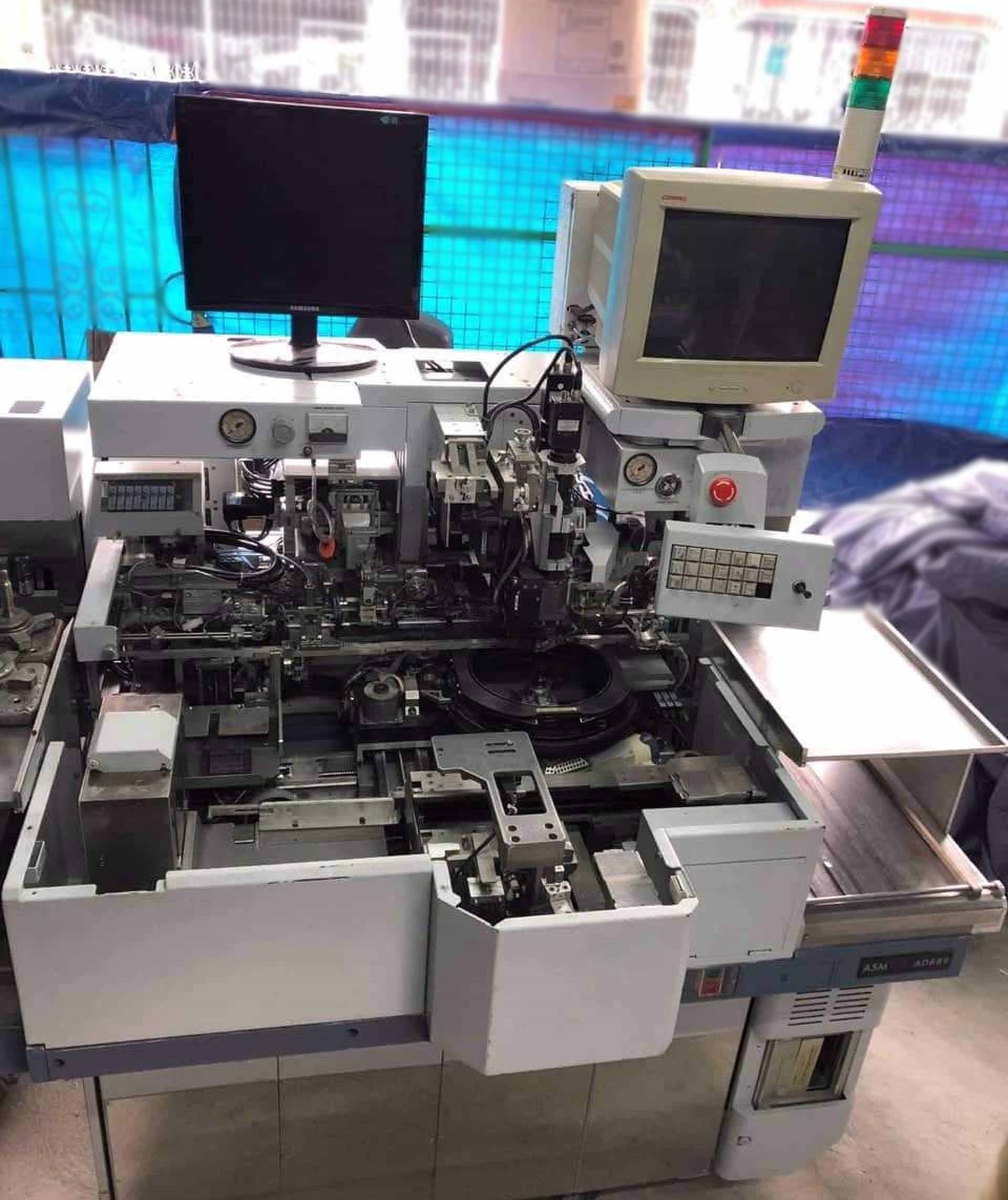

Used ASM AD 889 #9230761 for sale

URL successfully copied!

Tap to zoom

ASM AD 889 is a die attacher from ASM Automation. ASM AD889 is a versatile machine that delivers precise positioning of anionic and cationic adhesive die attach dots. This provides reliable high-speed die attach for power electronic devices. AD 889 is equipped with a industrial PC based controller and a high accuracy motion system to ensure optimal performance and accuracy. It is capable of handling a wide range of die sizes and process conditions. The die attach process is monitored with a closed-loop quality control system, which helps maintain quality assurance and lower production costs. AD889 is equipped with a high performance pump to provide precise, accurate dot placement. The pump is engineered to ensure that a constant flow rate is maintained throughout the entire dot placement cycle. This ensures consistent and reliable dot placement on every die. ASM AD 889 is equipped with a robust programmable logic controller that allows for the precise control of the die attach process. The control is user friendly and easy to program, allowing for quick set-up and optimization of the system. The machine's layout also allows quick and easy job changeover with minimal downtime. ASM AD889 is designed for flexible production and provides the capability to re-use die attach molds or tapes from a variety of vendors. This allows customers to utilize their existing molds without replacing them. In addition, AD 889 is capable of handling large PCBs of up to 12 inches in width. AD889 has built-in safety features that ensure the safety of the operator and the machinery. It is equipped with protective covers for all critical components and an e-stop button. The machine is also designed with an ergonomic environment for the operator, with a spacious, brightly lit work area. ASM AD 889 is a reliable die attacher that provides precise die attach for power electronic devices. It is capable of handling a wide range of die sizes and process conditions and ensures accurate dot placement on every die. The robust programmable logic controller and easy job changeover also allow for quick set-up and process optimization for improved production efficiency and lower costs.

There are no reviews yet