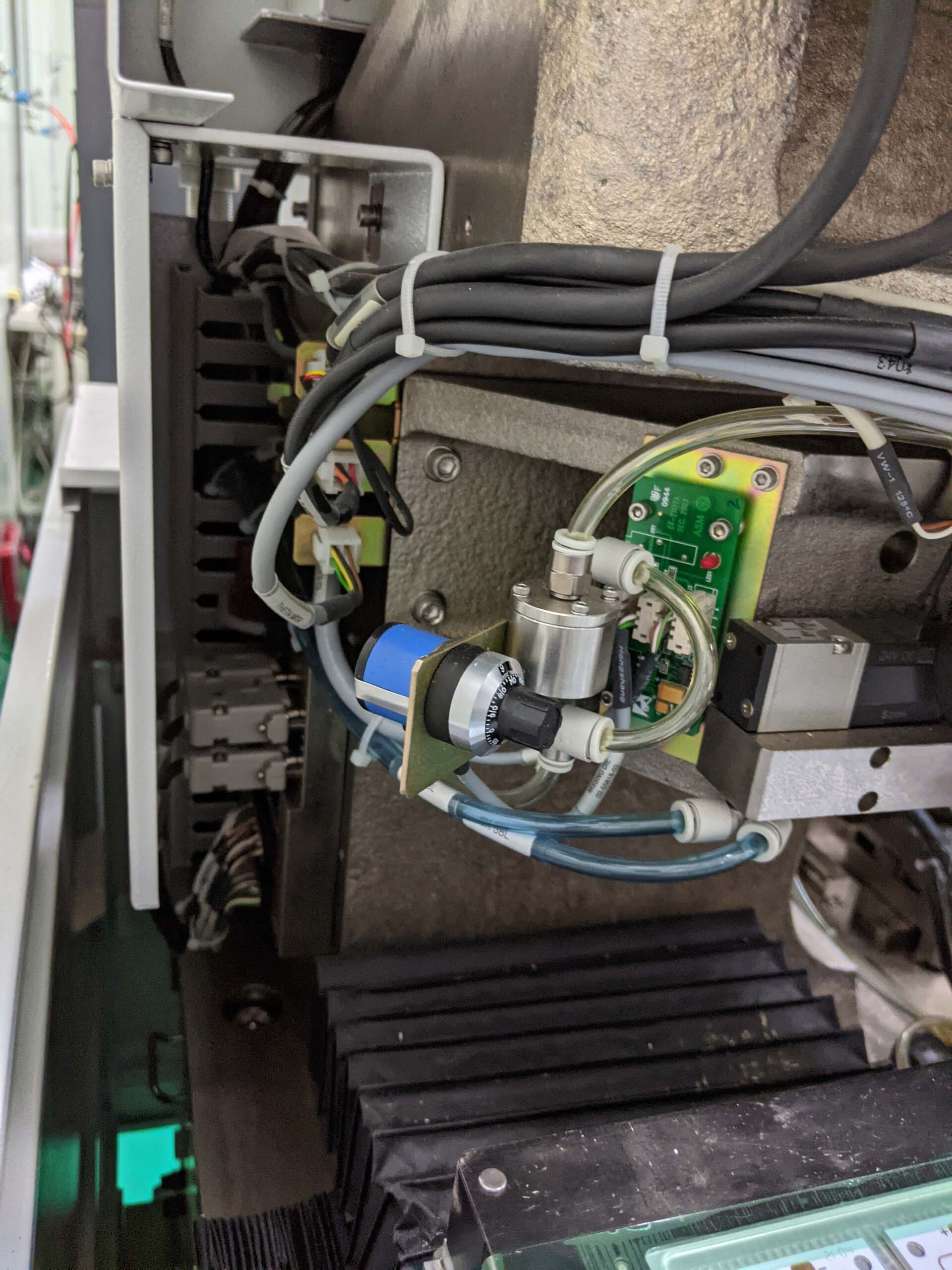

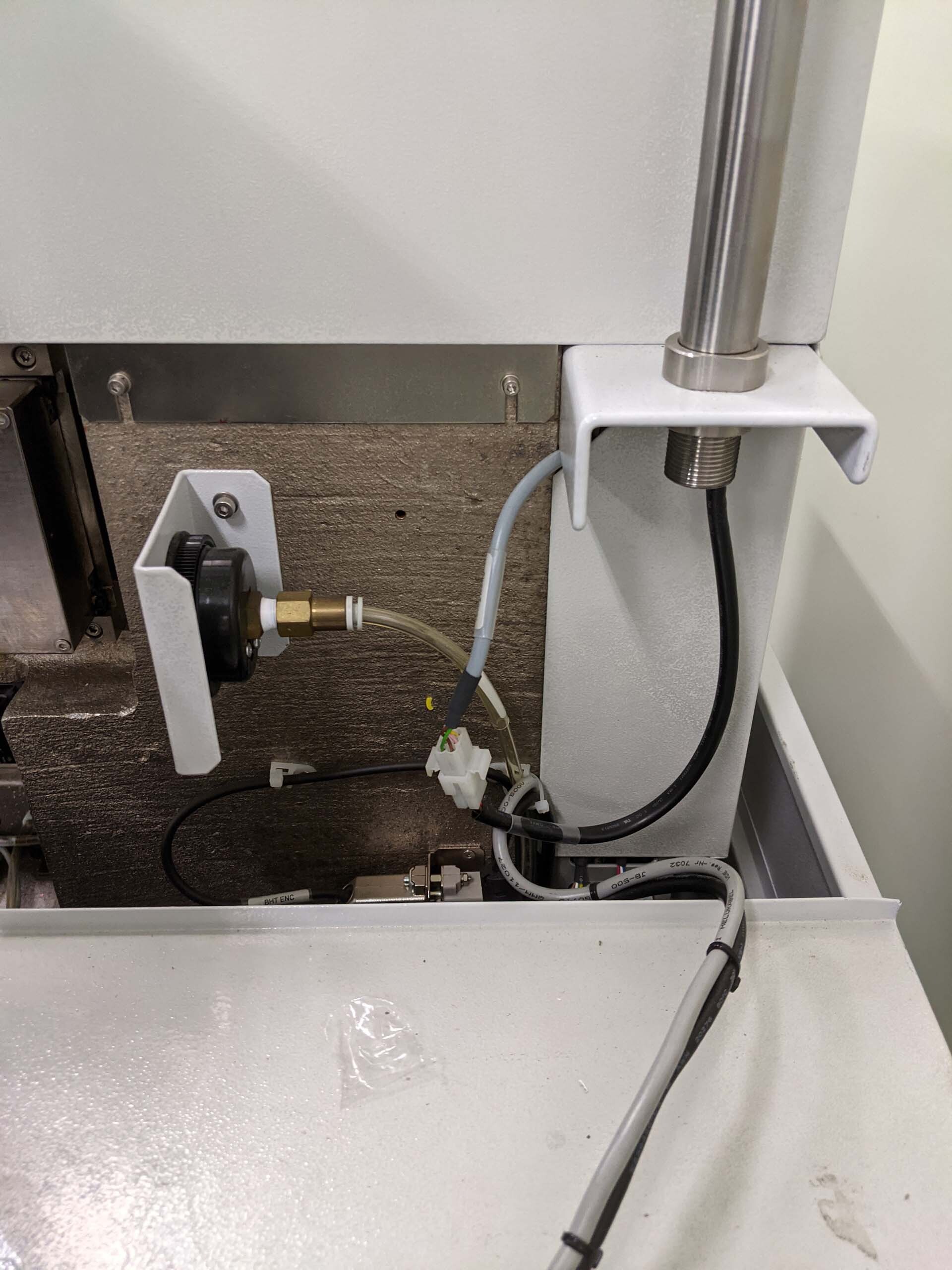

Die bonder

XY Placement: ±1.5 mil (±38.1 µm)

Die rotation: ±3°C

Cycle time: 200 ms

Material handling capability

Substrate size: Maximum (L x W) 8" x 5" (203 mm x 127 mm)

Does not include accessories

Die size:

6x6 mil - 50x50 mil (With PR look ahead)

6x6 mil - 50x50 mil (Without PR look ahead)

2010 vintage.

