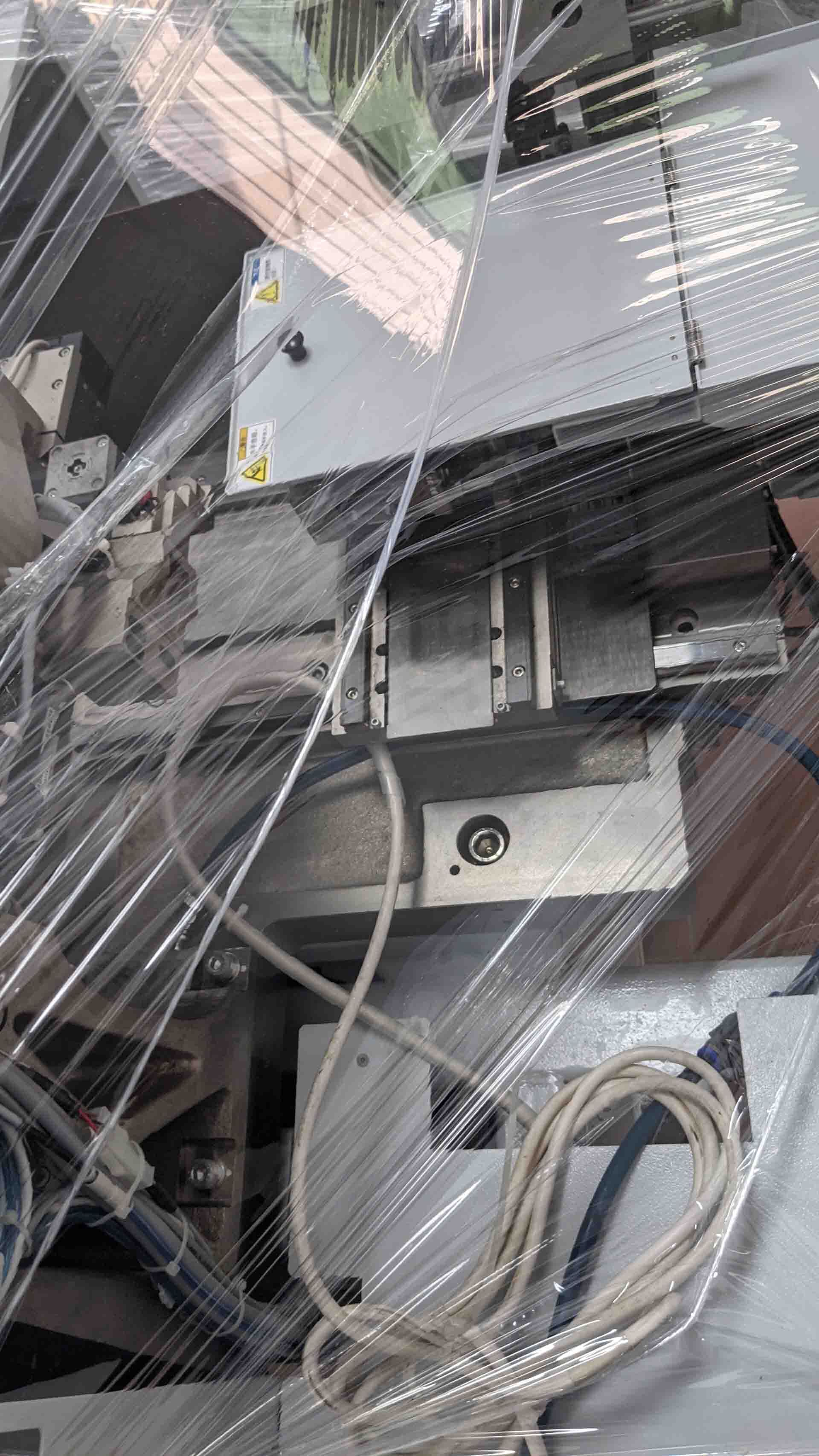

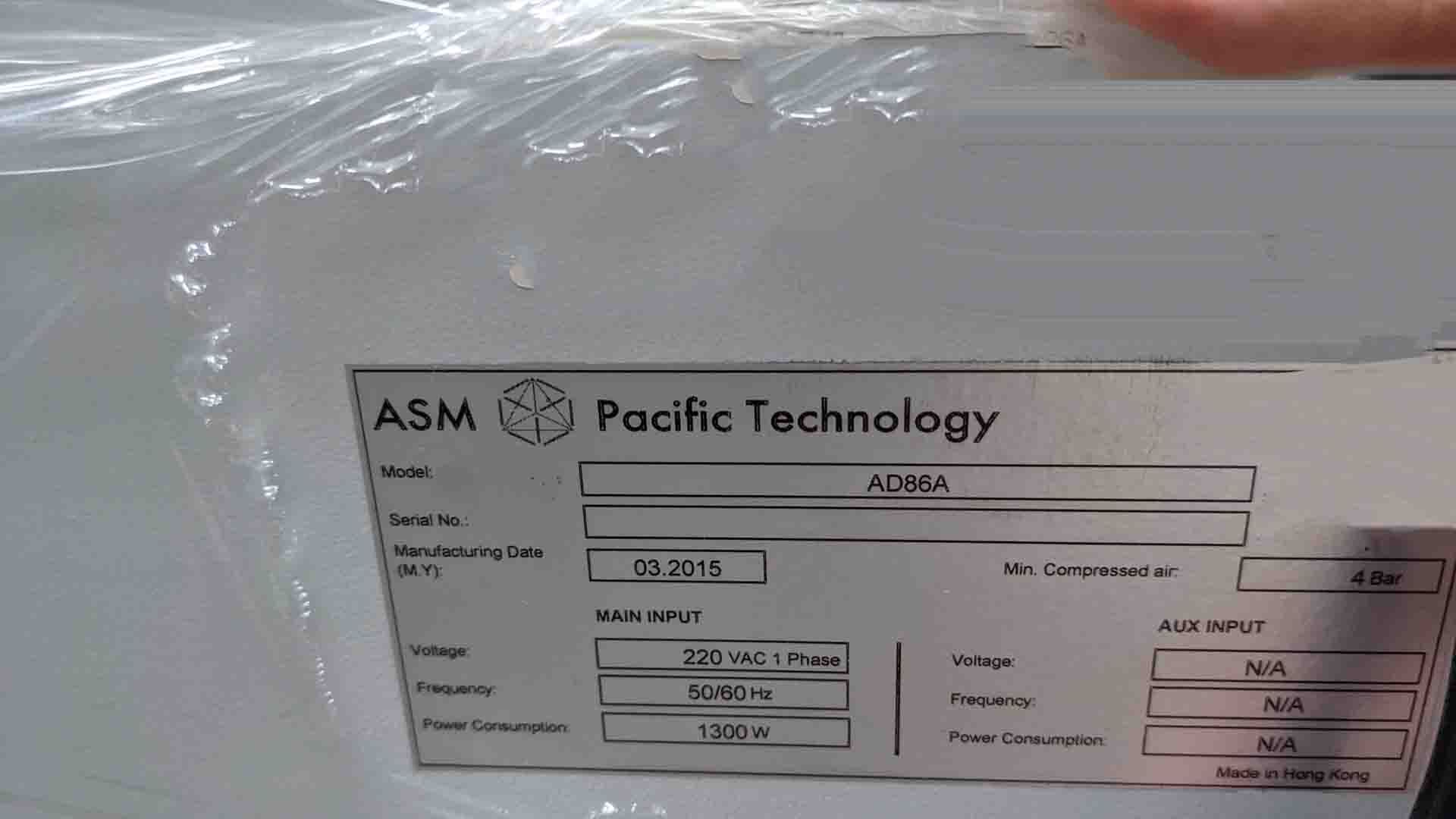

Used ASM AD 86A #9375159 for sale

URL successfully copied!

Tap to zoom

ASM AD 86A is a die attacher designed to reliably and accurately apply dies to semiconductor components. It can be used for both contact and non-contact die attach applications, making it ideal for a variety of applications. The operator interface on the device is designed for easy operation, featuring a touch screen and several menu options for access to settings and controls. The equipment also allows for recipe programming and memory storage for different tools and applications. The device also uses sensors and closed loop feedback control systems, which enable it to accurately monitor and regulate the motion of the die attachment system. This helps to ensure accurate die placement and bonding. The unit comes with various tooling options, including a vacuum tool, an epoxy dispensing tool, and a wafer clamp. In addition, the device is equipped with a fully automated die after-treatment machine, which can be used to check and verify die placement and bonding quality after each die attach operation. This tool is designed to detect any foreign material or contaminants present, and to ensure that all post-attach processes are carried out consistently and safely. AD 86A is also equipped with a process monitoring asset, which conducts self diagnostics on the die attach model to detect any potential hardware or software issues or errors. This equipment can be used to track, store, and analyze the process data in real time, allowing for better analysis and optimization. Overall, ASM AD 86A is an advanced die attacher designed to provide high accuracy and reliability for a variety of die attach applications. Its intuitive user interface, smart process monitoring system and comprehensive after-treatment unit make it a great choice for professionals that demand precision and quality.

There are no reviews yet