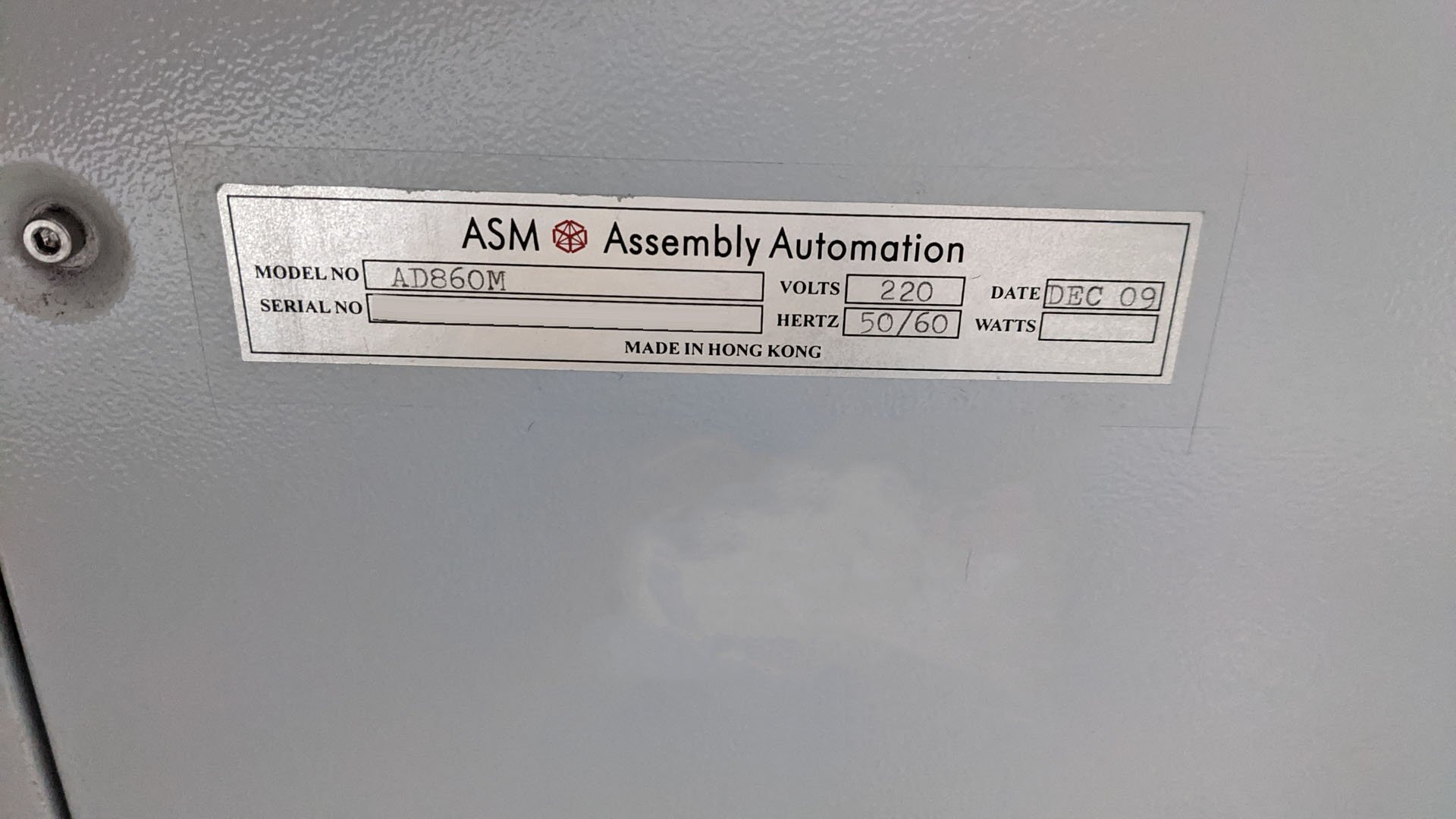

Used ASM AD 860M #9387783 for sale

URL successfully copied!