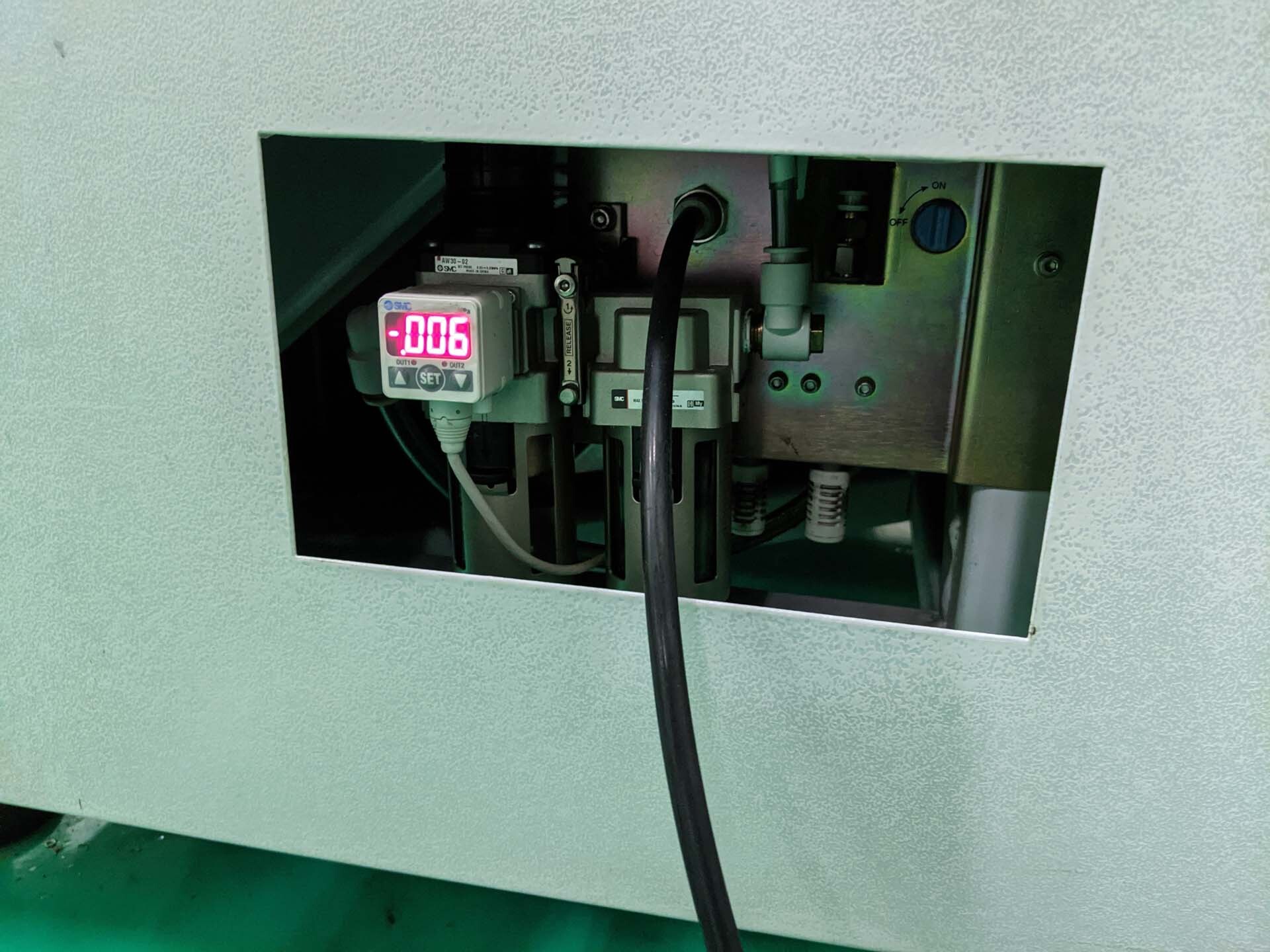

ASM AD 860 Die Attacher is a reconfigurable, durable, and high speed machinery solution designed for applications in the automotive, aerospace, and medical industries where precise metal component finishing is essential. It is a comprehensive multi-functional device that automates the positioning of die cutters, reducing the amount of operator assistance required. ASM AD860 is capable of completing various post-fabrication processes such as attaching the die, deforming, capping, and riveting. Its multi-axis capacitive positioning equipment enables fast and accurate positioning of a variety of standard die cutters. Its cutting head is powered by an air cylinder, providing the user with a wide range of cutting and forming capabilities. AD 860 has a wide variety of safety features, as well as an emergency on/off switch and a cable protection system to ensure the safety of its operators. It is fitted with adjustable self-centering clamps to secure the die to the machine. Its integrated laser beam unit ensures precise positional alignment of dies, allowing for precise and repeatable post-fabrication processes. AD860 also features a graphical user interface and is capable of controlling die cutters with precision in all axes, allowing for user friendly setup and operation. Its tool manager machine is also capable of managing various tools, allowing for automated production and fast tool changes. Furthermore, ASM AD 860 offers connectivity and integration with other systems, allowing for complete process automation and higher production output. Overall, ASM AD860 Die Attacher is a reliable and powerful machinery solution designed for post-fabrication processes requiring accuracy and precision. Its all-in-one design eliminates tool change times, and its efficient operation makes it a great choice for a wide range of applications.

There are no reviews yet