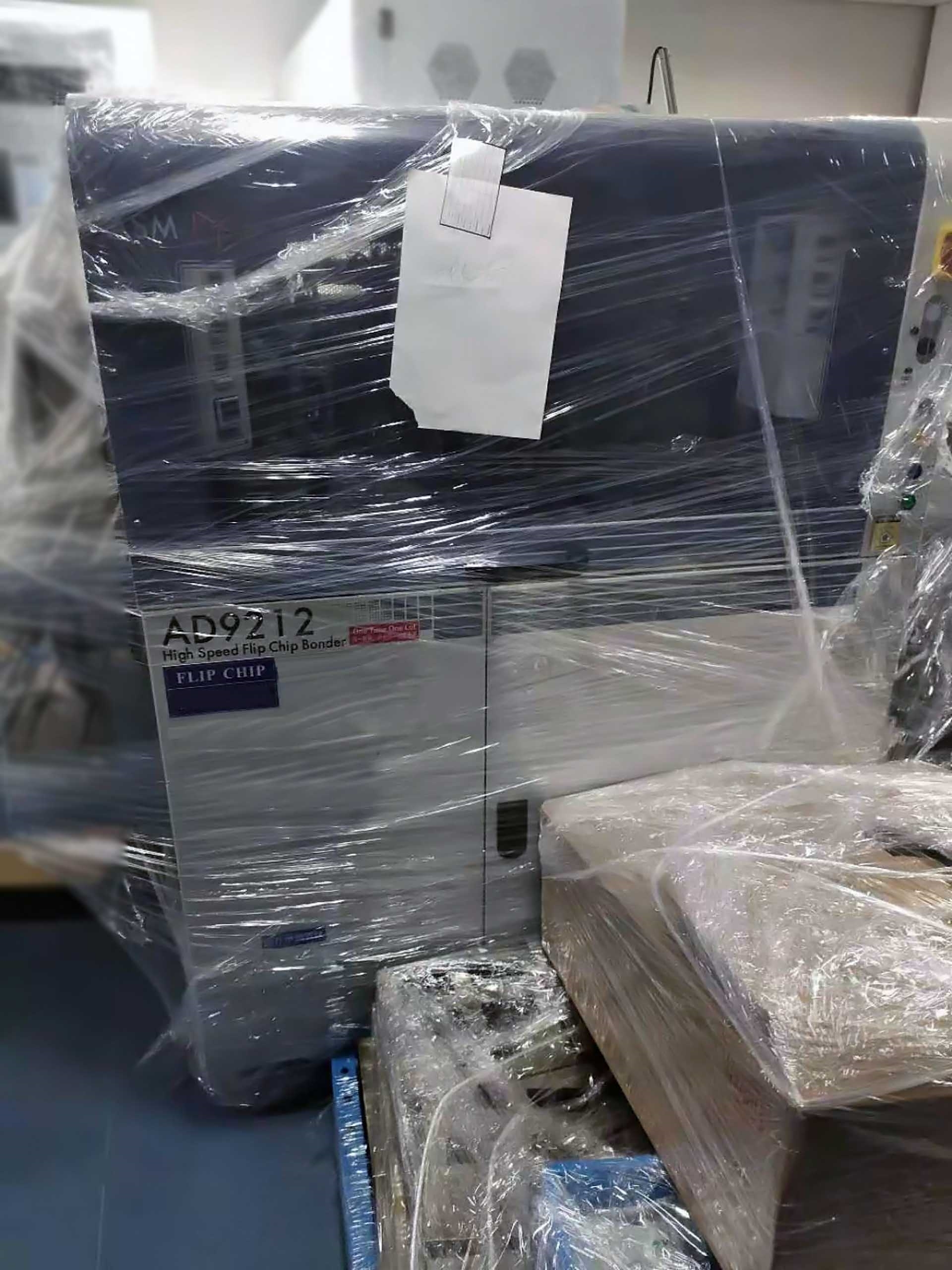

Used ASM AD 9212 #9260057 for sale

URL successfully copied!

Tap to zoom

ASM AD 9212 is a semi-automatic die attaching machine designed for die attach assembly of two different component sizes with up to nine die attach discs. It is fully automated with a programmable logic controller (PLC)-controlled main computer and manual control procedures for setting parameters and operations. It features a multi-axis motion equipment to accurately position and feed die-attach discs into place. The mounting table is equipped with linear motion actuators to move three mounting groups of the die-attach discs into position with high accuracy. ASM AD9212 is equipped with process regulation monitoring components in order to provide consistent and repeatable process operations. It has a user-friendly machine interface with a LCD touch screen and keyboard input, allowing operators to easily access the machine's programs, error history and operational settings. AD 9212 is designed to reliably process a variety of components, such as active components, resistors, ceramic capacitors, connectors and terminals. AD9212 features a unique feedback process control system and a high-sensitivity security unit. The feedback process control machine provides information such as temperature and pressure within the component, which the operator is able to regulate for a quality output. The high-sensitivity security tool includes a receptacle for security components, proximity sensors for detecting workpiece feed direction and pressure sensors for preventing component damage. ASM AD 9212's die-attach process is completed in three phases: preheating, die attaching and chamfering. During preheating, the parts are preheated in order to enable a successful attachment between them. The die-attach phase involves the application of pressure, heat and vibration in order to ensure proper adhesion of the part. The chamfering phase involves the fine levelling of the attached part in order to achieve a smooth surface. In terms of safety, ASM AD9212 is equipped with an emergency stop button and a self-diagnosis asset to detect any machine irregularity. Additionally, the machine features an electromechanical interlock model to prevent any accidental movement of the carriage or the die attach disc heads during operation. As a result, the machine is one of the safest and most reliable die attaching machines available.

There are no reviews yet