Tap to zoom

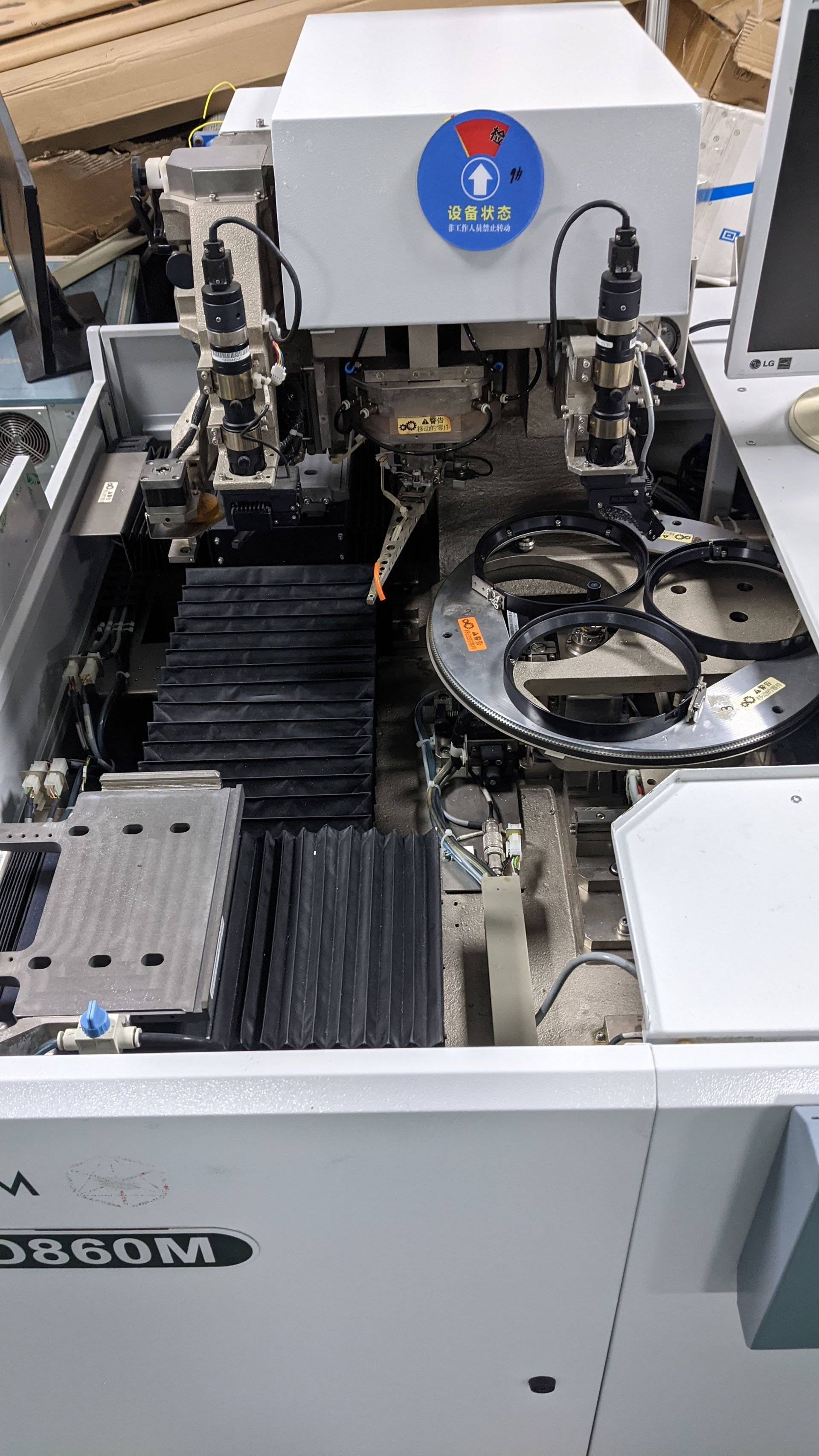

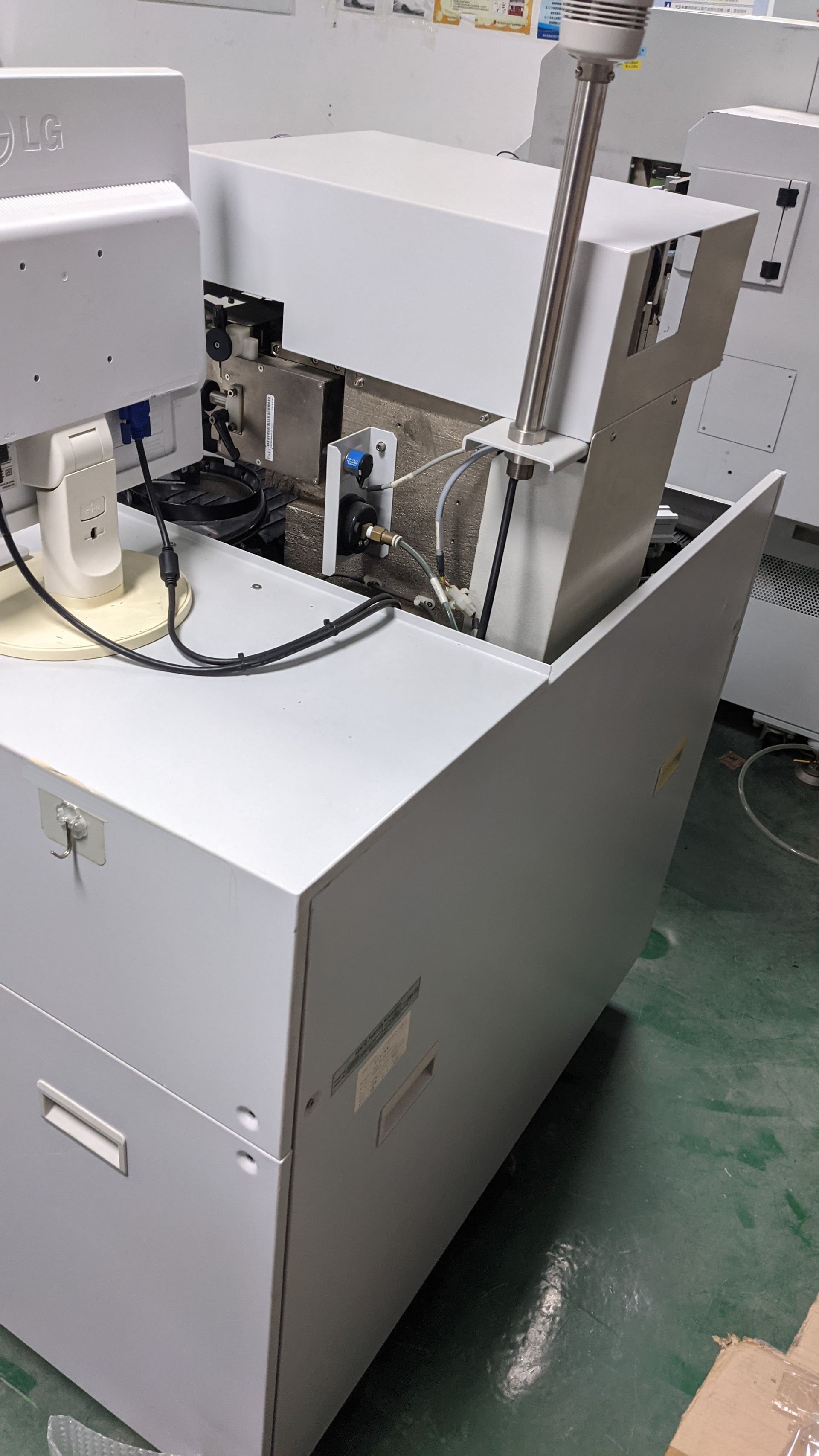

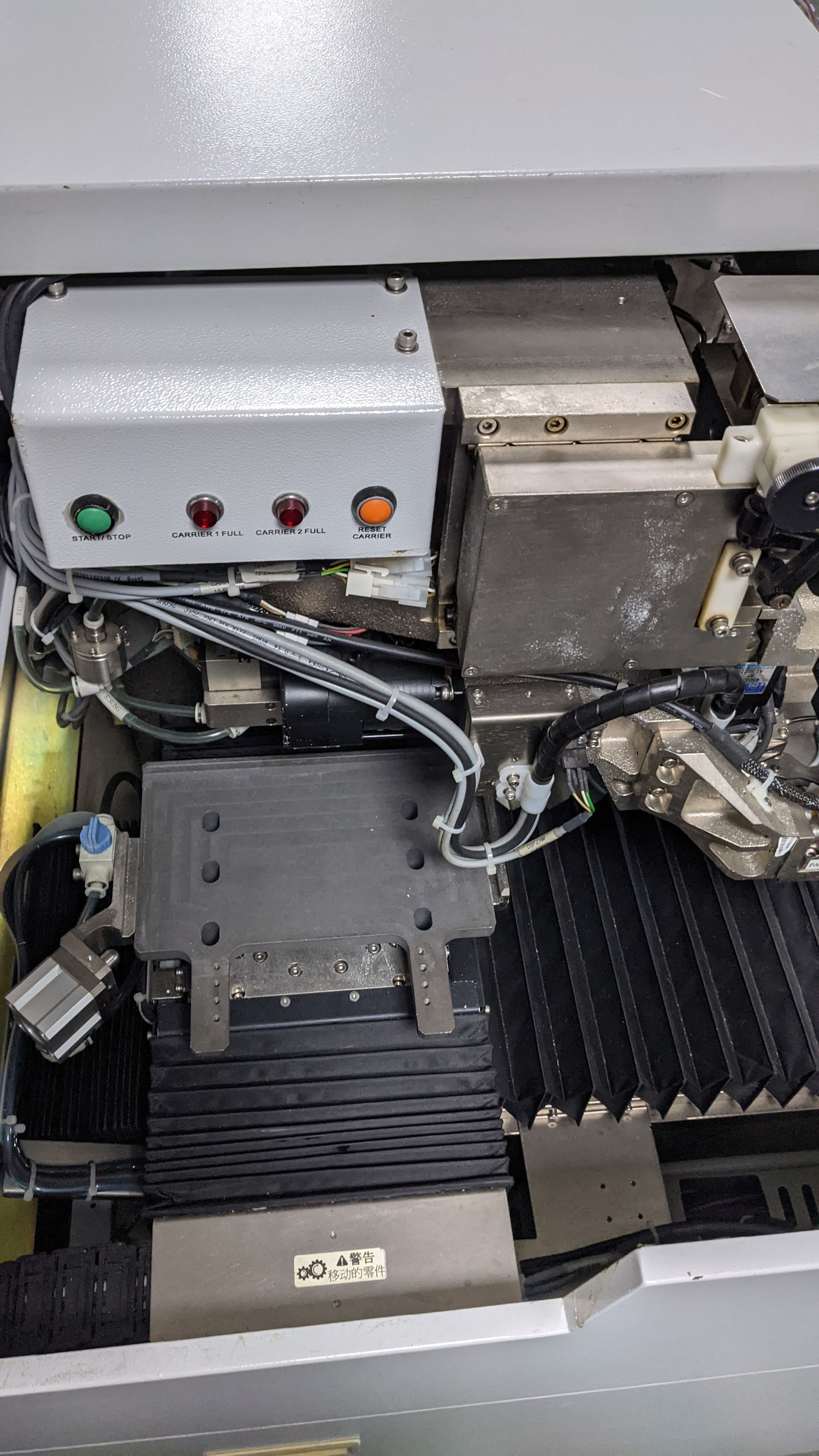

ASM AD 860M is a process die-attach machine designed and manufactured by ASM Assembly Systems. It is suitable for many different types of die attach processes, including both die attach and surface-mount attach in one single operation. The equipment has been designed to provide a precise, cost effective, and fast way of attaching die components to the substrate and other circuit board elements. AD 860M comes equipped with a touch screen user interface which allows the user to access the maximum control of the processing parameters and monitor the status of the components being attached. It also features a patented end effector design which ensures a consistent level of quality, and it is equipped with a vision system which can detect misaligned packages and adjust the process accordingly before they are attached and bonded. The Active height and die alignment unit of ASM AD 860M allows for fast and precise die and circuit board alignment. It is equipped with three cameras which give a real-time view of the part location, and also facilitate the programming and monitoring of each shot. The dual robot arm structure ensures a high degree of repeatability and accuracy, as well as permitting easy maintenance and servicing. It also features the latest thermal characteristics control technology, which ensures uniform heating and bonding across all applications. The programmable filing machine, integrated into AD 860M, stores recipes, sequences and programs for individual components. This makes it an ideal machine for mass production due to its efficient programmability. The multiple heatsink mechanism will reduce thermal instability and extend the life of the module, while a high performance motion controller works in conjunction with the vision tool to detect misalignment and provide a fast feedback loop. Overall, ASM AD 860M is an advanced die attach machine which provides accurate, cost-effective results with maximum control over the processing parameters. The multiple safety features ensure a safe operation, and the multiple-robotic arm structure allows flexibility in the processing of various substrates and components. The integrated vision asset facilitates precise alignment and uniform heating, while the programmable filing model provides efficient mass production capabilities.

There are no reviews yet