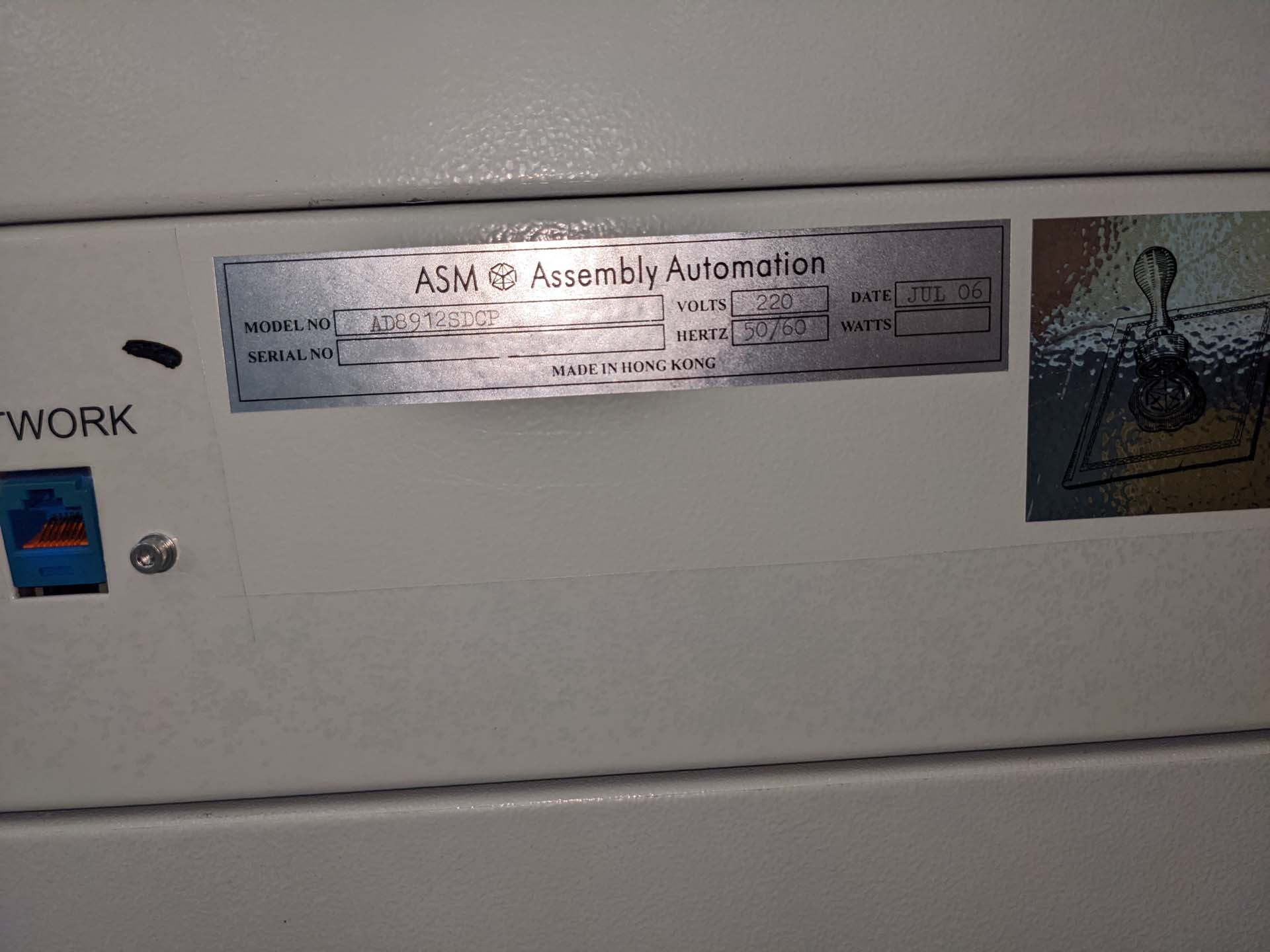

Used ASM AD 8912 SDCP #293662002 for sale

URL successfully copied!

