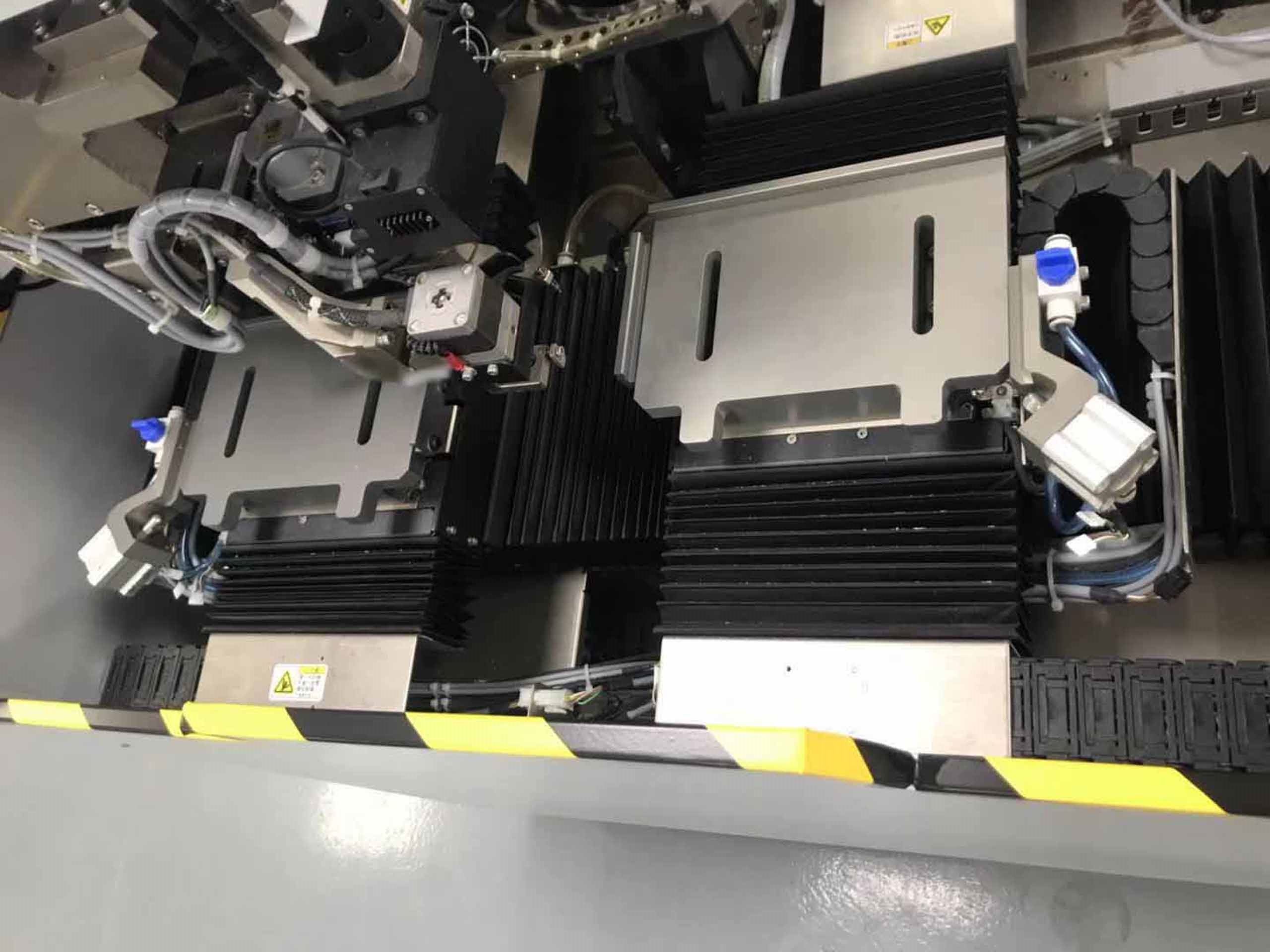

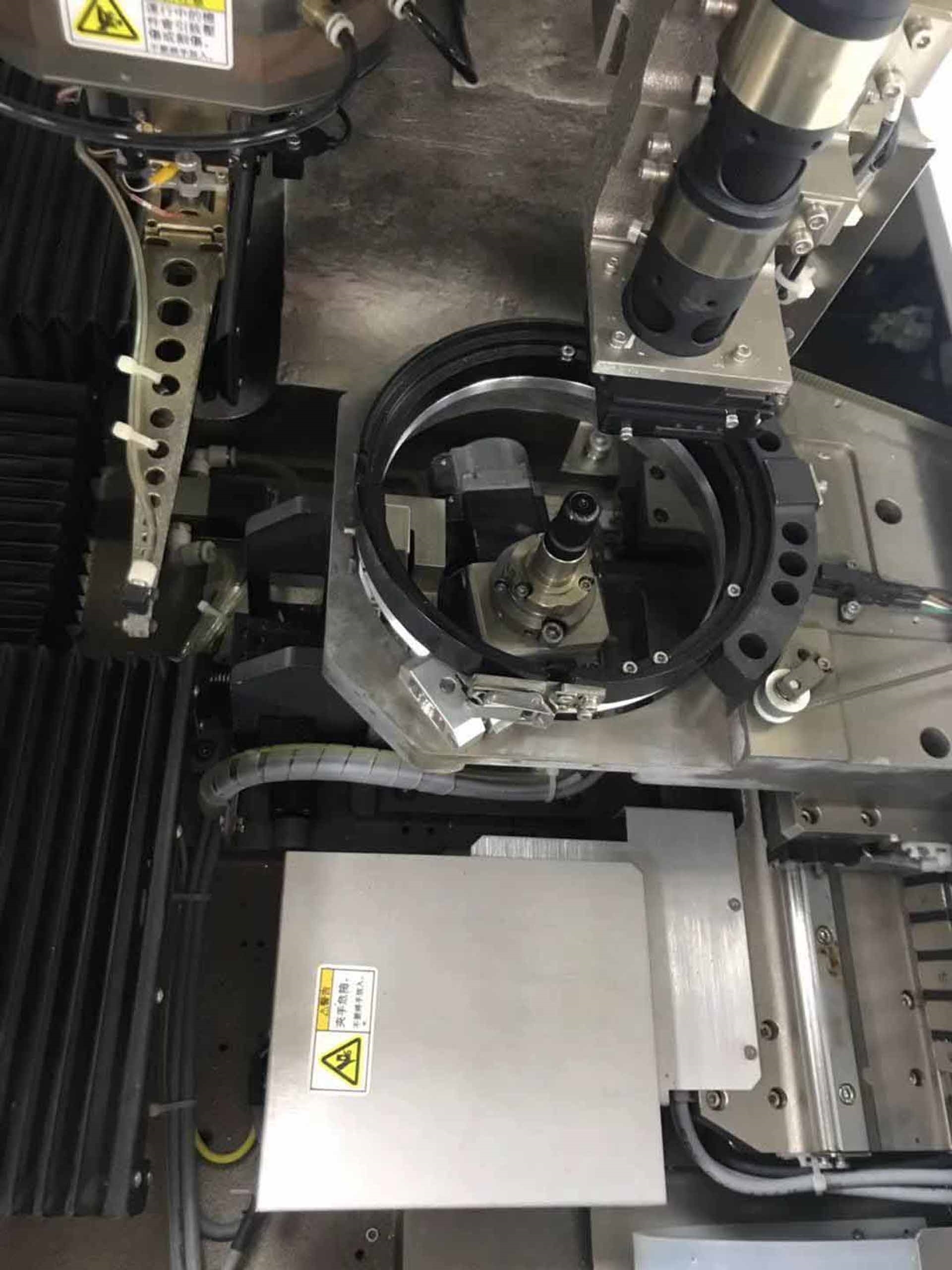

Used ASM AD 862 #9255154 for sale

URL successfully copied!

Tap to zoom

ASM AD 862 is a die attacher that is designed to automate the process of attaching a die to a substrate during the manufacture of integrated circuits. The machine uses a clamping equipment with vacuum application to fix the die onto the substrate. The die holder arm on AD 862 can be adjusted to accommodate a range of die sizes, allowing the machine to be used for a variety of devices. An included vision system is used to precisely position the die in the center of the substrate. ASM AD 862's die mounting unit works in two stages. First, a vacuum is applied to the die, whereupon it is carefully clamped onto the substrate and then the vacuum is removed. This allows the die to be transferred without any risk of damage through physical contact. The die attacher is contained in a housing with an integral laser safety machine and a closed safety circuit. This ensures that the machine will only operate when the safety tool is engaged and when the machine is in the correct alignment. The integrated safety asset is adjustable and can be set for different die sizes. AD 862 can also be used to attach the die in a two-layer formation, which is necessary for the production of advanced integrated circuits. This process requires manually selecting the upper and lower alignment points before the machine begins the attachment process. ASM AD 862 is a reliable and cost-effective die attacher that can help reduce the time and labor required in the production of integrated circuits. The precision of the machine ensures that the die will be accurately aligned and securely attached to the substrate. Finally, the integral safety model ensures that the machine is operated safely and efficiently.

There are no reviews yet