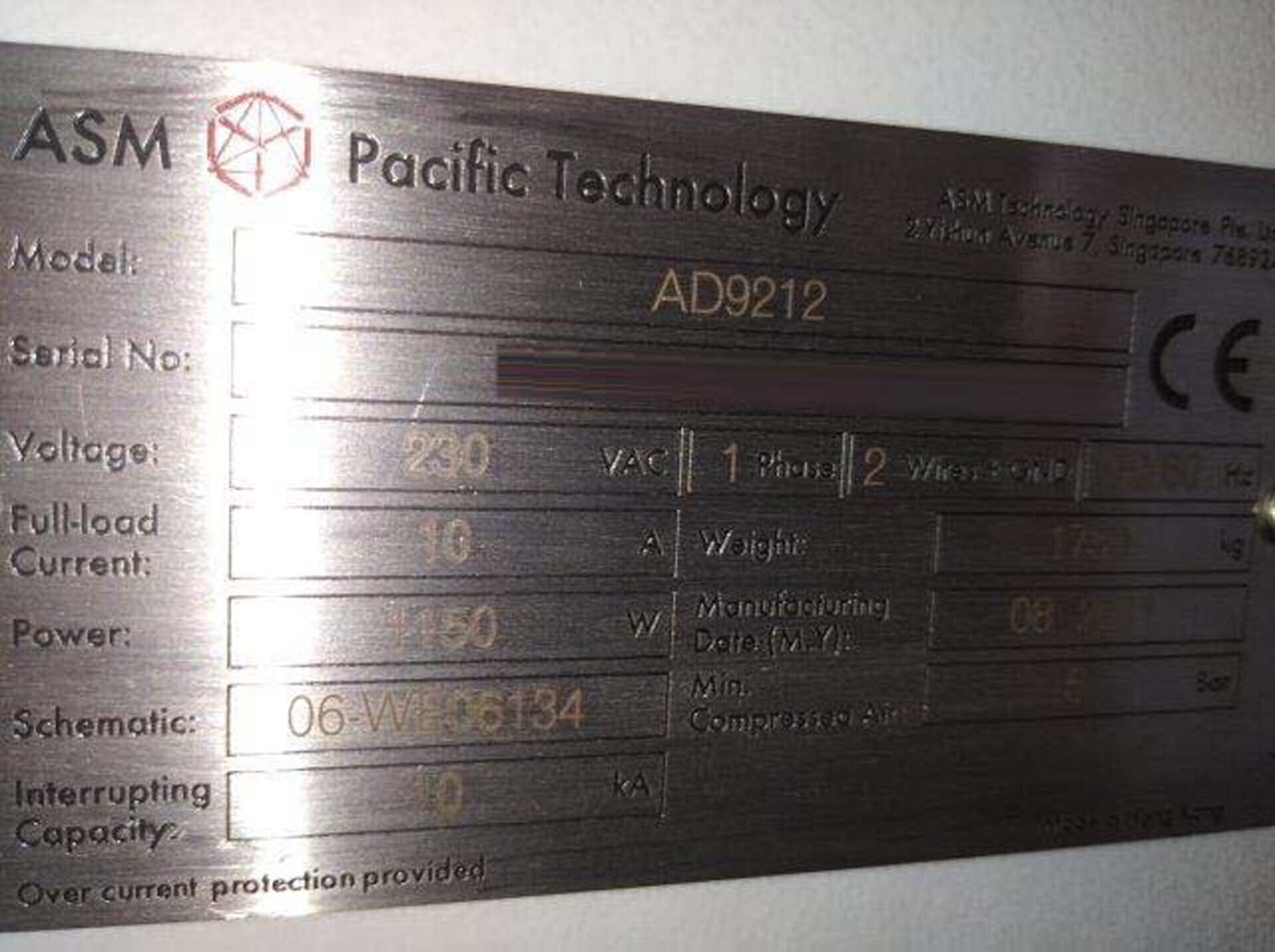

Used ASM AD 9212 #9304620 for sale

URL successfully copied!