Tap to zoom

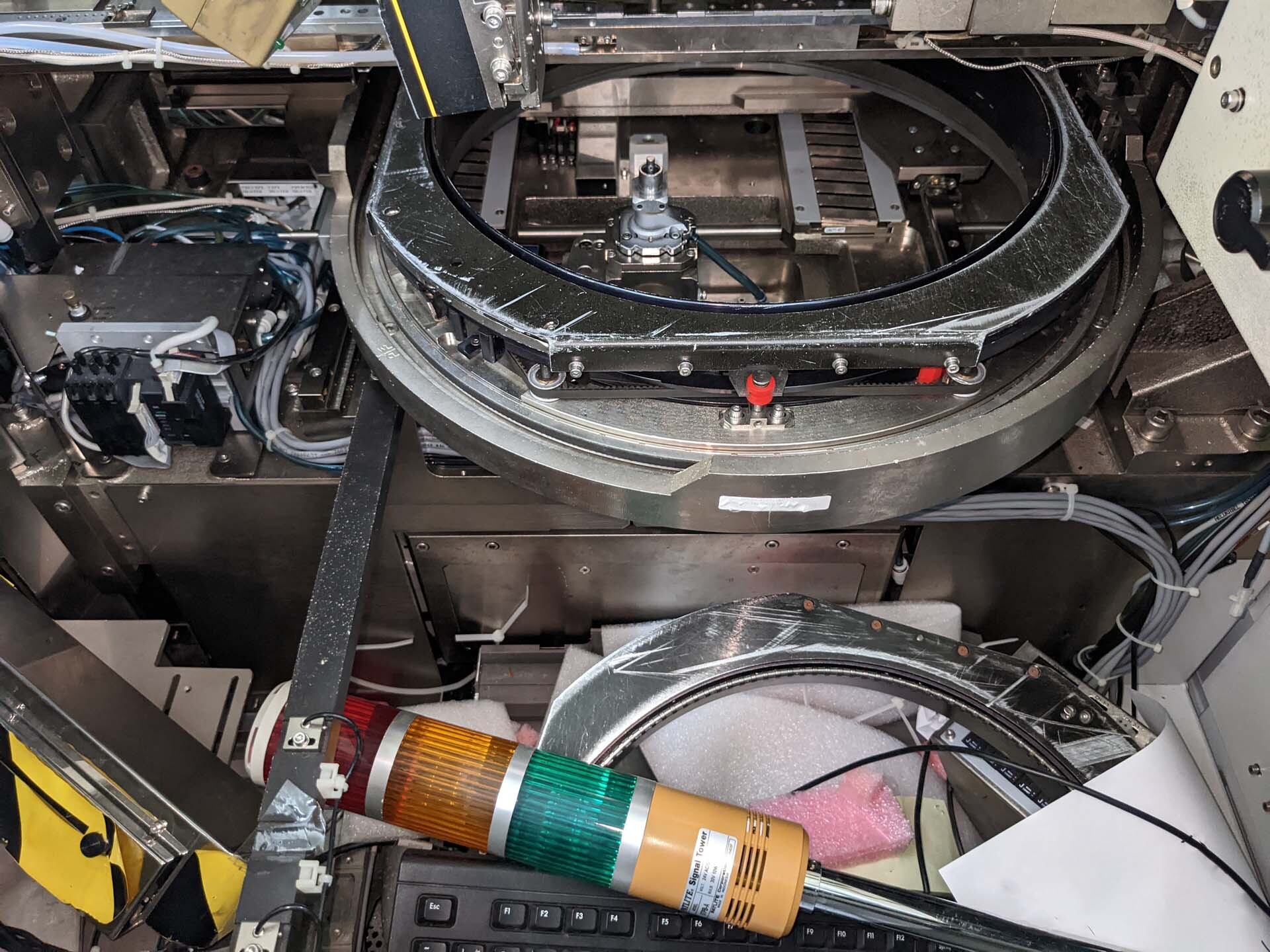

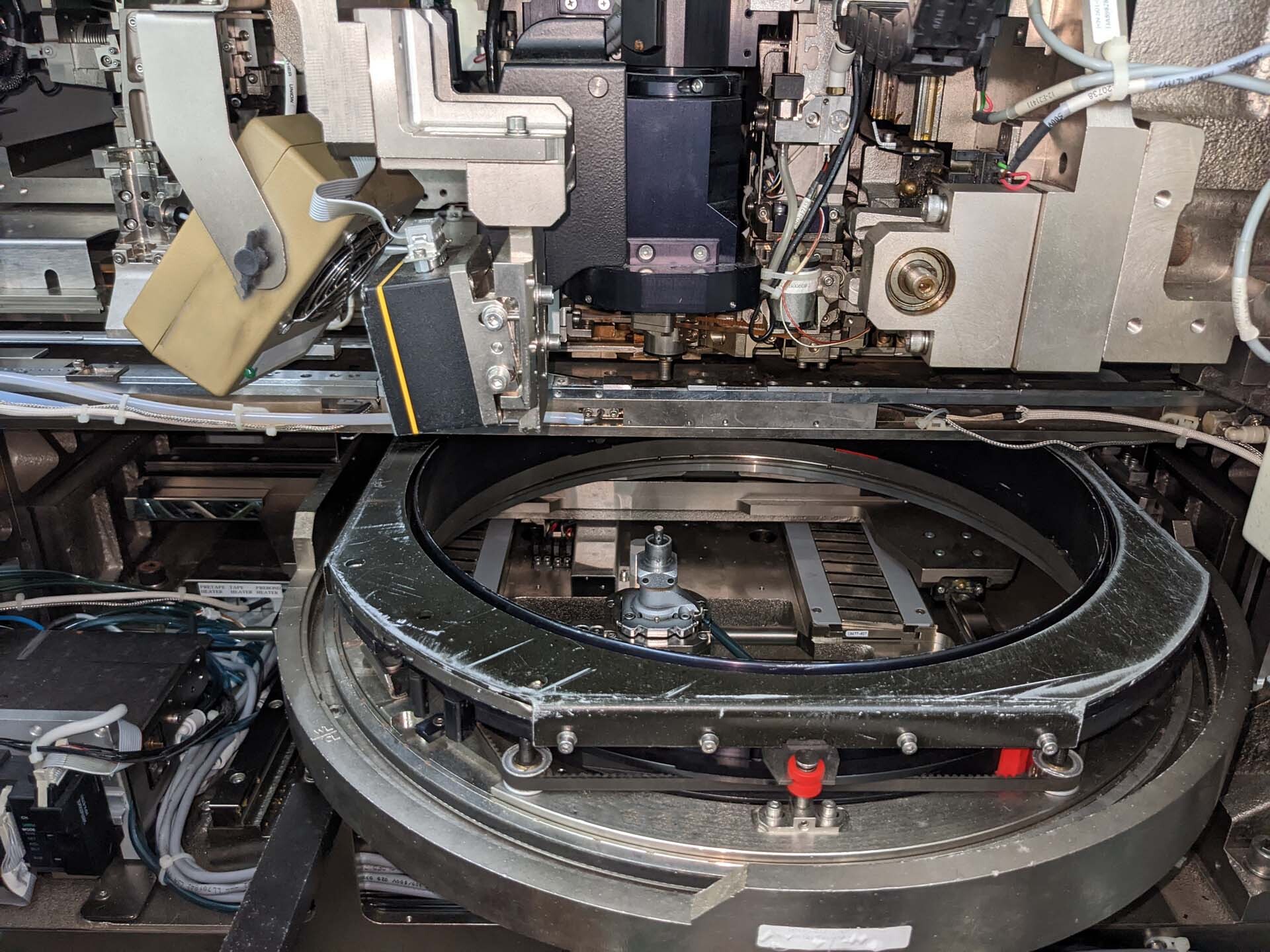

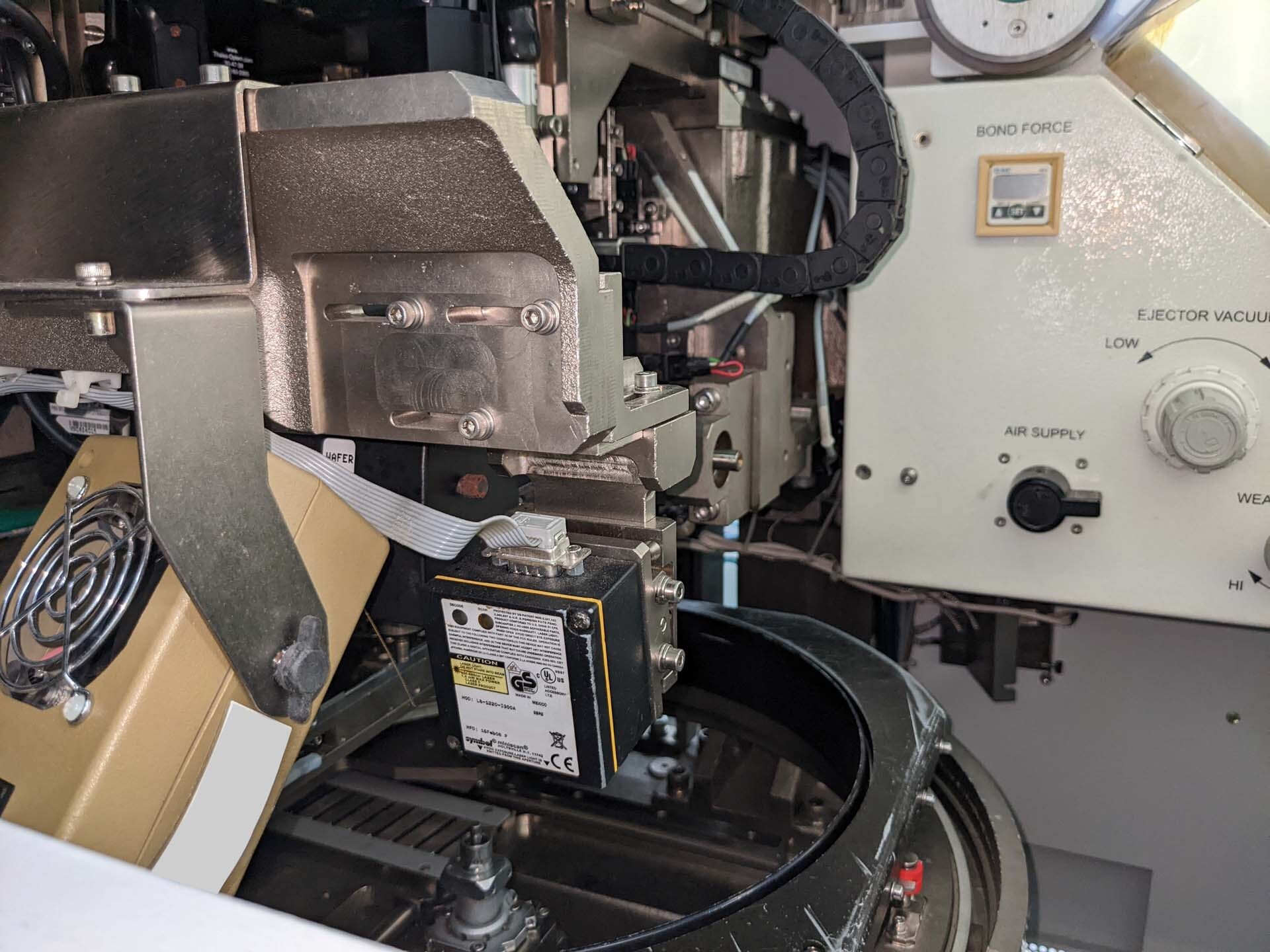

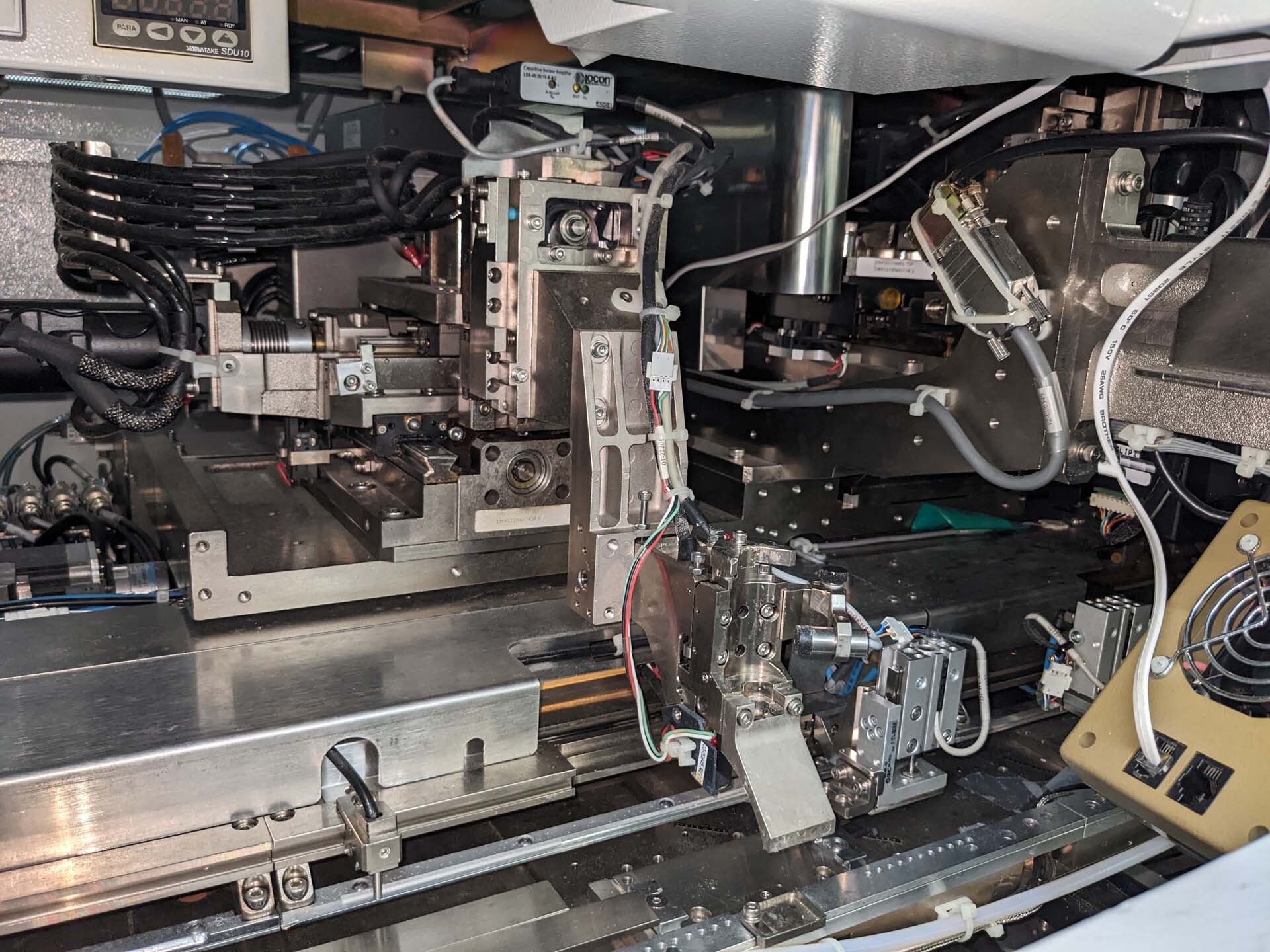

ASM AD 8912 SDCP is a die attach machine which is designed for high rate volume production of hermetic components. It is a fully automated die attach equipment that makes it possible to quickly and reliably attach miniature semiconductor chips and devices to their substrates. The die attach process is carefully monitored and controlled using the latest in advanced process control technology. AD 