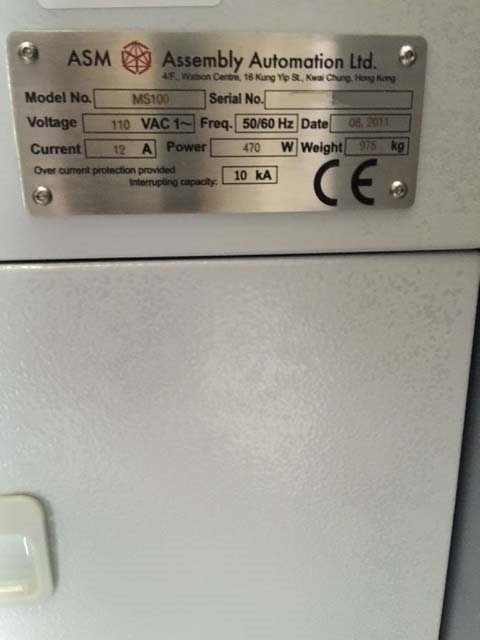

Used ASM MS 100 #9149908 for sale

URL successfully copied!

Tap to zoom

ID: 9149908

Vintage: 2011

Wafer mapping die sorter

I-Flow process (LED)

DISCO Film / Wafer frame: Up to 6"

Map sorter

Cycle time for map sorting: ~175 ms

Latest motion technology

Average placement accuracy: ±1 mil

Die rotation range: 1°

Direct couple bond head

With dual arm pick and place process

2011 vintage.

ASM MS 100 is a fully automated die attach machine designed for a wide range of applications in the electronics manufacturing industry. It is designed with a modular configuration that makes it a great fit for any production environment. The equipment is designed to make precision die attach operations efficient, accurate and cost-effective. The machine has a dual bonding head with automatic alignment and is capable of handling a variety of package types like Trays, Wafer Carriers, and Dynamic Thermoforming. As a result, the machine is versatile enough to adapt to changing production needs. ASM MS100 is equipped with several advancements that make die attach applications run with optimum efficiency. Its advanced vision technology permits accurate part positioning and a high-precision pick & place system directs the part directly to the die attach process locality. A hot melt adhesive jetting unit is used to dispense the die attach adhesive accurately and evenly. The dual head processing mechanism ensures continuity of throughput, so the parts can be attached faster. The machine is also designed for easy maintenance and operational improvements with spares that are available on demand. MS 100 is equipped with superior motion control technology to ensure precise part movement and has full process capability for SMD, BGA, CSP and other package types. The machine's robust automated thermal management software ensures secure cycle times and repeatable accuracy for every application. Operator friendly interfaces make the tool user friendly for operation and maintenance. Furthermore, its modular design enables upgrades with increased production levels with real-time adjustments and optimization. The machine is also built with a secure enclosure to meet high safety standards in conformance with the CE standards. This ensures an overall safe production environment. With its performance enhancing features, MS100 is an ideal die attaching asset that provides superior production cycle times as well as increased production volumes.

There are no reviews yet