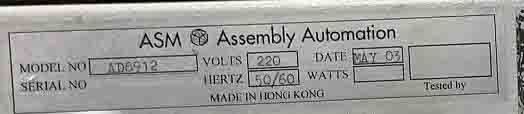

Used ASM AD 8912 #9408544 for sale

URL successfully copied!

Tap to zoom

ID: 9408544

Wafer Size: 12"

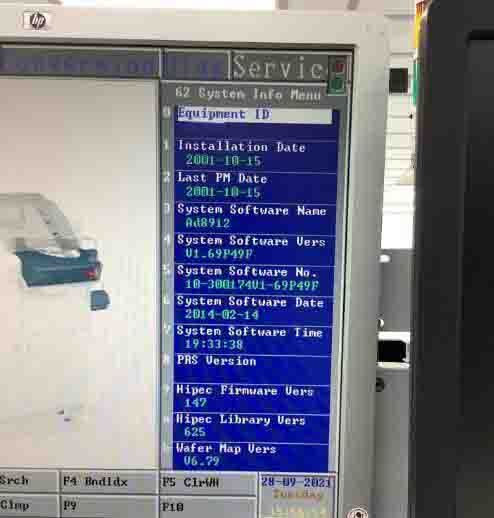

Vintage: 2003

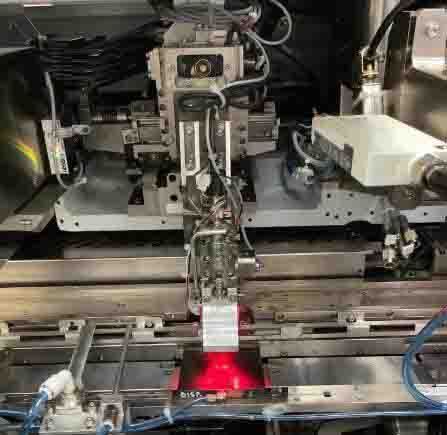

Die bonder, 12"

Wafer X, Y table travel (13" x 13") 334 x 334 mm

Die size (10 x 10 mil to 1000 x 1000 mil)

Die placement accuracy X, Y (0.38 mil) 8.38 um

Epoxy fillet height (< 2/3 Die thickness)

BLT Typically: 1 0.2 mil (Material dependent)

Work holder indexer (Linear motor)

(2) Pick / Bond heads (Linear Motor)

Ejector system

Wafer handling system

Vision system

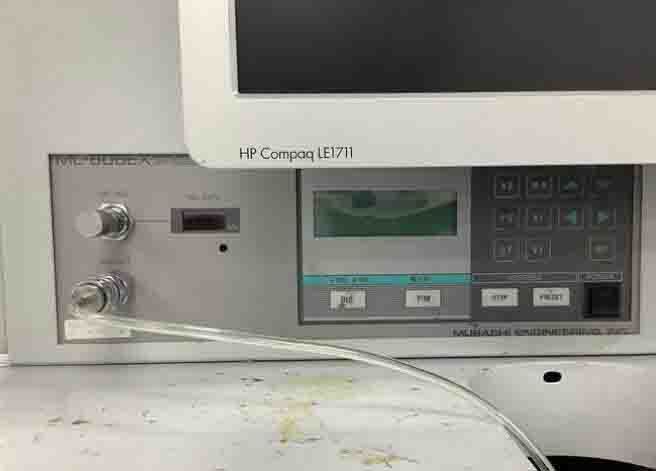

Dispensing system (MUSASHI Pump)

Epoxy writer system (Disposal nozzle)

2003 vintage.

ASM AD 8912 is a high-performance die attacher designed for the highest accuracy and reliability. It is used to easily attach products and components to a work surface. The die attacher is powered by a high-speed servo motor, which runs quietly and has a long service life. The machine has a large operational speed range, from 0.1 to 1500rpm, and the servo drive system is capable of controlling the movement of each individual die. In addition, the machine features an extended working length and improved protection against dust and moisture. The die attacher is equipped with a camera for scanning, positioning, detecting defects and relocating component positions for accurate and efficient attaching. It also features a worktable with a built-in cooling channel and a built-in lighting system that provides bright, even illumination for all working positions. The die attacher is also equipped with a multi-groove drive component, which helps to ensure an optimal performance. To ensure a smooth and reliable operation, the die attacher is equipped with a linear guide rail with rollers and an automatic locking mechanism. This allows for the accurate positioning of the dies and the secure attachment of components. Furthermore, the positioning system is equipped with a motion detection software that helps to detect any exceeding of limits and makes adjustments accordingly to prevent overstretching or breaking of the die attachments. The die attacher also features an adjustable vacuum level, which can be tailored to meet the needs of the application. This enables the machine to securely and reliably attach components and products to a work station or surface with a pre-defined vacuum setting. Overall, ASM AD8912 die attacher is an efficient and comprehensive solution for attaching components and products to surfaces. Its high-speed motor, extended working length and adjustable vacuum levels, along with its automated scanning, positioning and defect detection facility, make it an ideal machine for a wide range of applications.

There are no reviews yet