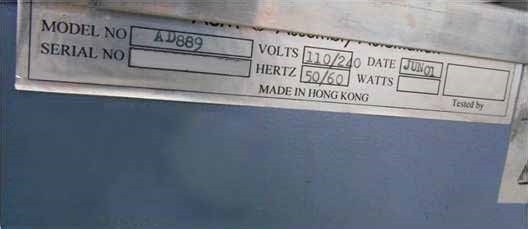

Used ASM AD 889 #9257719 for sale

URL successfully copied!

Tap to zoom

ID: 9257719

Vintage: 2001

Die bonder

SNAP CURE CO109 Oven

ASM Twin line buffer

2001 vintage.

ASM AD 889 is a high speed die attacher for chip-on-film, flip chip-on-film, and other wafer bonding applications. It is designed to provide accurate and repeatable die bonding with minimal operator intervention. The equipment is equipped with a fully automated die attach sequence and a precision die pick-up head with optional vision recognition capabilities. The die attach stage on ASM AD889 is a high speed linear motor motion system. It utilizes a microprocessor-controlled conveyor belt to move the wafer to the attach positions. The conveyor belt is adjustable to accommodate different die sizes and to optimize throughput. AD 889 also has an automatic die handling unit to ensure accurate placement and alignment of each die. The die attach head of AD889 is equipped with an eight-axis motion machine. It includes a special optical lens for precise die recognition and a die mounting guide to ensure that the die is correctly positioned for accurate die placement and bonding. The die attach head is adjustable to accommodate various substrate thicknesses and has an auto-calibration feature to enable repeatable die bonding. A heated die holder is also included to ensure uniform die temperature during bonding and to reduce substrate warping. In addition, ASM AD 889 is equipped with an optional vision tool that automatically matches die sites to corresponding bonding contacts on substrates. This asset is accurate and reliable, improving accuracy, production efficiency, and yield. ASM AD889 also includes an integrated inspection model that visually inspects each die to identify discrepancies before bonding. To sum up AD 889 is a high speed, accurate and repeatable die attach solution for chip-on-film and other flip chip bonding applications. Its automated die handling equipment, precision die pick-up head, and optional vision recognition capabilities help ensure accurate and reliable die placement and bonding, as well as increased accuracy, production efficiency, and product yield. It is the ideal solution for any die bonding application.

There are no reviews yet