Used ASM AD 9212 #9304623 for sale

URL successfully copied!

Tap to zoom

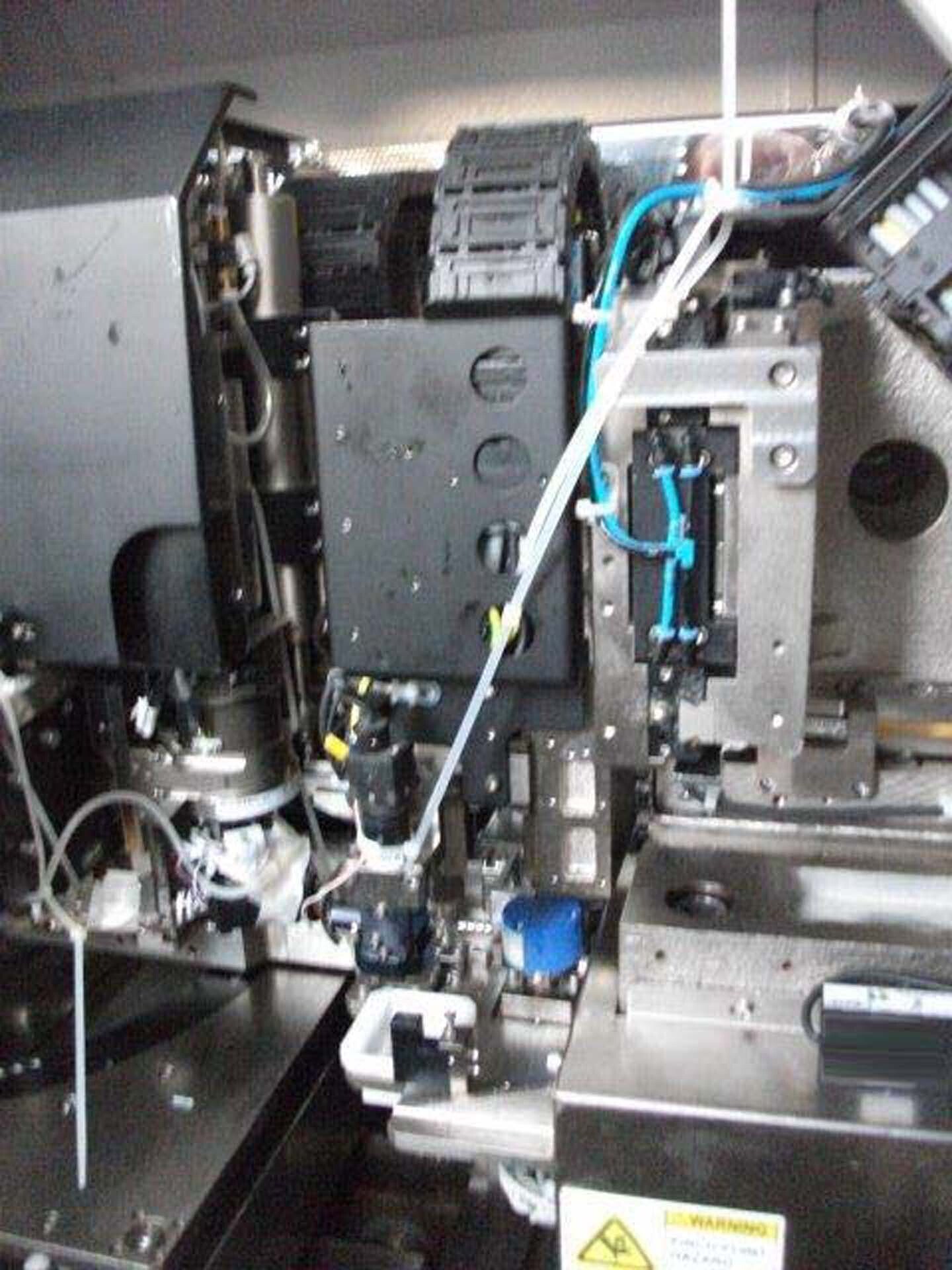

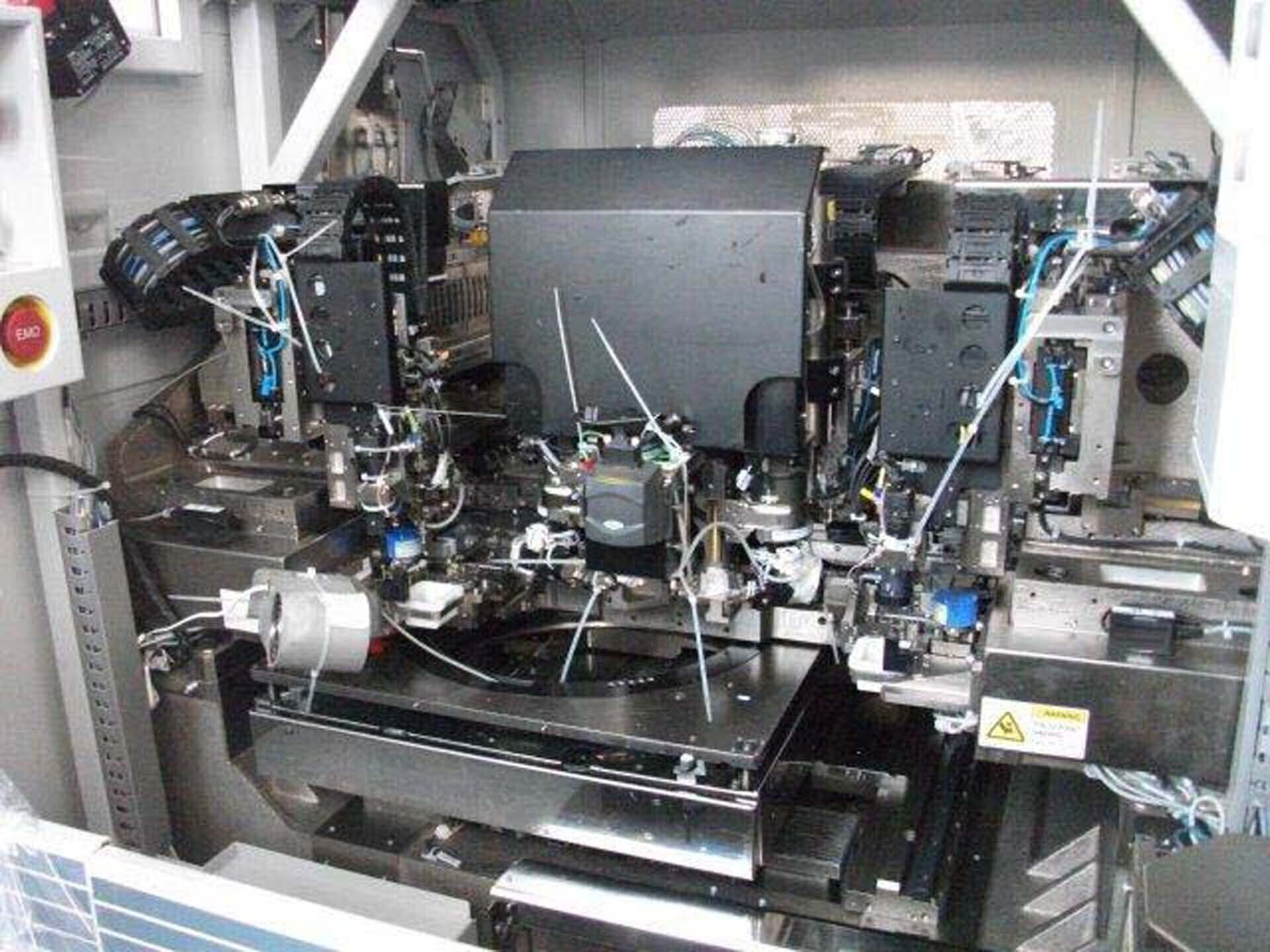

ASM AD 9212 is a die attacher designed for use in the assembly of precision microelectronic components. ASM AD9212 is an automatic die bonder equipment that is capable of placing and bonding die onto various substrates and packages quickly and accurately. This machine can be used with a variety of component types, including SMT parts, packages and other precision components. AD 9212 die attacher utilizes a highly accurate vision system that can detect and align die quickly and accurately. The vision unit determines the type of die, the bonding parameters and the proper die placement. This machine minimizes manual adjustment and reduces setup time. AD9212 die attacher also utilizes a pick and bond technology, which allows for repeatable and precise die placement, regardless of the component size or complexity. This tool allows for a wide range of bond lengths and pitches, allowing for increased versatility in assembly applications. ASM AD 9212 features several feeder technologies, allowing for a flexible feeder asset to match a wide range of component types. An Automated Nail Feeder can be used to accurately place nails into the die and a Platen Feeder can be used for larger components, such as packages or BGAs. The Systems's Platen Feeder will also accept a wide range of widths and pitches for more accurate placement. ASM AD9212 uses a proven dispensing process that utilizes a unique blade and shuttle model for faster, more accurate and more repeatable results. This equipment allows for a wide range of applications and a wide range of die pitches and sizes. AD 9212 system can be interfaced with all current and future die bonding systems, making it easy to integrate into existing production processes. This unit also has a built-in calibration and optimization procedure, ensuring accurate and efficient performance. AD9212 die attacher is a complete die attacher machine that offers precise, repeatable and reliable performance without sacrificing speed or accuracy. This user-friendly tool can be used to bond all types of components quickly and accurately, making it a great choice for microelectronic assembly applications.

There are no reviews yet