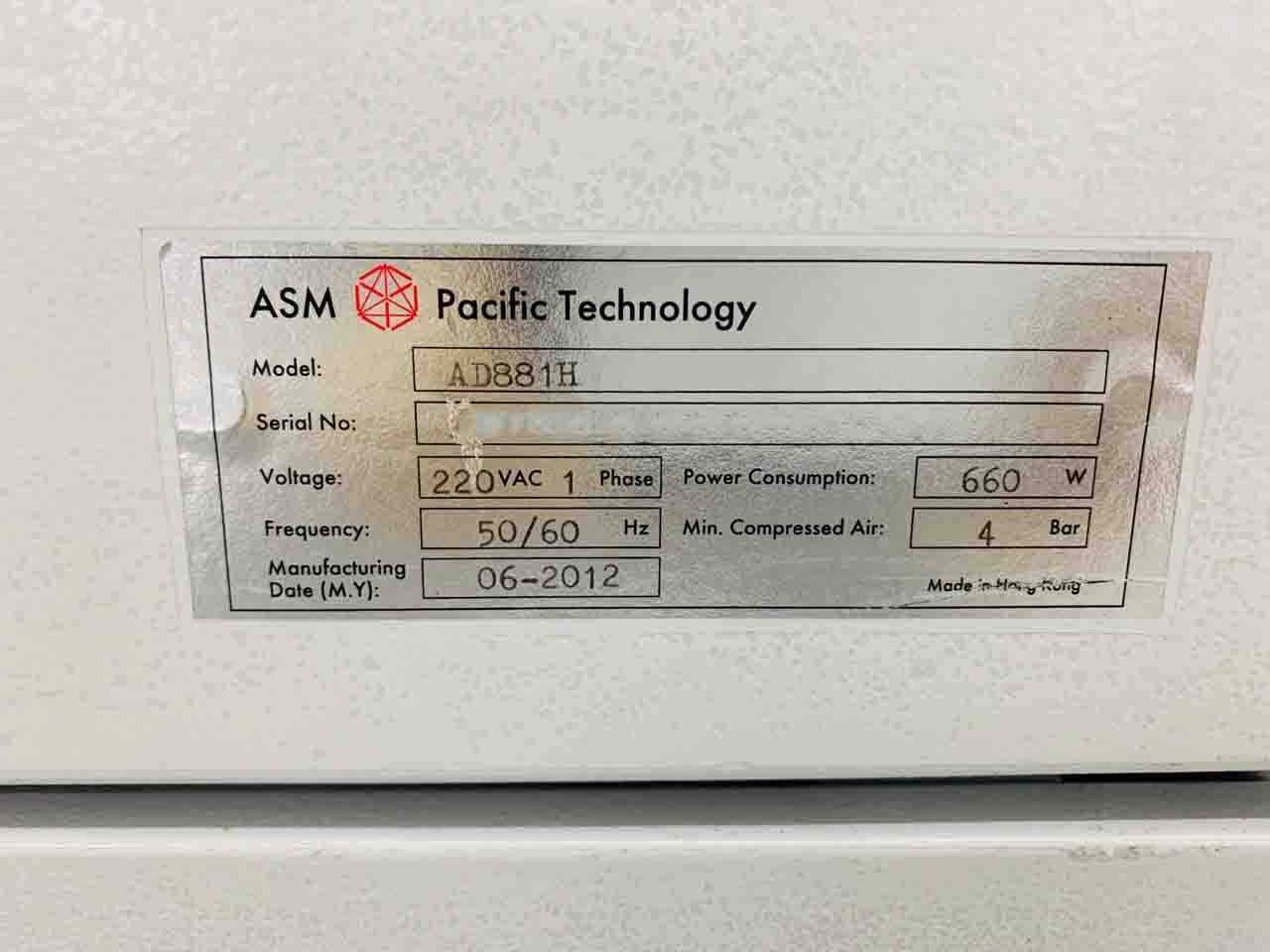

Used ASM AD 881H #9394810 for sale

URL successfully copied!

Tap to zoom

ASM 881H is a high-performance, high-volume die attacher machine used for attaching materials to printed circuit boards. This machine is designed for production lines that need high throughput and a quick turnaround of product. It is capable of attaching up to 10,000 die per hour and is equipped with an automated die handling (ADH) equipment to reduce operator fatigue. The system operates using a high-precision vision unit to align the die in the exact location. This is done through a three-axis motorized XYZ positioning machine. The positioning tool allows the die to be accurately placed on the circuit board with an accuracy of +/- 0.01mm. The asset also includes advanced algorithms for efficient alignment and placement of die. The model has advanced error sensing for detecting any misalignments or misplacements. It includes a real-time motion algorithm for tracking and compensating for any errors during the process. ASM 881H features integrated feedback capabilities for improved control of the material feeding process. It features a vibration detection equipment to identify sticking die and other problem locations. This allows for quick resolution to any problems before they can result in damage to the product. The 881H also offers a high-speed camera system for improved accuracy. The camera is used to monitor the die placement accuracy and to help adjust the placement if needed. The high-speed camera unit is also used in quality assurance, to ensure the die is properly placed with every cycle. The machine comes with an automated wafer handling machine to reduce labor costs. The wafer handling tool handles die from the die cutter to the die attacher machine. The asset is designed to reduce the risk of errors, improve production times, and reduce labor costs. ASM 881H also comes with multiple options for onboard storage. This includes options for removable storage drives, on-board Ethernet ports, and optional USB ports. The removable storage drives allow for quick and easy transfer of product designs and test data. The Ethernet ports allow for quick communication between the die attacher and other machines in the production line. And the USB ports allow for quick and easy data transfer. This die attacher is designed to provide highly-accurate and reliable automated die attachment for high-volume production lines. The model is capable of handling up to 10,000 die/hour while maintaining accurate and reliable placement. It features advanced algorithms, real-time motion tracking, integrated feedback, a high-speed camera equipment, automated wafer handling, and storage drives for quick data transfer. ASM 881H is an ideal solution for any high-volume production line that needs quick and accurate die attachment.

There are no reviews yet