Tap to zoom

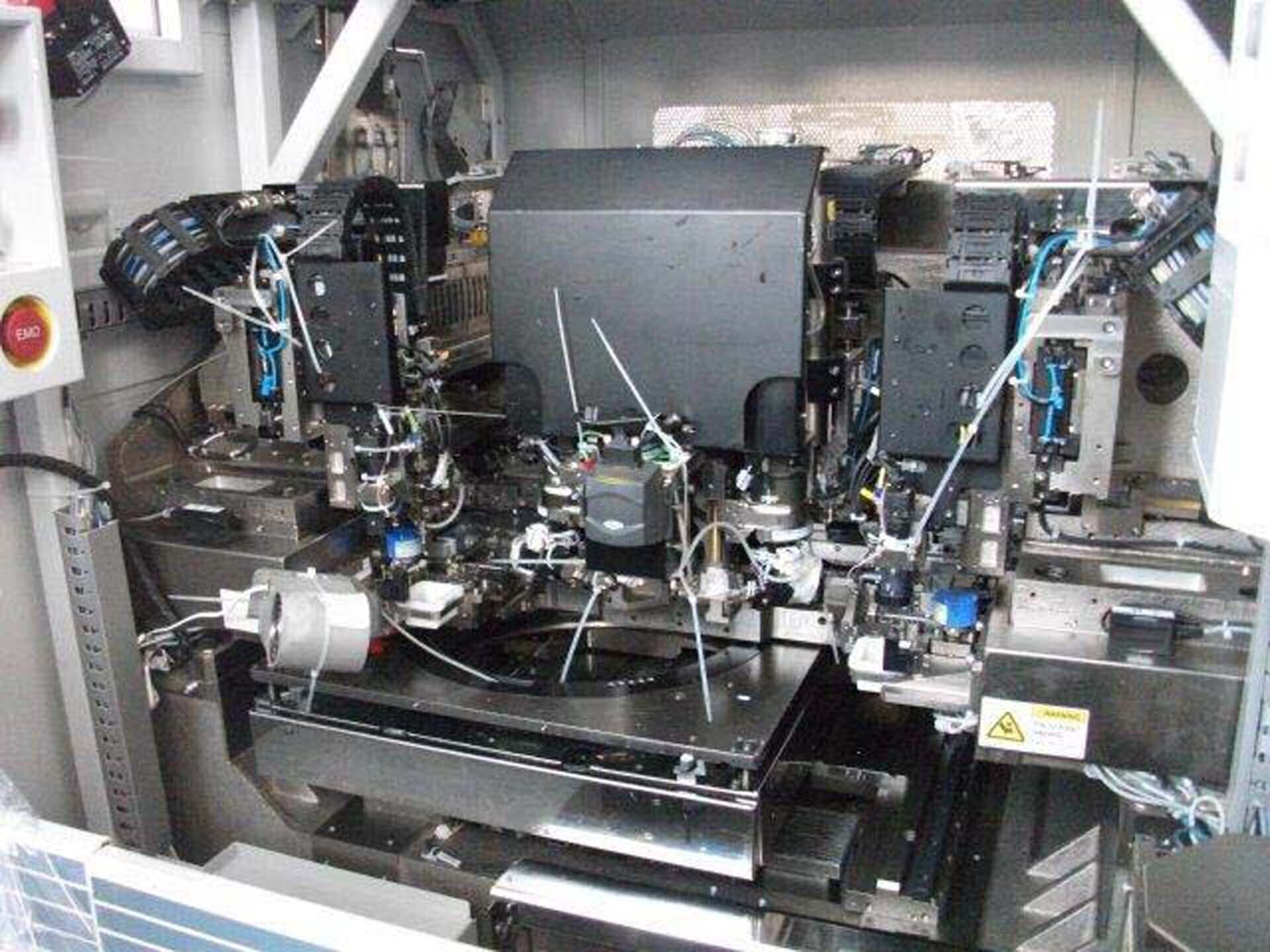

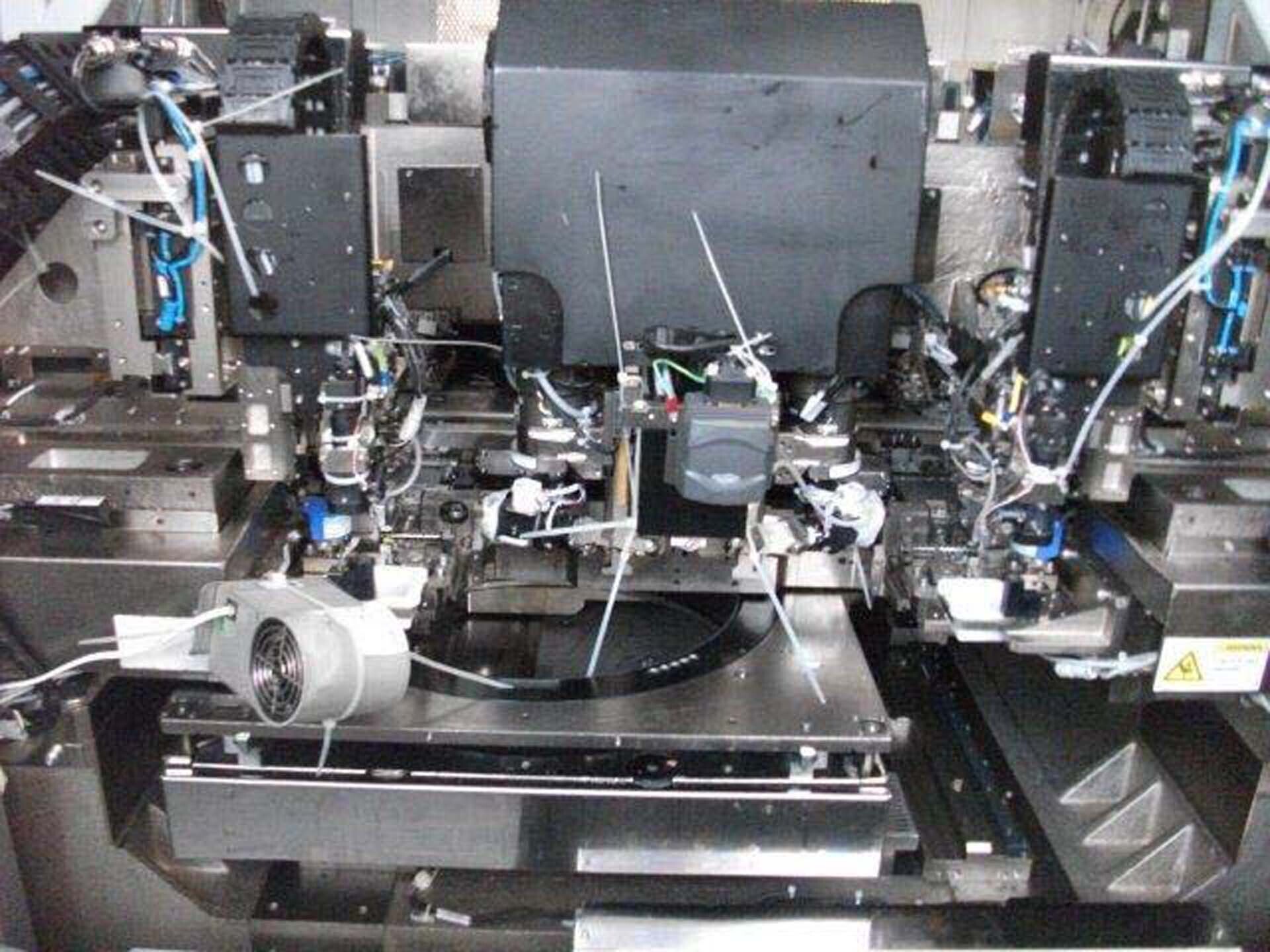

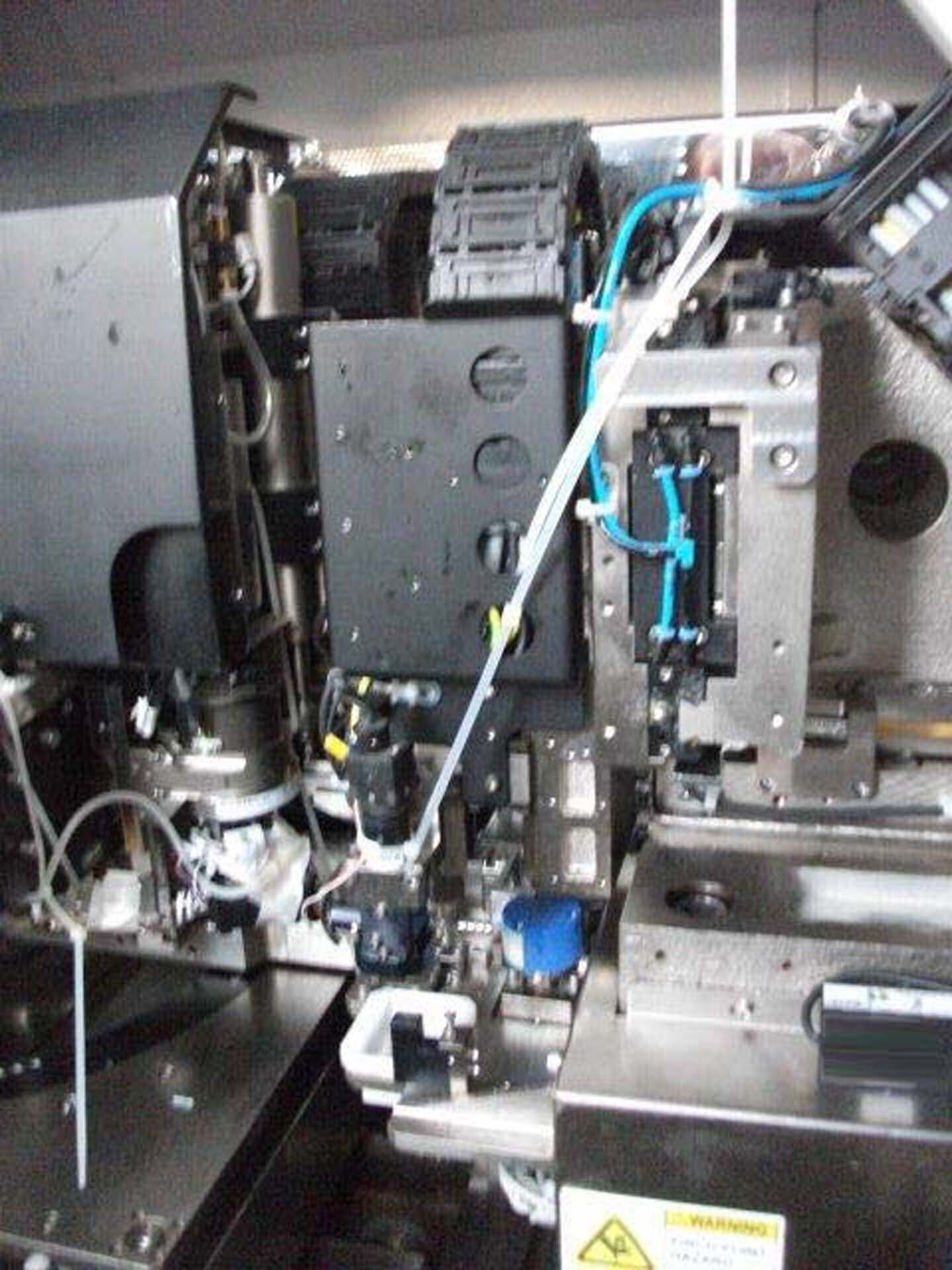

ASM AD 9212 die attacher is a precision production machine that is designed to attach tabs and other components to printed circuit boards. It utilizes a multi-head system for greater accuracy in the application of tabs. The machine is a PLC-controlled and servo-assisted and features a set of sensors to monitor the die attach process. This guarantees optimal accuracy, repeatability and flexibility in die attach operations. ASM AD9212 has a maximum work range of 4,000 cm2 and can be used on printed circuit boards up to 8 mil thick. The die attach speed of the machine is adjustable, allowing users to customize its performance for various applications. AD 9212 is equipped with a high-speed vision system for accurate and reliable placement of components onto the substrate. This system consists of a set of high-resolution cameras for image acquisition and on-board processing capabilities. This improves accuracy while still ensuring a fast and reliable process. AD9212 features an intuitive interface that allows users to quickly adjust settings or program the machine without specialized knowledge. The machine also features a number of advanced safety features such as a built-in safety sensor, an emergency stop button and an automatic shut-off feature. These features help ensure user safety and proper operation of the machine. ASM AD 9212 has proven to be a reliable, accurate and flexible tool for die attach operations. Its precision and durability make it an ideal choice for a variety of applications. With its advanced safety features and intuitive interface, ASM AD9212 is an excellent choice for automated die attach processes.

There are no reviews yet