8912 SDCP uses a robotic arm to pick up a pre-loaded die from a tray and accurately place it onto the substrate, where it is affixed using a thermal bonding technique. This high-speed process allows for rapid turnaround times and economy of scale production. The system also features an automated tool management unit (ATM) for efficient loading and unloading. The machine is equipped with a high-resolution vision inspection machine which helps to detect design or material flaws. This is followed by a highly advanced software tool with a vast library of settings and recipes to quickly and easily adjust the asset's parameters and settings depending on various requirements of a given production run. ASM AD 8912 SDCP is capable of delivering a wide variety of die attach materials such as solder, epoxy, and conductive plastics. It also has the capability to apply flux to substrates prior to die attach process, which helps ensure stable adhesion and prevent thermal damage to semiconductor parts. The machine is designed with low maintenance requirements, so it is ideal for high-volume production with sustained quality. It features fast programming, parallel operation, custom handling, minimal downtime for maintenance, good batch repeatability, and long time stability. In conclusion, AD 8912 SDCP is a reliable and cost-effective die attach machine designed for high rate volume production. It features advanced process control technology, automated tool management model, high-resolution vision inspection equipment, and a wide variety of die attach materials. It has low maintenance requirements and delivers consistent and repeatable results for a range of applications.

There are no reviews yet