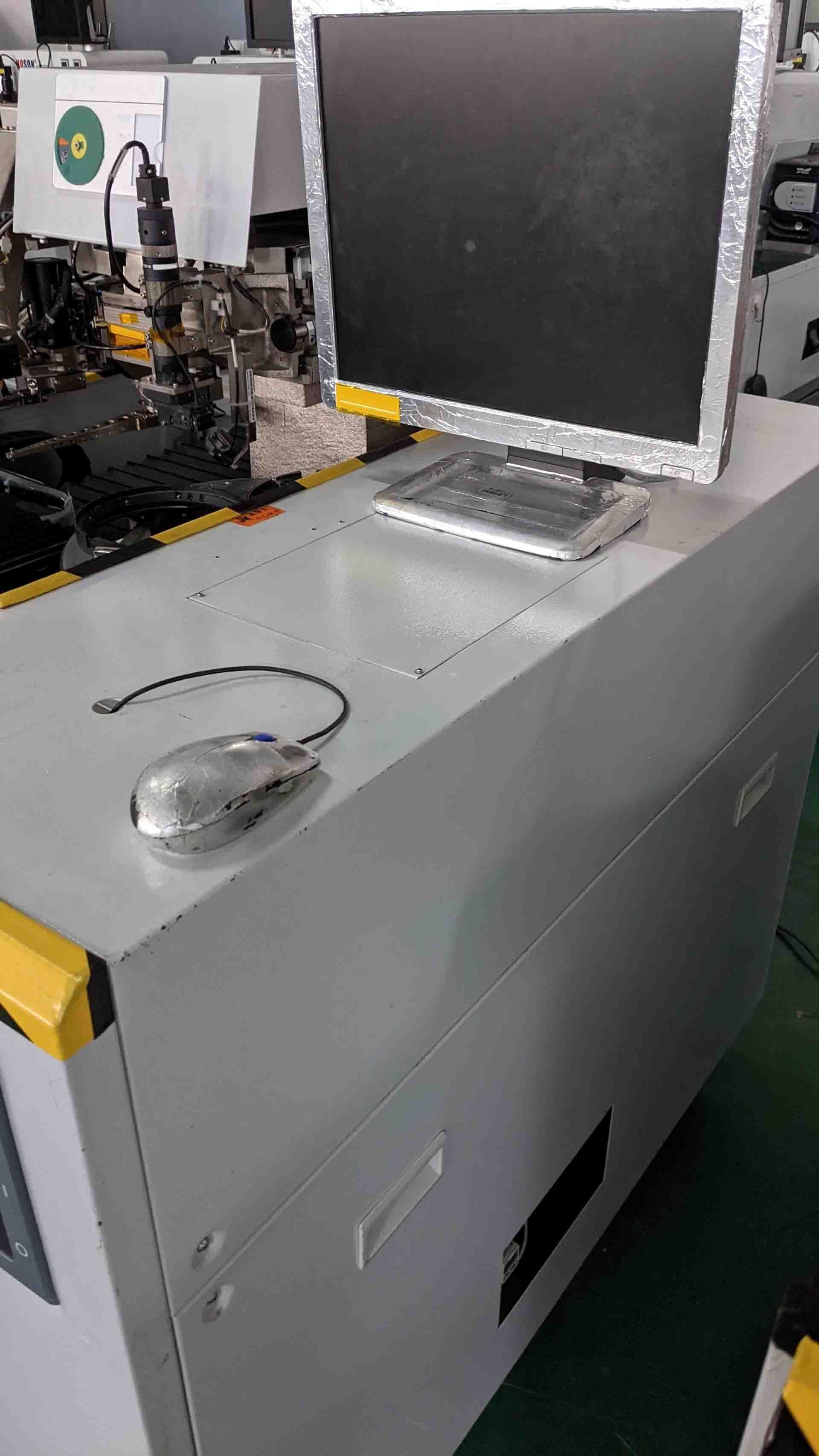

Used ASM AD 860M #293604440 for sale

URL successfully copied!

