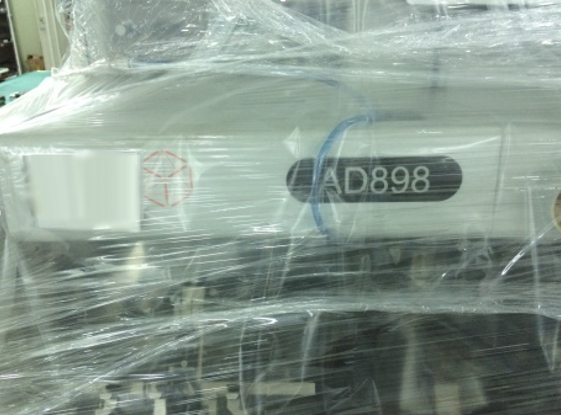

Used ASM AD 898 #9099403 for sale

URL successfully copied!

Tap to zoom

ASM 898 die attacher is a computer-controlled robotic machine purpose-built to automate the process of attaching metal dies to a variety of substrates. It offers precise, repeatable and efficient production of parts and components, even with multiple and complex dies. The machine is equipped with two robot arms that perform parallel and simultaneous operations, allowing it to complete projects with both complex and simple shapes quickly. The machine is designed for the automatic and reliable mounting of metal dies onto a variety of substrates, such as plastic, metal, and fibrous material. The dies are placed on the die holders attached to the substrate via mechanical, adhesive or thermal bonding process. The machine is able to accurately detect and align the dies, resulting in a precision placement of the dies. It features a powerful vision system that is able to detect and verify the correct alignment of all parts and is capable of detecting possible misalignment in order to make corrections directly. ASM 898 die attacher has a working speed of up to one dedicate per second. Its flexibility in programming and adjustment, as well as its ability to analyze the data of each executed production cycle during the process, makes it an ideal solution for the fast and highly precise production of components. It allows the user to easily program customized and repeatable attach cycles for each size or type of die found in a production run, all with the help of an intuitive and visual programming interface, thereby reducing setup time and increasing the production efficiency. For manual punching and assembly operations, a pneumatically operated die plate is provided with individual actuators for each die. The die plate mounting holes, feeder location and actuator pins are automatically adjusted and verified using the machine's vision system, allowing the user to easily switch between dies, as well as allowing components with different shapes to be automatically placed on the die plate. ASM 898 die attacher is also equipped with a machine monitor to configure process settings and monitor the production process. This includes data logging and analysis capabilities, as well as machine health and security management options. Moreover, the machine is also equipped with a user-friendly human-machine interface, displaying the needed information during production, allowing the operator to easily keep track of the entire process.

There are no reviews yet