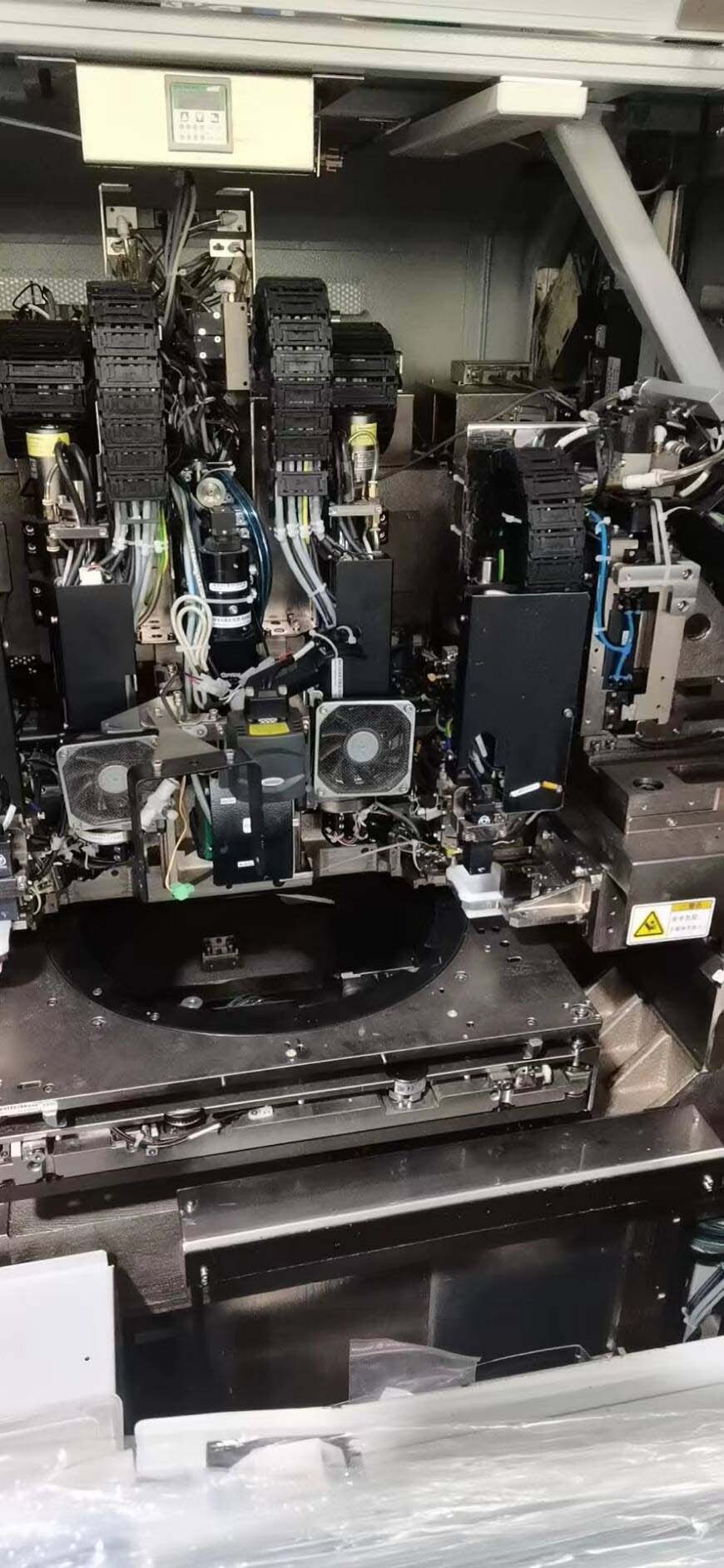

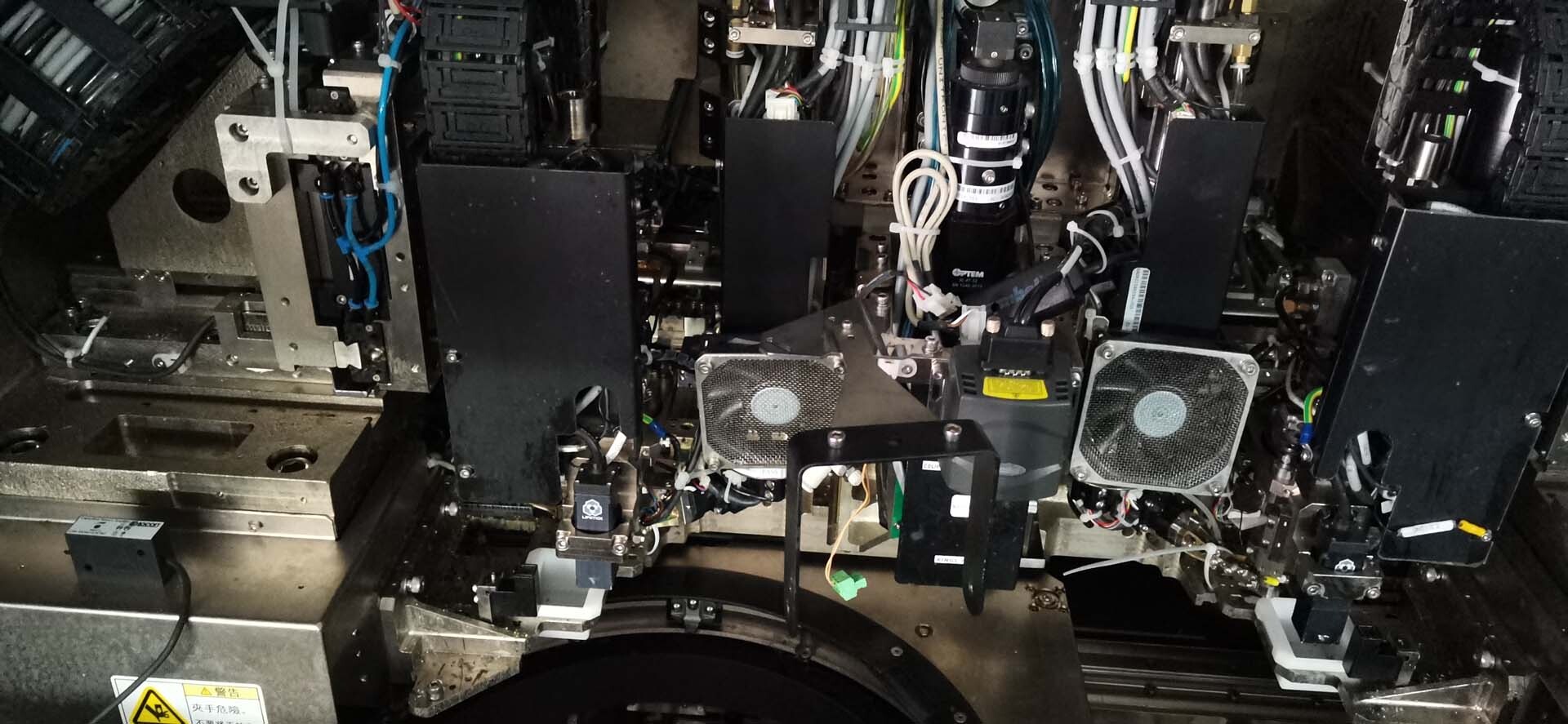

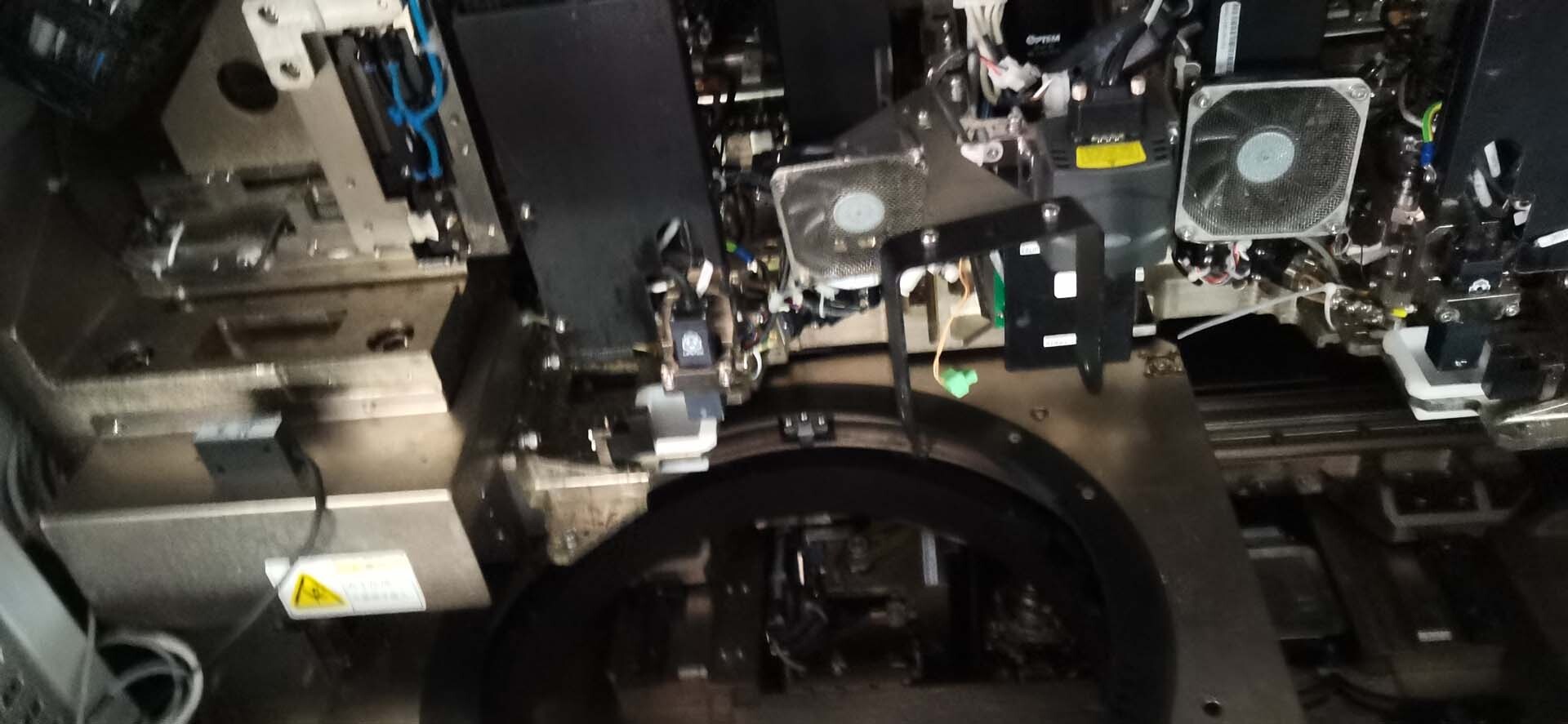

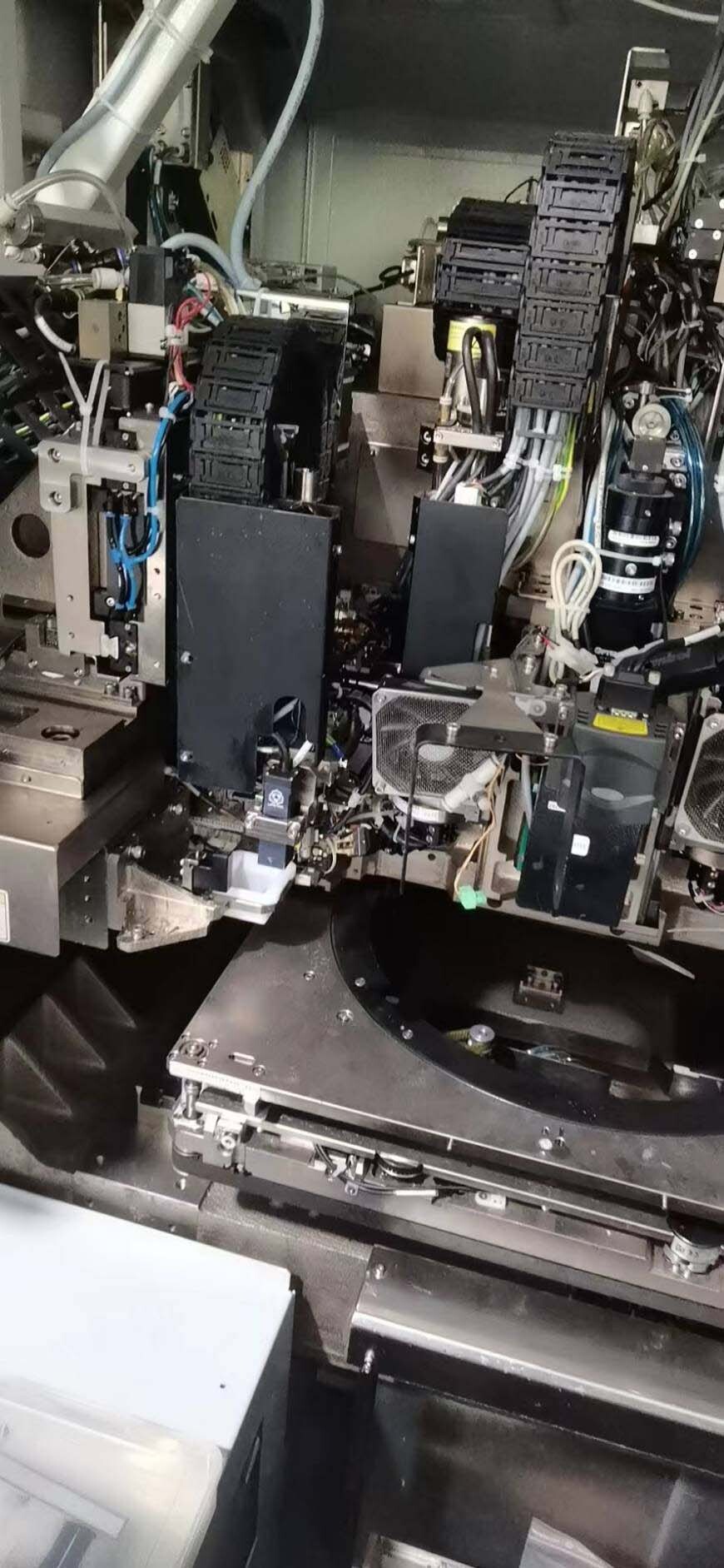

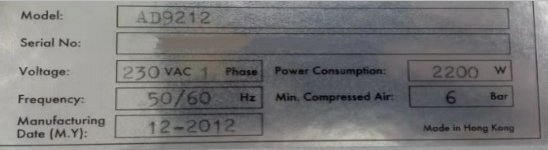

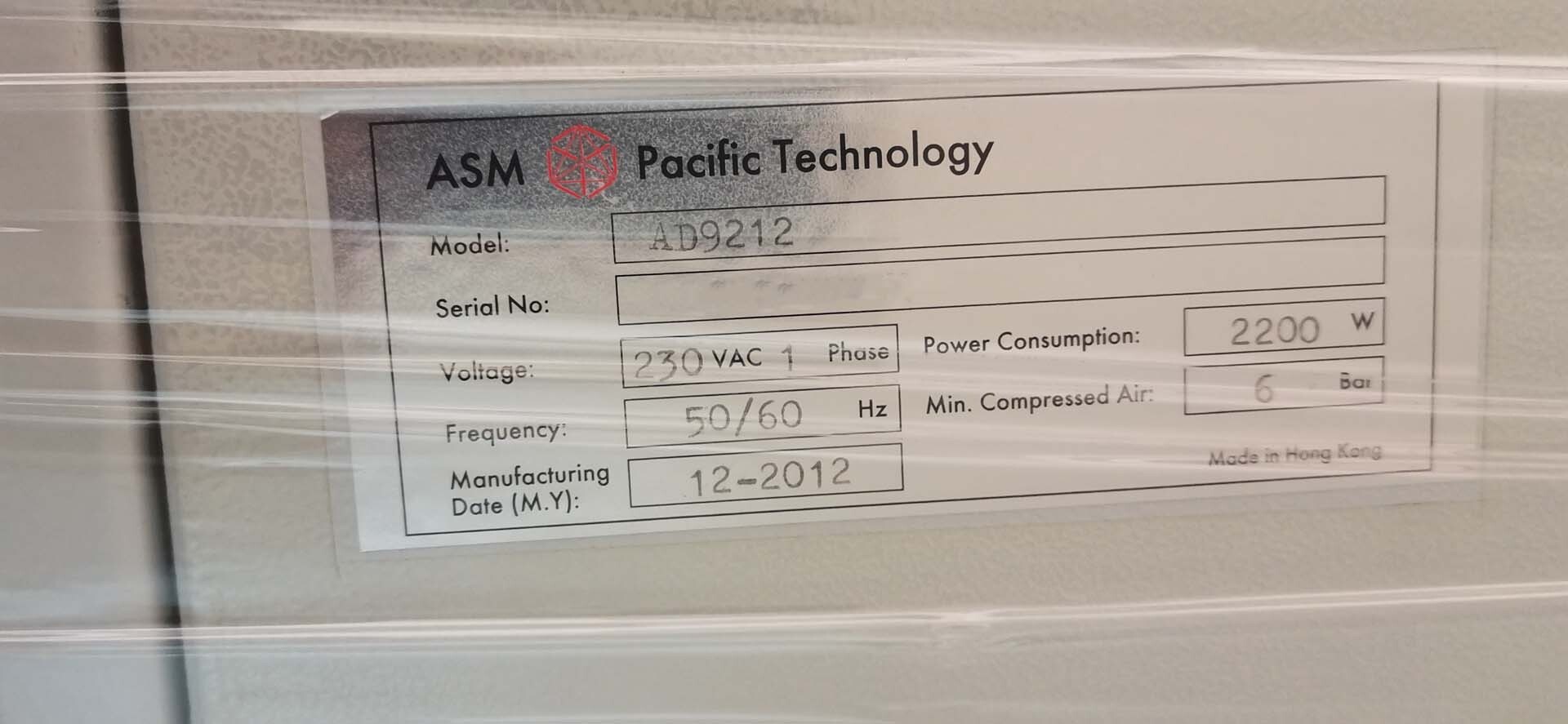

Used ASM AD 9212 #9362630 for sale

URL successfully copied!

Tap to zoom

ASM AD 9212 is a state-of-the-art die attacher designed put dies onto leadframes for manufacture of semiconductors. It is able to