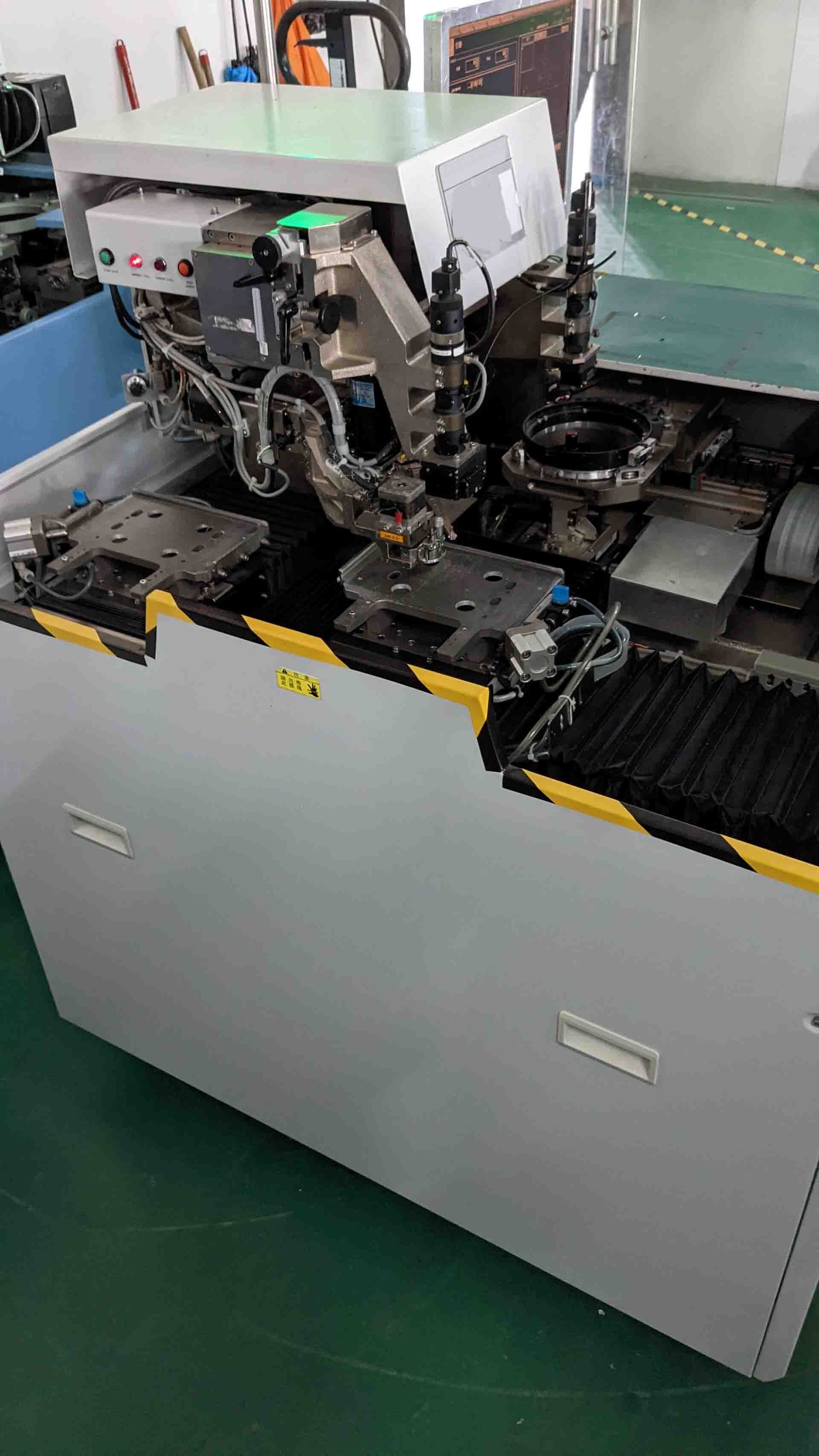

Used ASM AD 860 #9382571 for sale

URL successfully copied!

