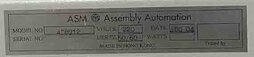

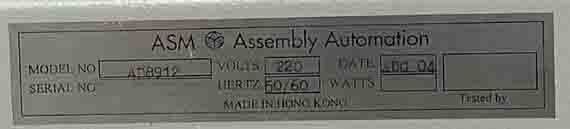

Used ASM AD 8912 #9408552 for sale

URL successfully copied!

Tap to zoom

ID: 9408552

Wafer Size: 12"

Vintage: 2004

Die bonder, 12"

Wafer X, Y table travel (13" x 13") 334 x 334 mm

Die size (10 x 10 mil to 1000 x 1000 mil)

Die placement accuracy X, Y (0.38 mil) 8.38 um

Epoxy fillet height (< 2/3 of die thickness)

BLT Typically: 1 0.2 mil (Material dependent)

Work holder indexer (Linear motor)

(2) Pick / Bond heads (Linear motor)

Ejector system

Wafer handling system

Vision system

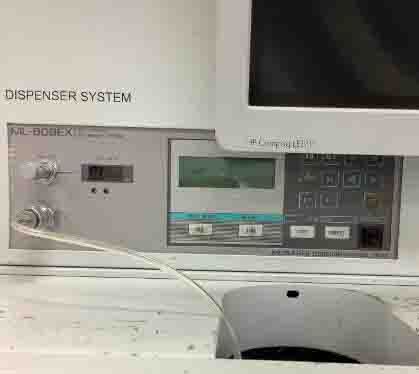

Dispensing system (MUSASHI Pump)

Epoxy writer system (Disposal nozzle)

2004 vintage.

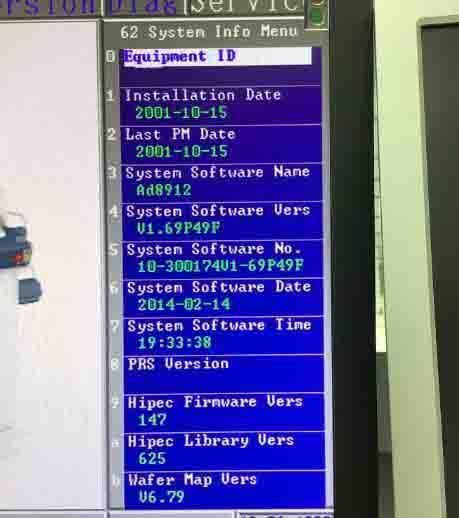

ASM AD 8912 Die Attacher is an advanced, automated die attacher designed for high-volume die-attaching needs. It is designed for high-speed production and offers an efficient, error-free means of attaching dies. ASM AD8912 features servo drive technology to control its production process and achieve outstanding accuracy and repeatability. The machine has four servo motors, two horizontal and two vertical, to manage each of the stages of the die-attaching process. This ensures that the die is accurately aligned when it is attached to the substrate. AD 8912 has a wide range of die sizes that it can handle, ranging from 1/2 inch to 6 inches in diameter, and the dies can be attached to a variety of substrates, such as boards and plastic cards. The machine has an oscillating arm system to evenly spread the adhesive film over the substrates and the dies. The system then uses an ionizing beam to evaporate the adhesive film and attach the dies to the substrate. The precision rollers allow the machine to precisely control the amount of evaporation and the exact placement of the die. The machine incorporates two digital displays that provide the user with important information about the die-attaching process. This enables users to monitor the process and verify that it is running smoothly. AD8912 features several safety features, including an emergency stop button and an audible warning system. ASM AD 8912 Die Attacher is an efficient and accurate way to attach dies with high-speed production capabilities. It has been designed to ensure accuracy and repeatability, while its safety features provide peace of mind and its digital displays provide critical information to its users.

There are no reviews yet