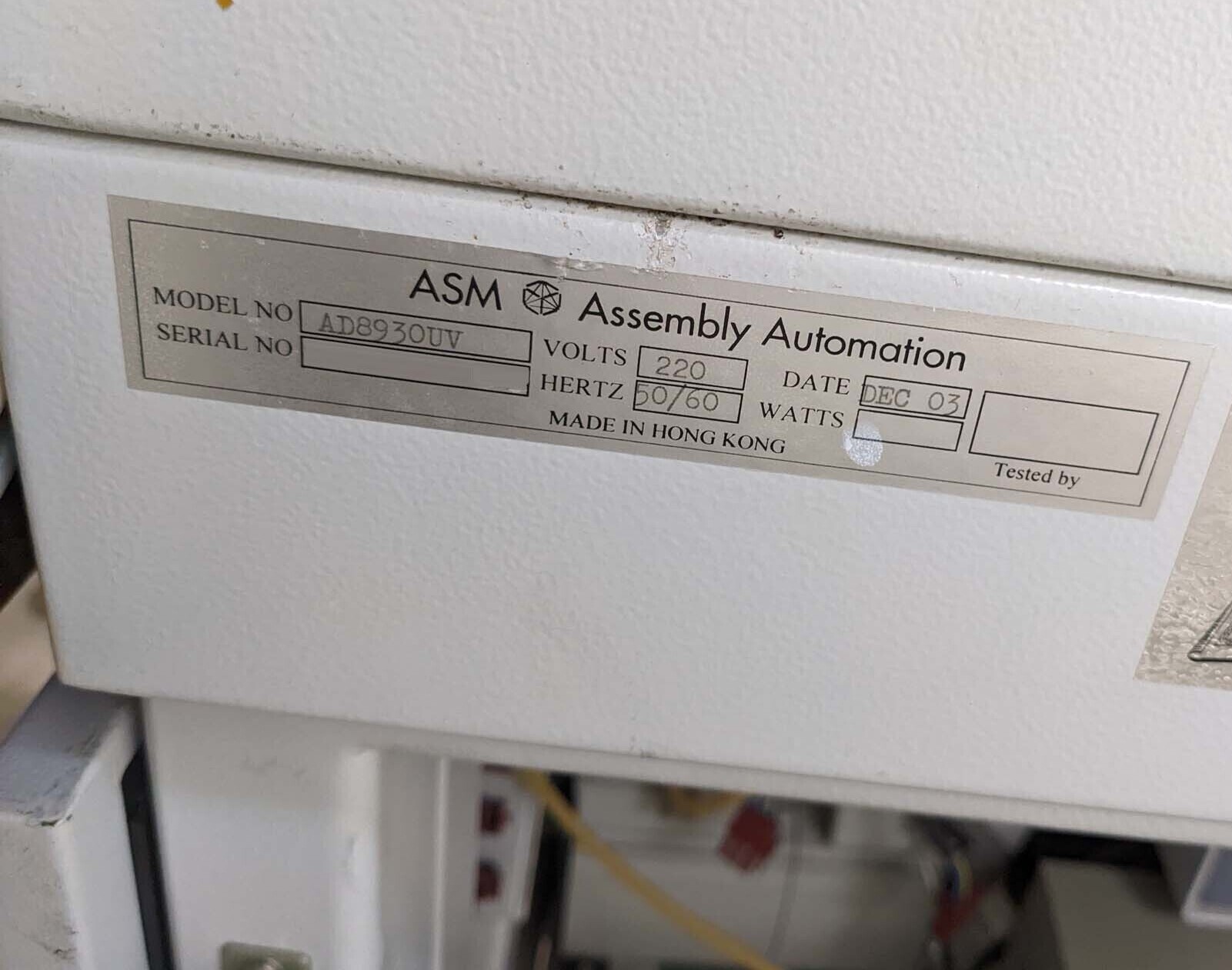

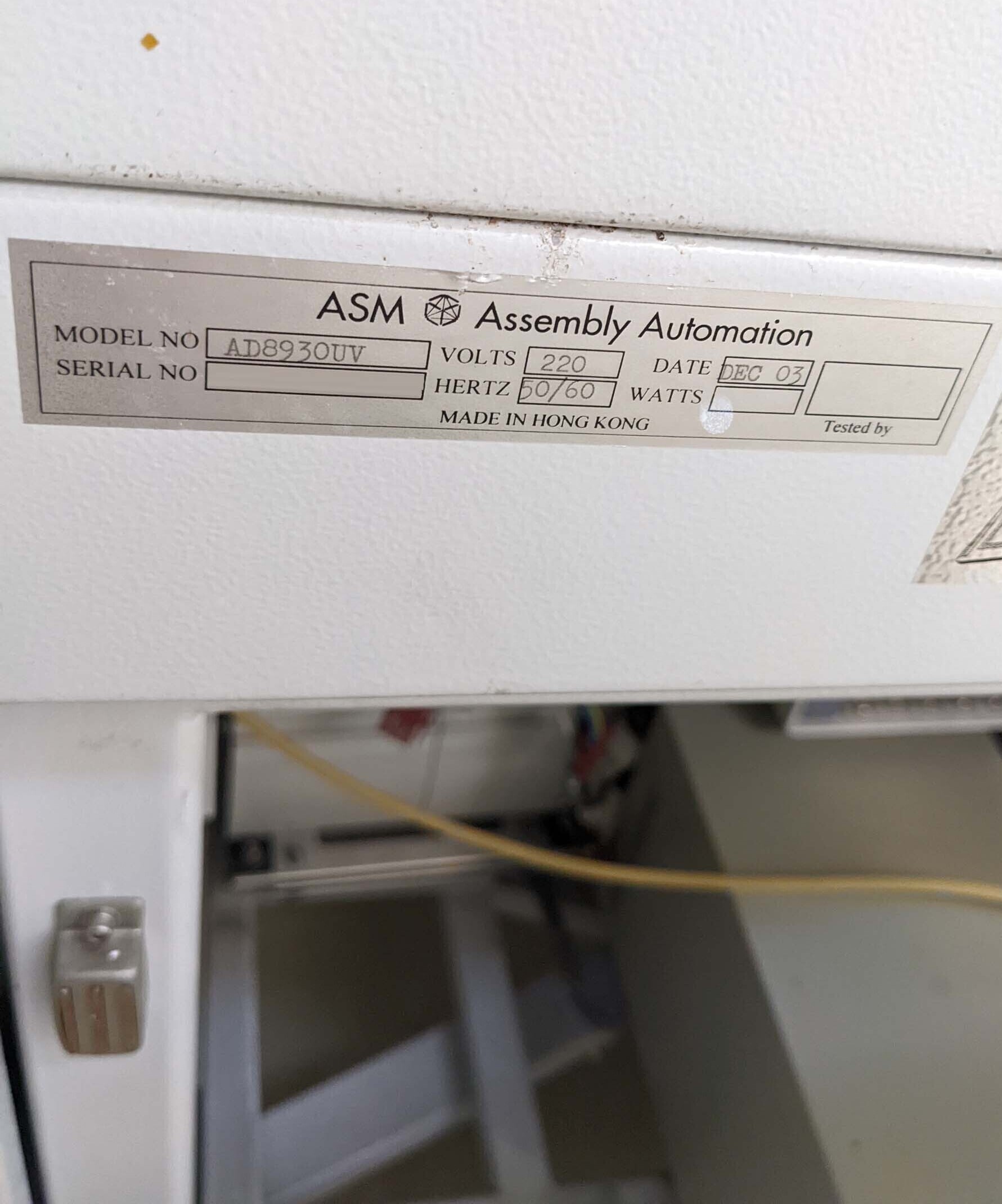

Used ASM AD 8930UV #293634990 for sale

URL successfully copied!

Tap to zoom

ASM AD 8930UV Die Attacher is a fully automated die bonder that is optimized for high throughput and unparalleled quality. It is designed to be used in the most demanding packaging environments, such as flip chip, Wafer Level CSP, and other highly specialized die attach processes. Its features include a 6-sided die attach, automated die sorting, precision placement and position verification, and temperature monitoring. The 6-sided die attach is designed to provide superior adhesion, reliability, and throughout. This feature enables the attachment of virtually any type of die or wafer, regardless of size or shape. Automated die sorting capability is provided to ensure the highest yield of quality dies among the package components. The precision placement and position verification ensure that all parts are perfectly aligned and in their designated locations. Temperature monitoring offers an additional layer of assurance that all parts are stable at their optimum operating temperature. AD 8930UV also comes with a dual bonding head, allowing for a smooth and accurate transfer of heat from the bonder to the package during the die attach process. Its high repeatability and accuracy also provide excellent yields during all runs. Additionally, the die bonder is equipped with several safety measures designed to protect against and detect any potential safety risks associated with its operation. ASM AD 8930UV is designed to be used in tandem with the company's software solutions and dedicated maintenance packages, offering high speed and low downtime in complex high-density assemblies. For best results, the user should use the automated height control, which is specifically tuned and optimized to the die bonding process. As an added benefit, this die bonder also includes an advanced vision system that allows for machine vision lamination and online vision inspection. Overall, AD 8930UV Die Attacher is a highly advanced and reliable die bonder that has been specifically designed to address the needs of the highly specialized die attach processes used in the most demanding packaging environments. Its automated die sorting and temperature monitoring capabilities ensure that all parts are properly aligned and remain stable and safe at their optimum operating temperature. Its high repeatability and accuracy guarantee excellent yields, while its vision system allows for quick and accurate vision lamination and inspection. With its safety systems in place, users are sure to achieve reliable and consistent results even in the most complex high-density assembly jobs.

There are no reviews yet