Tap to zoom

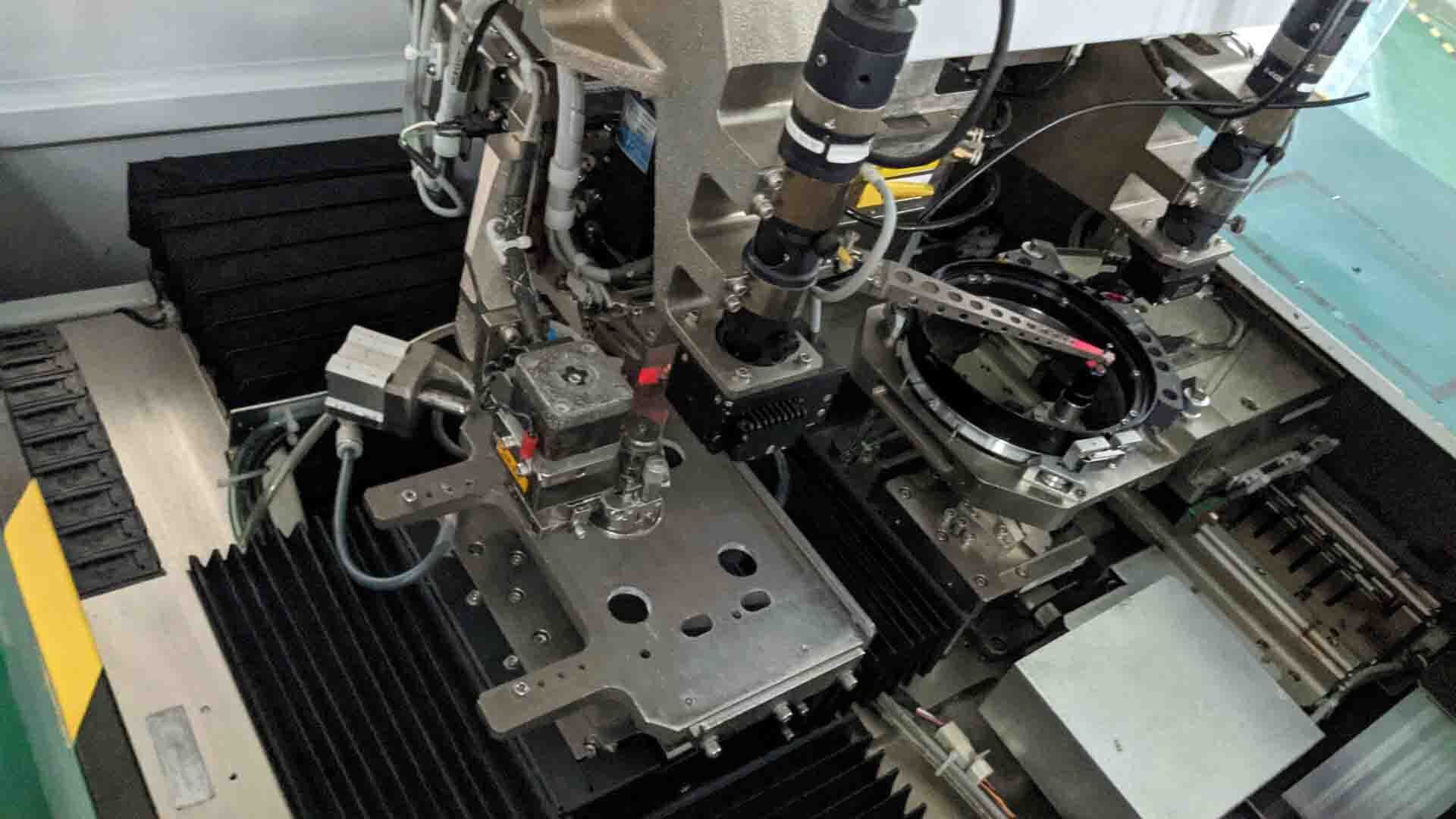

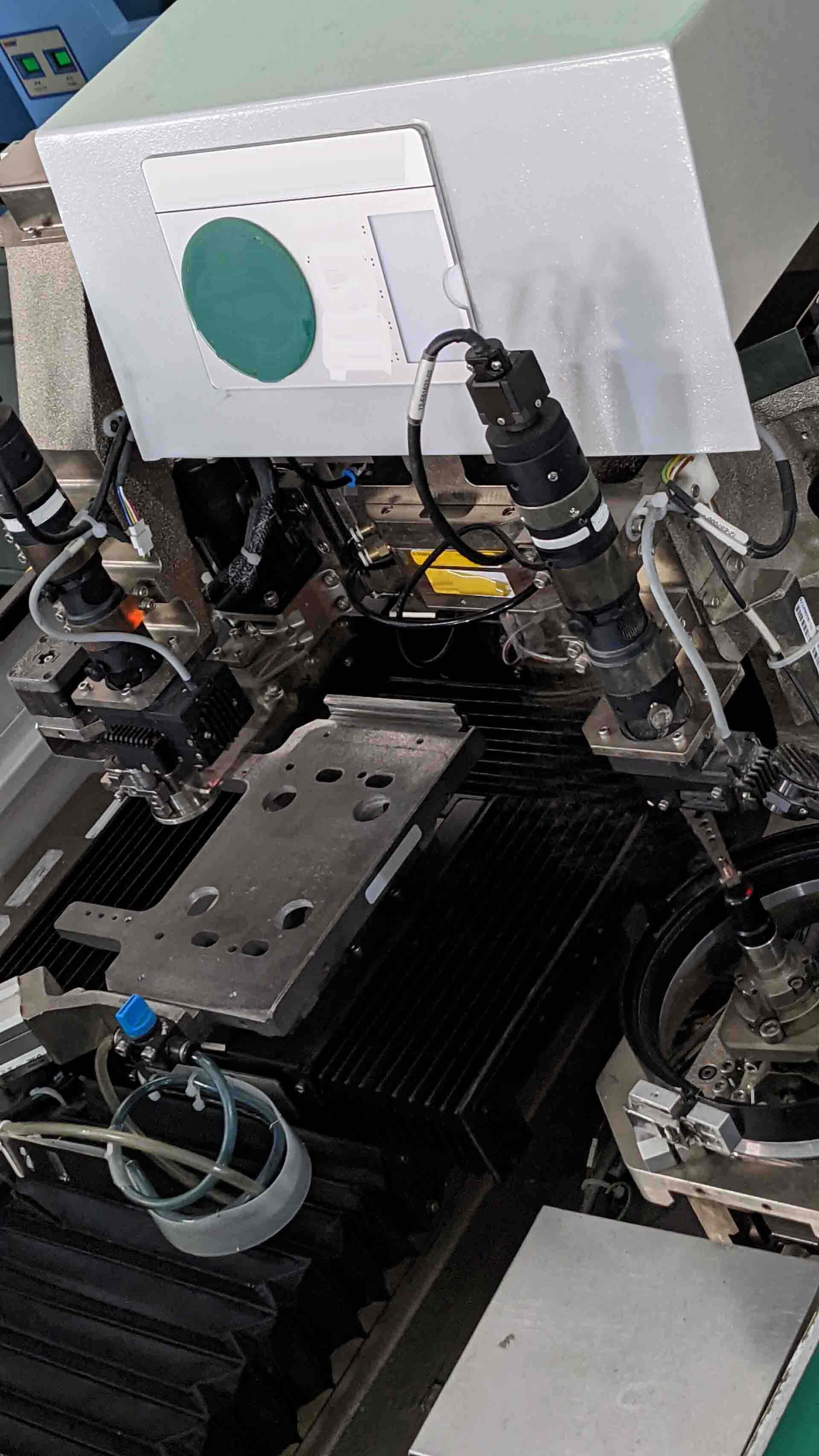

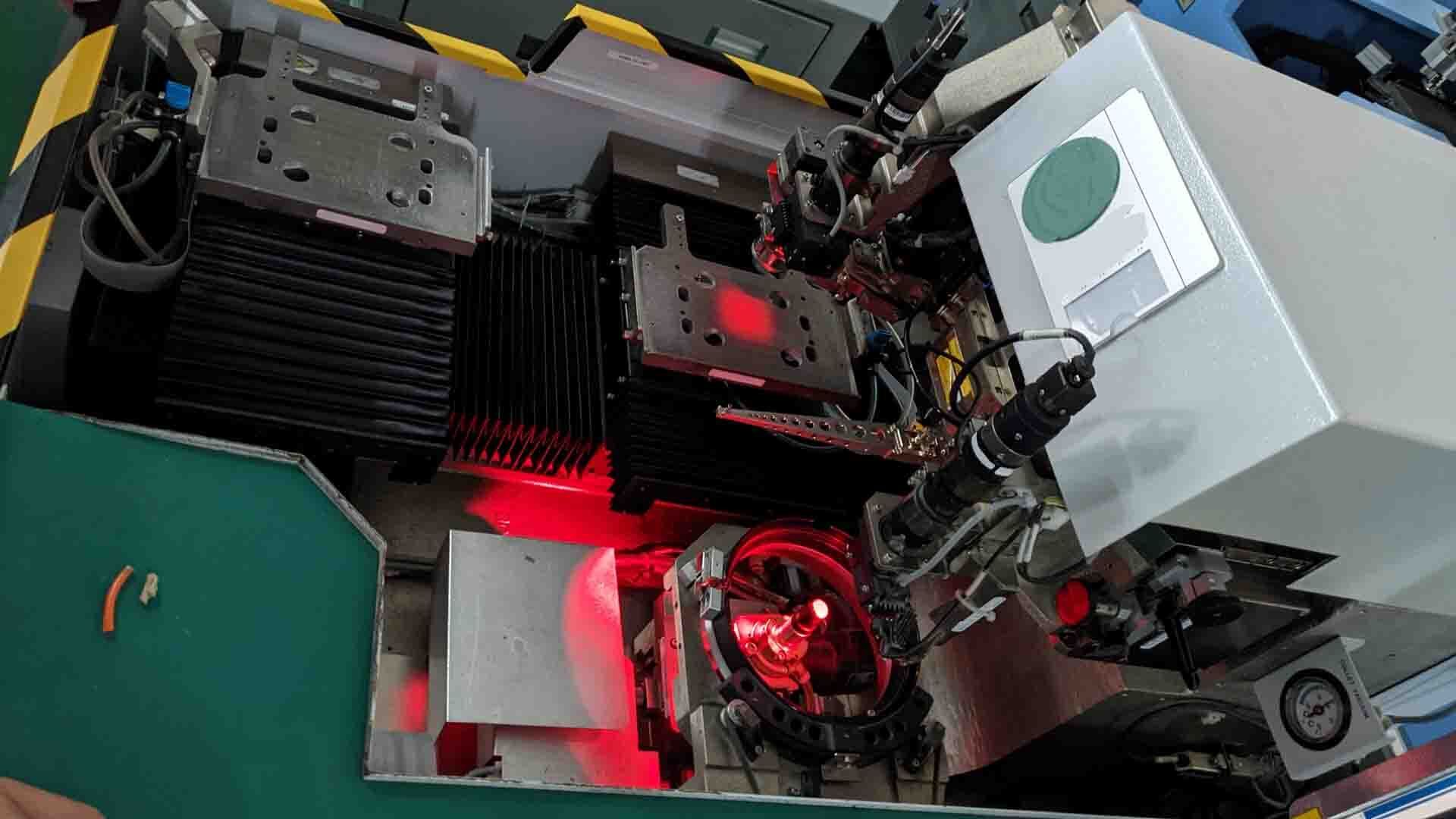

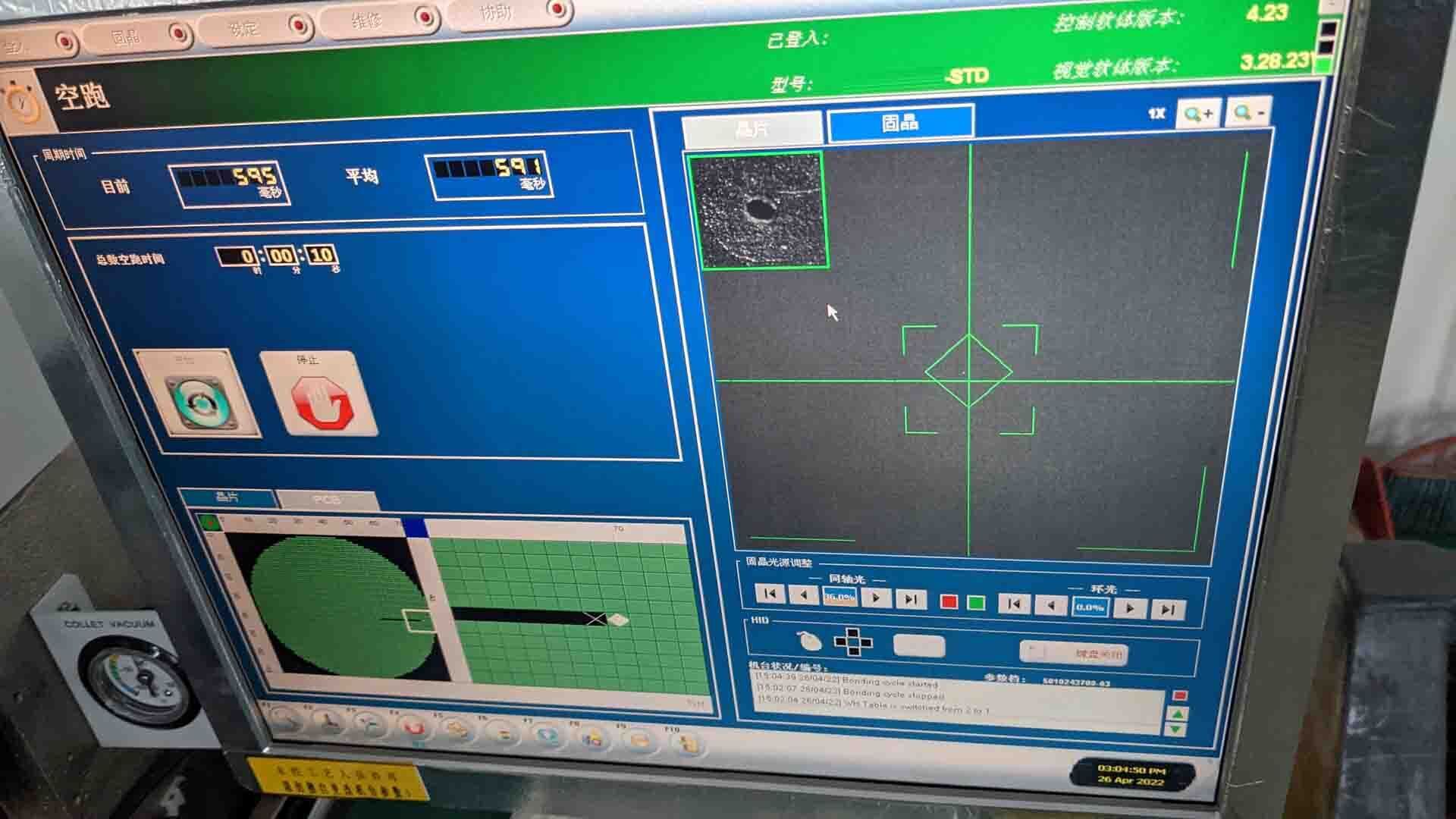

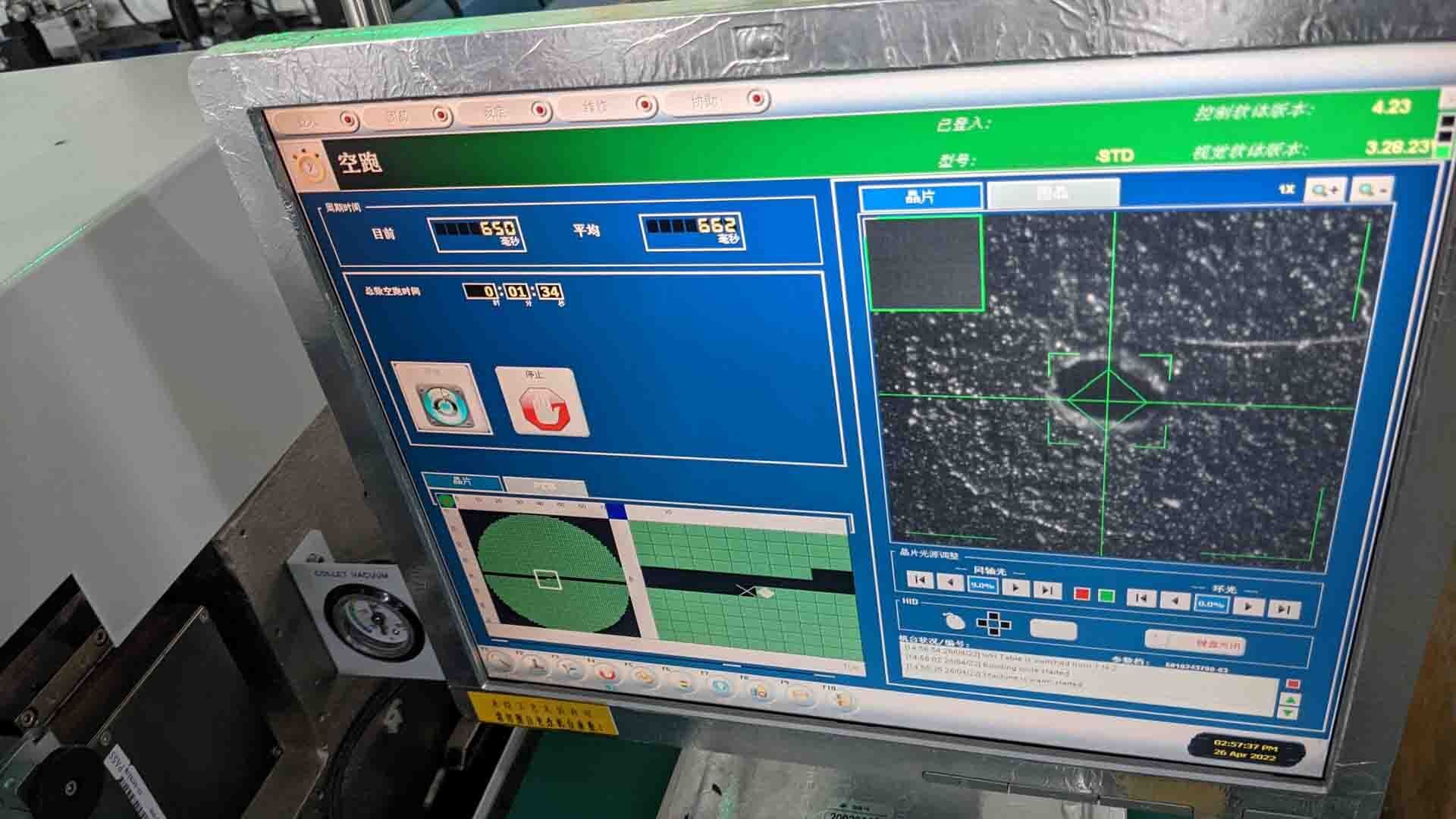

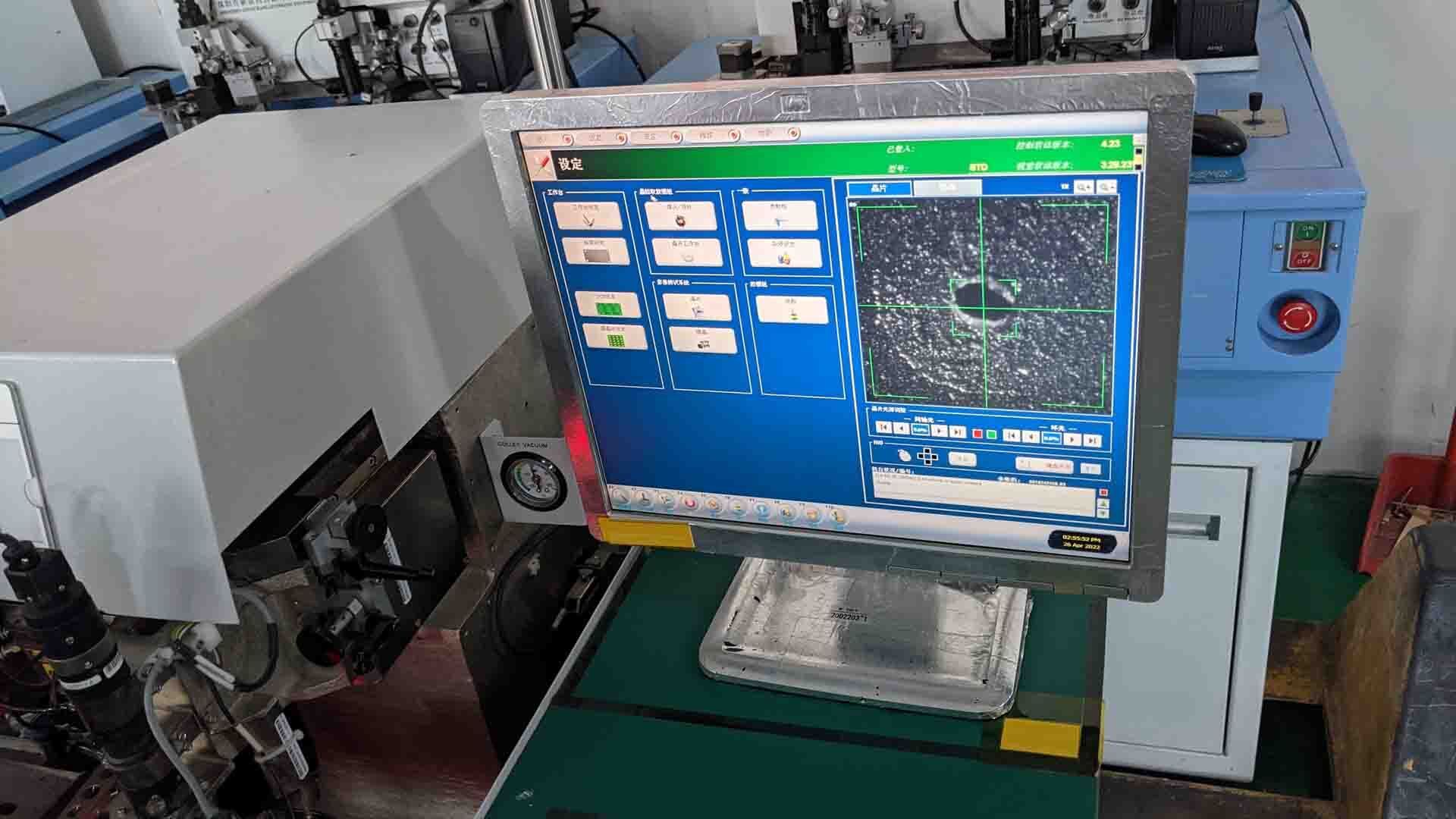

ASM AD 860 is a die attacher designed for reliable die-bonding (silver and gold-plated) and