Tap to zoom

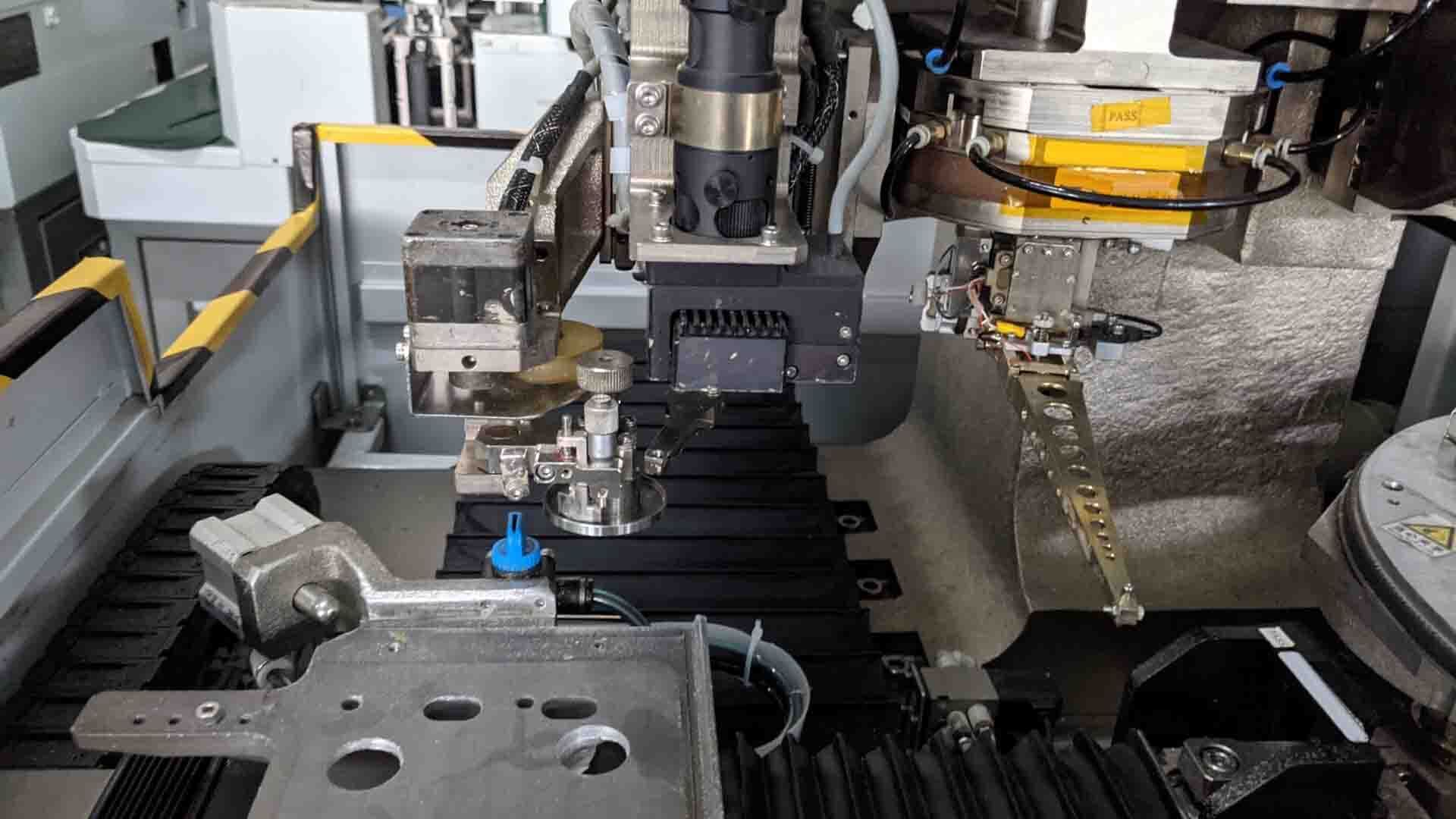

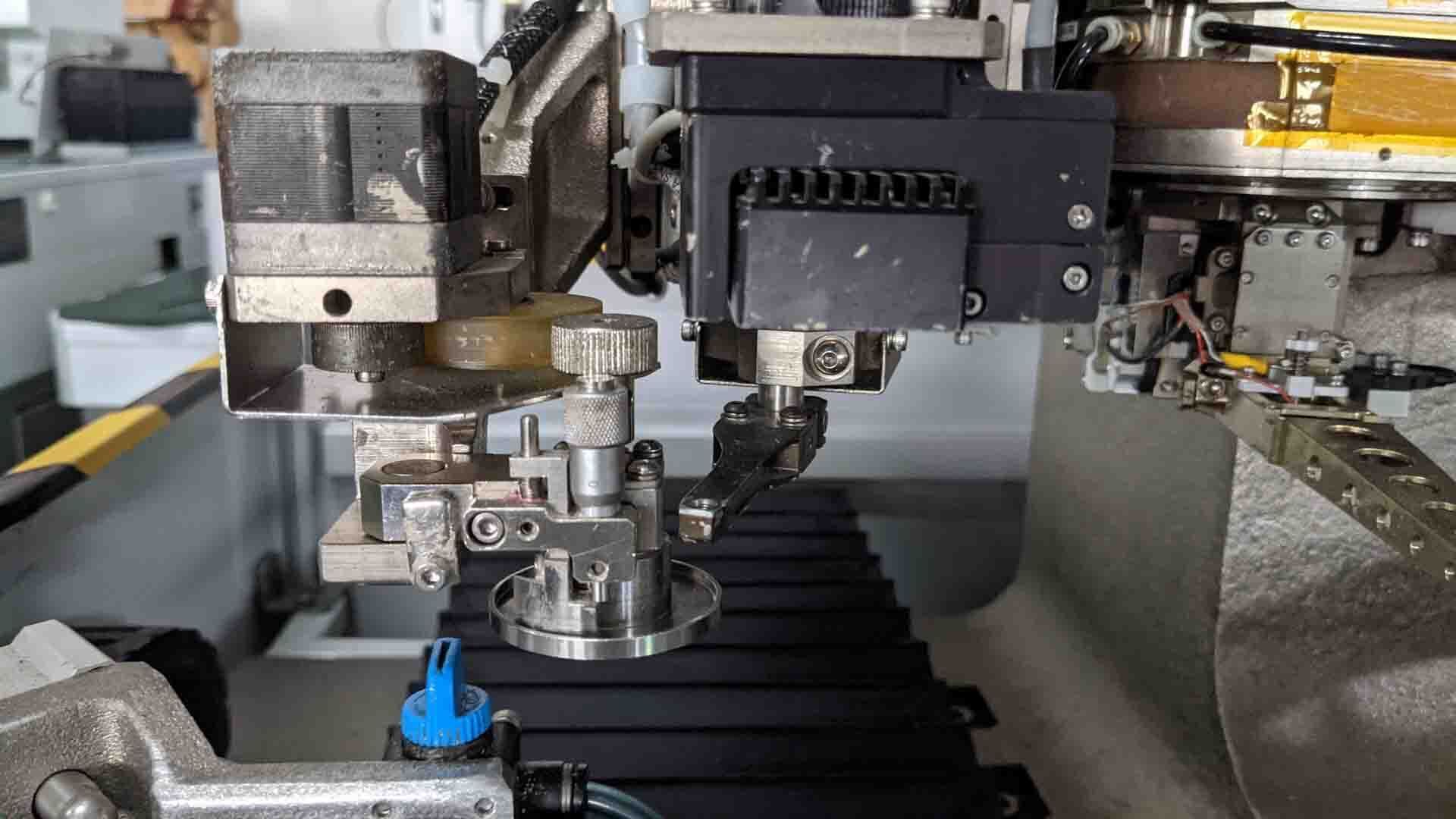

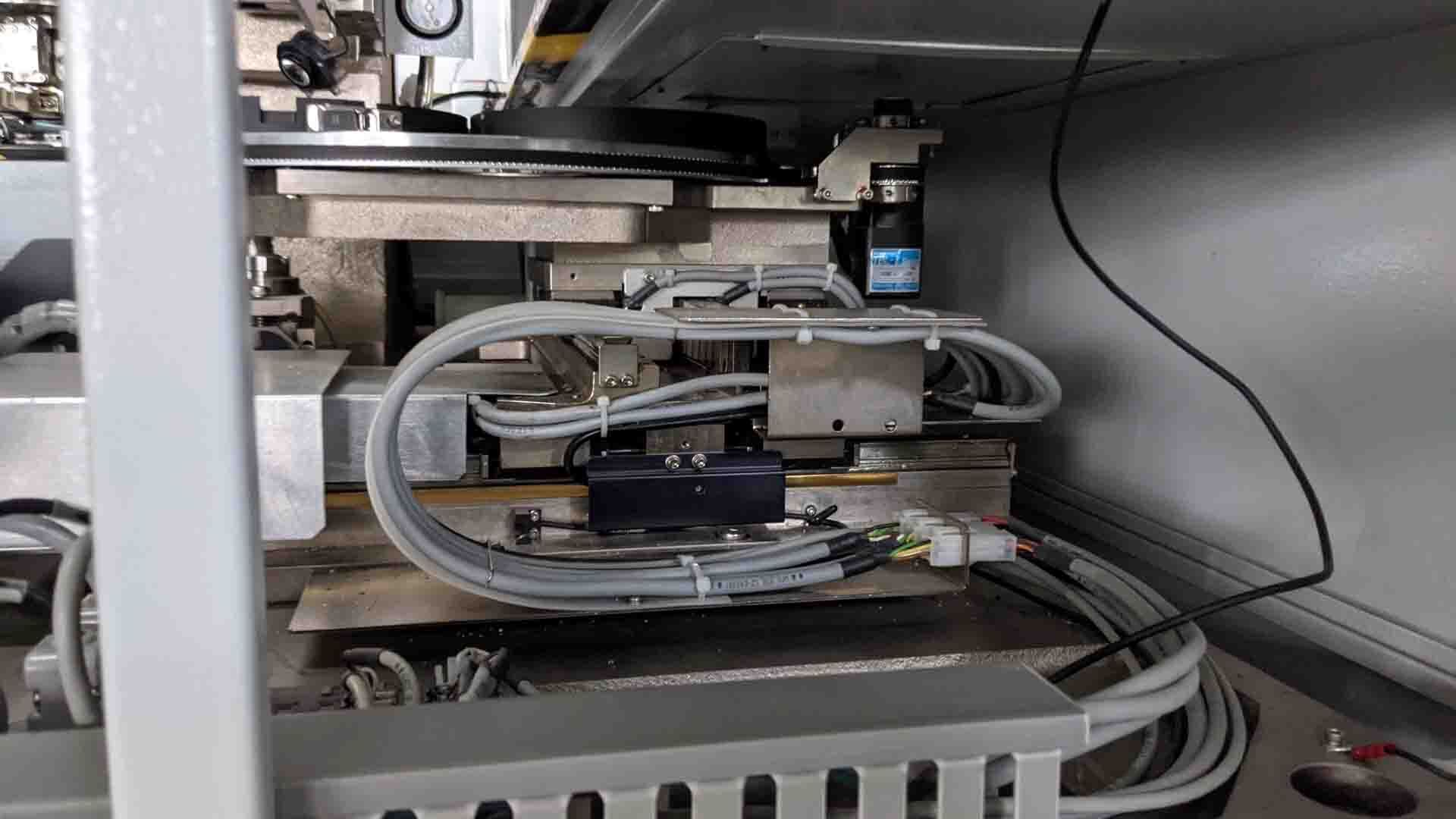

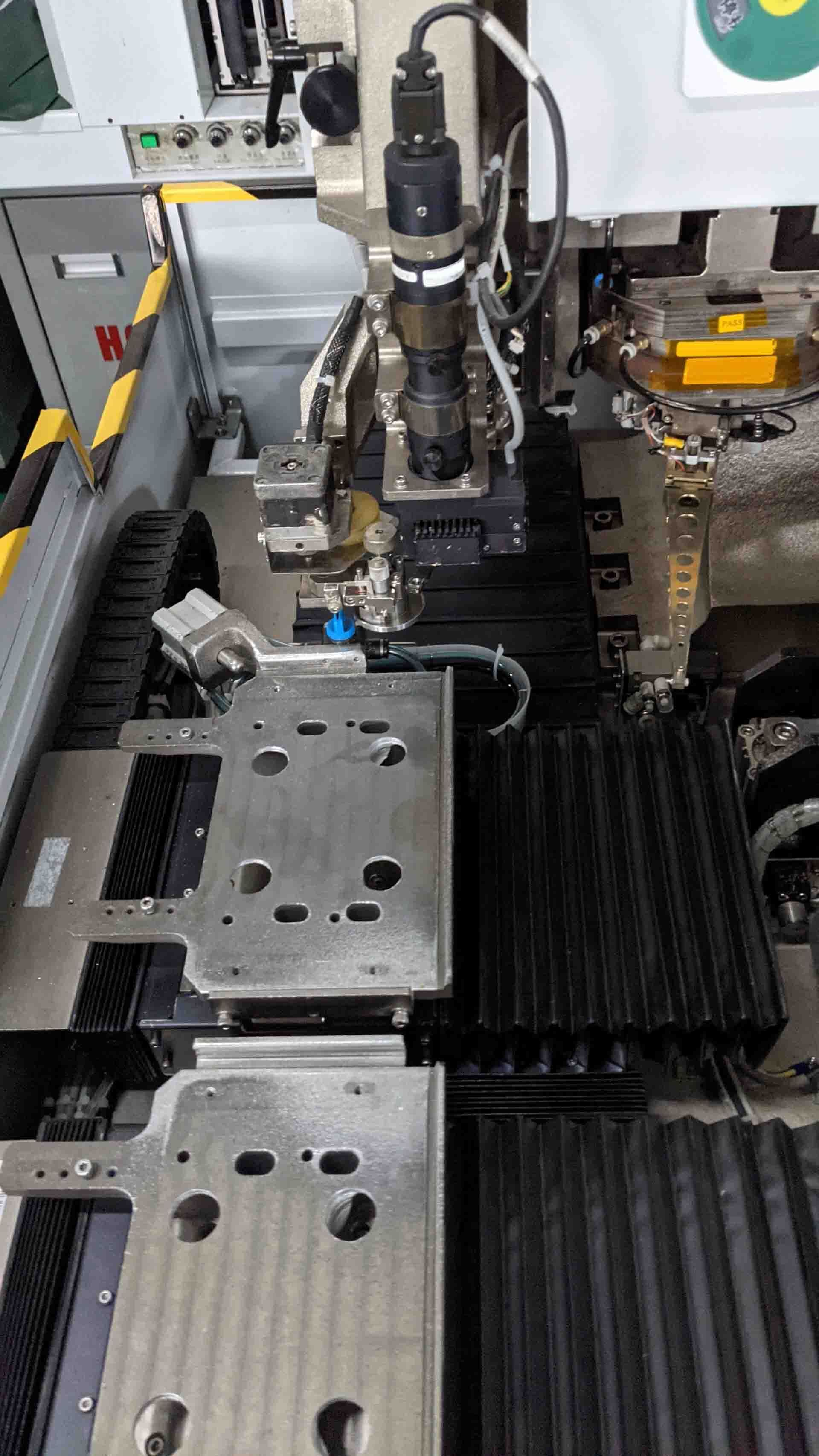

ASM AD 860M die attacher is an automated equipment for attaching flat components or round parts such as wafers, ball grid arrays (BGAs), and LCD displays. This advanced die-attachment system features a high-speed vision unit and state-of-the-art motion control for precision, accuracy and quality control. The vision machine and motion control differentiate AD 860M from all other die-attachment