accurately and quickly attach as many as 15 leads at a time using a vision-based pick-and-place equipment. This enhances accuracy and speed over traditional manual methods, allowing for greater production outputs in less time. ASM AD9212 includes a high-resolution, five-axis positioner to ensure precise placement of each die. An optimized feeder system dispenses to the exact number of leads for a particular job with a minimum of waste. The die-attach process is low stress yet fast, making it suitable for a variety of die sizes, shapes and materials. The unit also provides the flexibility to perform multiple attach processes, like die trimming and pre-clean - with or without reset. AD 9212 also ensures complete process control throughout, with software incorporating feedback control for the precise locations needed for each die attach. Sensors detect the precise location of each die during the process, and on-machine scanning validates accuracy of vision-guided die placement. The process can also be fine-tuned for specific customer requirements. AD9212 is designed to be both highly dependable and simple to use. It is equipped with mechanical and vision alarms to rapidly identify machine malfunctions and correct errors on-the-fly. Meanwhile, the intuitive graphical user interface makes it easy for operators to set up, monitor and troubleshoot the machine when needed. Overall, ASM AD 9212 is an innovative and versatile die attacher that supports mid- to high-volume production of semiconductors. Its highly accurate delivery tool and process control features make it an attractive solution for users looking to achieve maximum productivity and quality. With its advanced design and user-friendly features, ASM AD9212 is the ideal choice for efficient and reliable die attachment.

There are no reviews yet