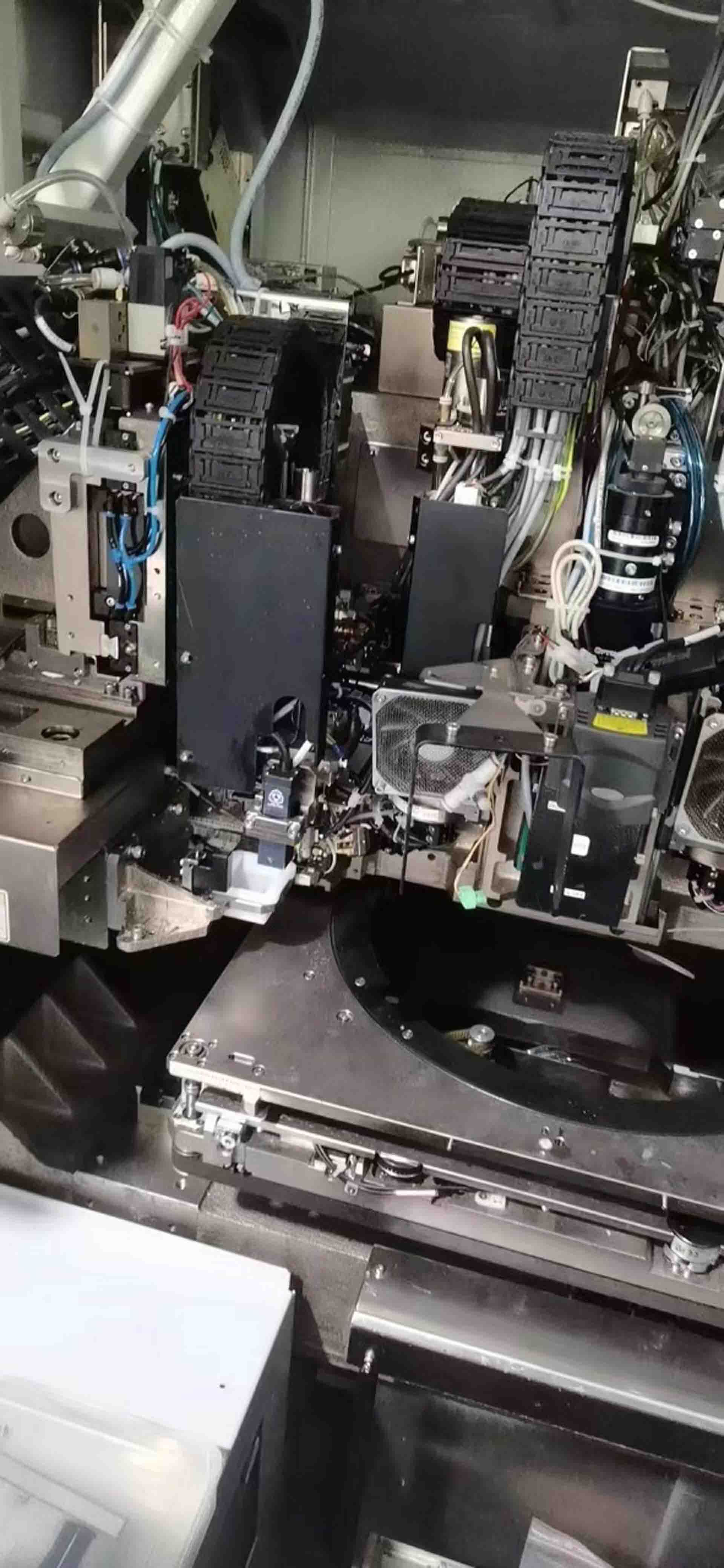

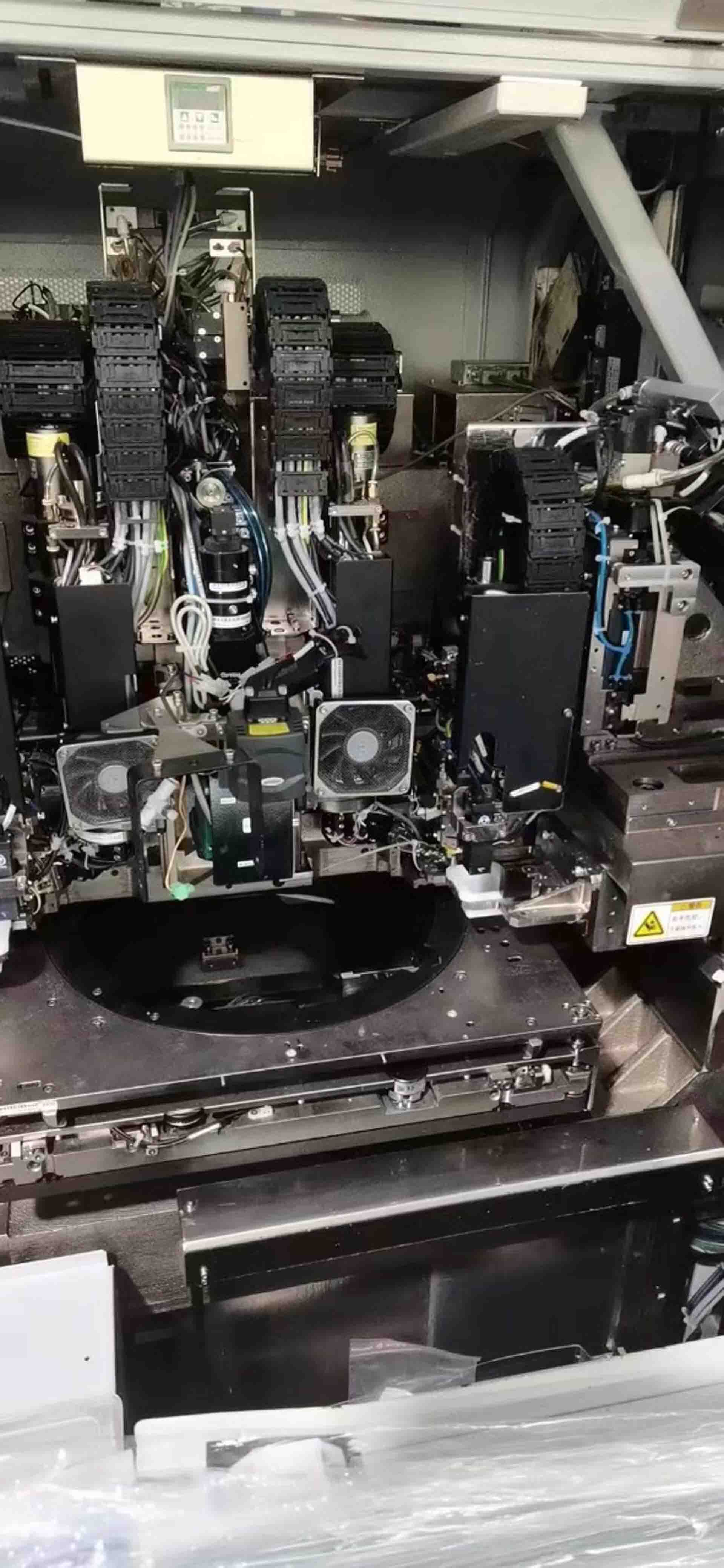

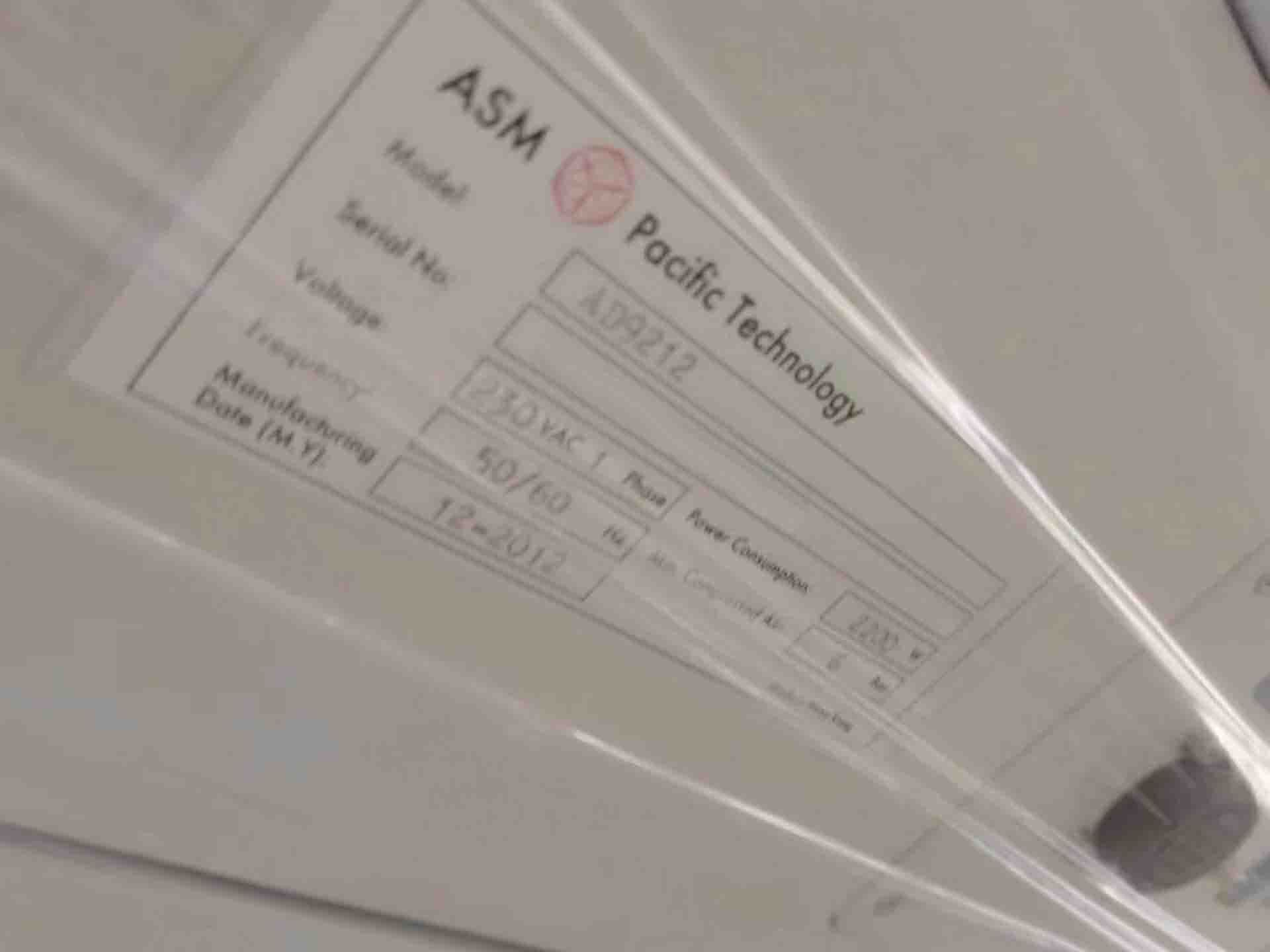

Used ASM AD 9212 #293626761 for sale

URL successfully copied!

Tap to zoom

ASM AD 9212 is an automated die attacher used in the production of semiconductor components. The device is designed to automatically apply a die attachment material to the backside of a semiconductor die. The process is controlled by an intuitive user interface, making it easy for operators to monitor and adjust parameters throughout the attaching process. The device is composed of several distinct components. A die holder unit is the first of the components and is responsible for securely placing a die before the attachment process begins. This unit is designed so that a vacuum can be activated to hold the die in place before the attachment process initiates. The next component is the die attach head, which is responsible for applying the die attach material to the backside of the die. The head is controlled by a stepper motor, which is programmed by the user interface to precise die locations. This head also contains several nozzles which allow for precise application of the die attach material. Next is the pre-heat station, which is designed to heat the die and substrate of the die prior to the die attaching process. This separate station is designed to reduce the time needed to process each die and ensure a good thermal connection between the die and substrate. Finally, ASM AD9212 has an independent vision unit which is used to ensure that the die is correctly placed on the target substrate. This includes checking for warped substrates, misaligned dice, and placement of the die attach material. In addition to these components, AD 9212 also contains several other features which make the system more user friendly. Features such as multiple nozzle configurations, adjustable processing parameters, and a remote monitoring system make sure that the device is able to quickly and accurately attach semiconductor dice to substrates. Overall, AD9212 is a highly capable automated die attacher. Its intuitive user interface and robust components make it a reliable tool for production processes in the semiconductor industry.

There are no reviews yet