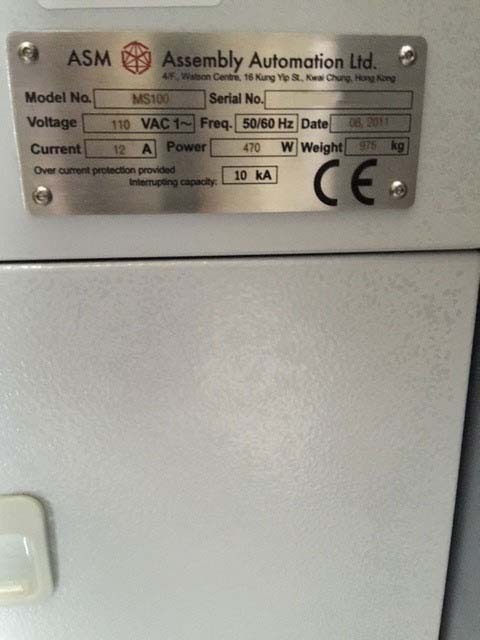

Used ASM MS 100 #293635954 for sale

URL successfully copied!

Tap to zoom

ASM MS 100 is a type of manual die attacher used to permanently affix two or more components together quickly and efficiently. This type of die attacher is equipped with a manual press that uses a single lever to drive a die cutter into the materials used for assembly. This die cutter can be used for die cutting, stamping, bending, and marking applications. ASM MS100 is designed to be used in the industrial and manufacturing fields, with an emphasis on high-volume production. It is capable of attaching multiple parts at once, thanks to its compact design and easy loading of material. The die cutter has a die closet that can take up to four dies of different sizes and shapes, allowing for a range of applications. The die cutting and attachment process can be done with a maximum force of 3.8 bar (380 kg) per cycle, which ensures a secure and strong assembly of the components. MS 100 is based on a twin-lever design that uses two separate drives. One drive is used to activate the die cutter, while the other is used to operate the pressure pad. This allows for high accuracy and is able to produce a consistent force on the connected components. With a clamping force of up to 21.6kN (2160kg), this manual die attacher is suitable for high-volume assembly jobs. MS100 is powered by a 220V, 1-phase power supply and is capable of continuous operation. Additionally, it comes with a built-in vacuum system that allows the user to securely hold the components together, reducing the risk of accidental disconnection. In addition, the system allows for easy feed-out of material during attachment and for quick changeover between parts, allowing for maximum efficiency. ASM MS 100 is suitable for a wide range of parts, from small to large, for both metal and plastic components. It also features a self-centering die plate, allowing for precision and repeatability in attached parts. All in all, ASM MS100 is an excellent choice for efficient and precise assembly of components, and can help to reduce labor costs and improve the speed of production in the long run.

There are no reviews yet