die-siliconization (siliconizing or coating) operations. It is a robust, cost-efficient and high-capacity tool which offers good return on investment. The die attacher features an intuitive user interface which facilitates easy and efficient setup and operation. It comes with preset parameters for the set-up of die-bonding and siliconization operations, reducing set-up time. The process parameters are selectable through the display screen or the optional footswitch. ASM AD860 has a thermal evaporation method that allows for gold, silver, or palladium wire die-bonding and siliconizing. It is equipped with a footprint plate, allowing for rapid die placement, and external vacuum port for die pickup. This allows the user to quickly and accurately place and attach dies. The machine also features a built-in safety as well as high accuracy thanks to a die-to-die repeatability of less than 0.03 mm. With its low noise level and ESD protection, AD 860 is safe to operate even in sensitive environments. The die attachment process is made easy by a built-in vision system which allows for setting up of precise parameters (such as die location) before the process is started. Furthermore, it can be integrated with a microscope/camera for high-precision die sighting. AD860 is also equipped with a forced-air cooling system attached to the silicone tank, which ensures reliable die-bonding and siliconizing procedures even in high temperature operating environments. Overall, ASM AD 860 is an invaluable tool for manufacturing and industrial processes that require precise die-bonding, siliconizing or coating operations. Thanks to its various advanced features, this machine offers excellent cost-efficiency and high return on investment, making it an ideal choice for any industrial application.

There are no reviews yet