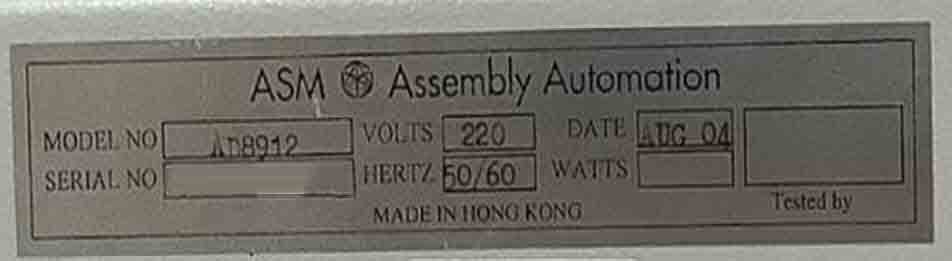

Used ASM AD 8912 #293609450 for sale

URL successfully copied!

Tap to zoom

ID: 293609450

Wafer Size: 12"

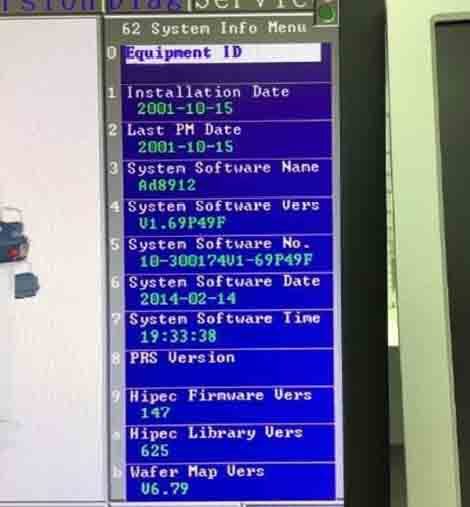

Vintage: 2004

Die bonders, 12"

XY Table travel: 334 mm x 334 mm

Die size: 10 mm x 10 mm to 1000 mm x 1000 mm

Die placement accuracy (XY): 8.38 µm

Epoxy fillet height: <2/3 of die thickness

Work holder indexer (Linera motor)

(2) Pick / Bond heads (Linera motor)

Ejector

Wafer handler

Vision system

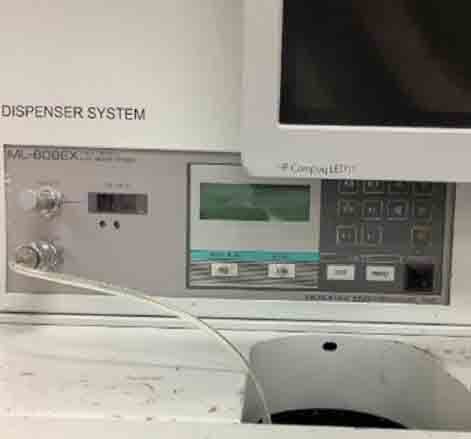

MUSASHI Pumps dispenser

Epoxy writer: Disposal nozzle

2004 vintage.

ASM AD 8912 is a state-of-the-art die attach equipment designed specifically to increase efficiency in IC assembly processes. The system is designed to accommodate both die size and package substrates, making it ideal for multi-layer circuit applications. The machine is equipped with a novel touch screen controller which allows for easy programing and operation of the unit. ASM AD8912 is capable of processing up to 14 parts per minute, making it one of the fastest die-attach systems available. AD 8912 is equipped with a single-axis, three-axis and universal die attach positions for enhanced flexibility. This direct-drive and gravity-flow delivery machine ensures constant speed, accuracy and repeatability when placing individual dies and assembled circuits onto the package substrate. An optional automated dispensing tool allows for the automated dispensing and placement of individual dies which increases speed, accuracy, repeatability and cost-efficiency. In addition, the machine features a bonded lid section which can be used to cover the package substrates after die placement. The lid-covering asset is capable of reaching temperatures up to470°C, resulting in optimized adhesion of packages. A patented die-to-die double heater heats both the die and package substrates simultaneously and evenly, reducing cycle time and increasing process accuracy. AD8912 is designed with multiple safety features, including a temperature monitoring model which ensures that the correct temperature is reached before heat is applied. The machine is also equipped with a robust vision equipment that reduces the risk of defects caused by mis-alignment and helps to ensure the highest quality process control. Overall, ASM AD 8912 is an efficient, cost-effective die attach system that is ideal for multi-layer circuit applications. With its high speed, accuracy and repeatability, it is a great choice for high-volume bonding tasks.

There are no reviews yet