systems. The vision tool is used to identify any defects in the die or component being attached and adjust the parameters to ensure proper accuracy during the process. The resolution of the vision asset is 1.3µm, allowing for a high level of accuracy when placing components. In addition, the imaging model also helps identify any misalignment between the image on the die and the image on the component, which is then corrected in real time by the motion control equipment. ASM AD 860M is equipped with an advanced 9-axis robot arm and high-speed servo motors, which ensure accuracy and precision when placing components. The robot arm can be adjusted in a variety of ways in order to achieve the desired die-attachment angle. It has a maximum speed of 1000mm/sec, which adds to its effectiveness for high-volume production. In addition to its advanced vision system and motion control, AD 860M also features advanced diagnostics and quality control. The unit is fitted with a microprocessor-based controller, which monitors the process and ensures accuracy. The device also features a sophisticated temperature and pressure control machine, which guarantee consistently high-quality results. Overall, ASM AD 860M is a state-of-the-art automated die-attachment tool that is suitable for use in a variety of industries. Its advanced vision asset, motion control and high-speed servo motors enable users to achieve a high precision and accuracy when placing parts. In addition, its sophisticated temperature- and pressure-control systems ensure consistently high-quality results. All of these features make it an ideal solution for those seeking an automated model that delivers high-precision, high-quality results.

There are no reviews yet