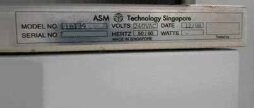

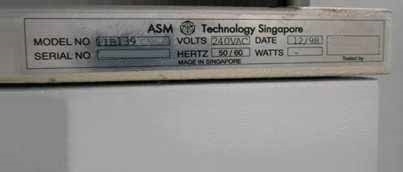

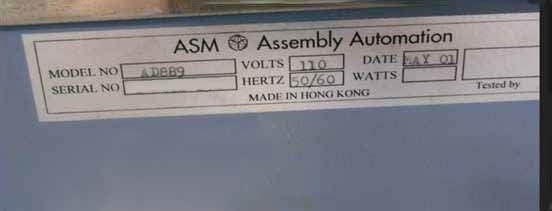

Used ASM AD 889 #9257723 for sale

URL successfully copied!

Tap to zoom

ID: 9257723

Vintage: 2001

Die bonder

SNAP CURE CO109 Oven

ASM Twin buffer

2001 vintage.

ASM AD 889 is an automated die attacher that is used to apply labels or marks to a wide variety of materials and products. It is suitable for both automated and manual material handling processes. The machine is capable of precisely and rapidly applying labels and can be used for marking most materials including surfaces, finished products, interior and exterior surfaces, and materials such as plastics, paper, textiles, and metals. ASM AD889 die attacher features a dual side-arm design, allowing for two independent production lines to be easily connected and programmable processes to be used for both lines. A standard labeling feed can be used for both lines as well, which guarantees a consistent labeling speed and delivery. It also features a Large Touch Screen HMI for quick set up and programming for recipes and other processes. The key features on AD 889 are its reliable labeling accuracy, simple operation, and efficient production. It is designed for quick setup and start up and is capable of producing consistent and precise marks even under higher volume conditions. The marking and labeling speed of AD889 can reach up to 10,000 pieces per hour and it also features adjustable dwell time and pressure ensuring that the label is accurately placed and firmly attached to the material. ASM AD 889 also can be easily integrated with a variety of production lines and can accept outputs from a wide range of other pieces of equipment. It can, for example, be paired with, visual inspection equipment, labeling machines, laser scanning equipment, and other processes and devices used in automated production lines. The machine is also very easy to maintain, as it requires minimal routine maintenance and is simple to clean. In conclusion, ASM AD889 is an efficient and reliable die attacher. It is designed for quick setup and start up and is capable of producing consistent and precise marks even under higher volume conditions. It can also be paired with a variety of production lines and easily integrated with other devices and processes. Finally, it requires minimal maintenance and is easy to clean, making it a great choice for any production line.

There are no reviews yet