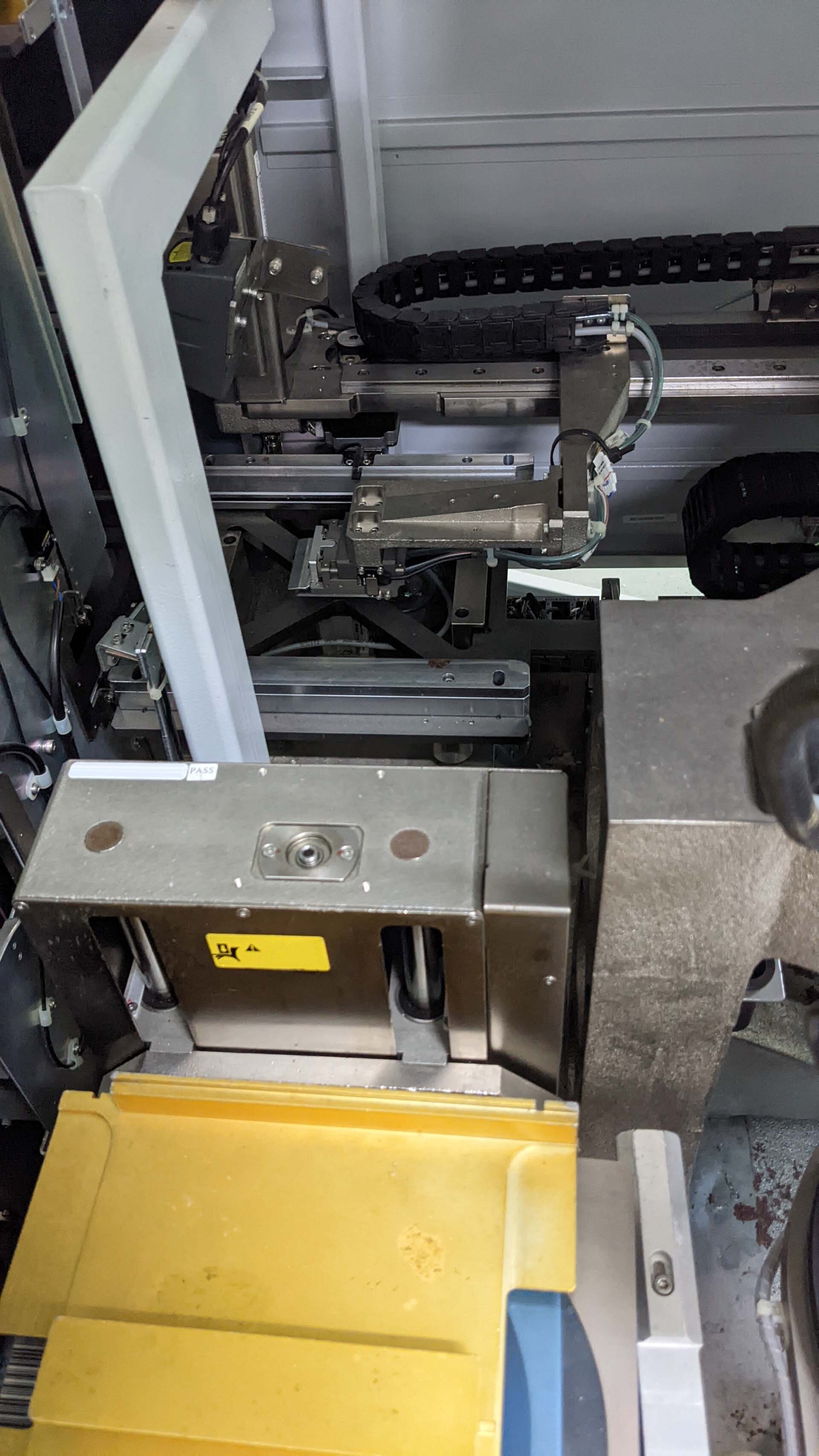

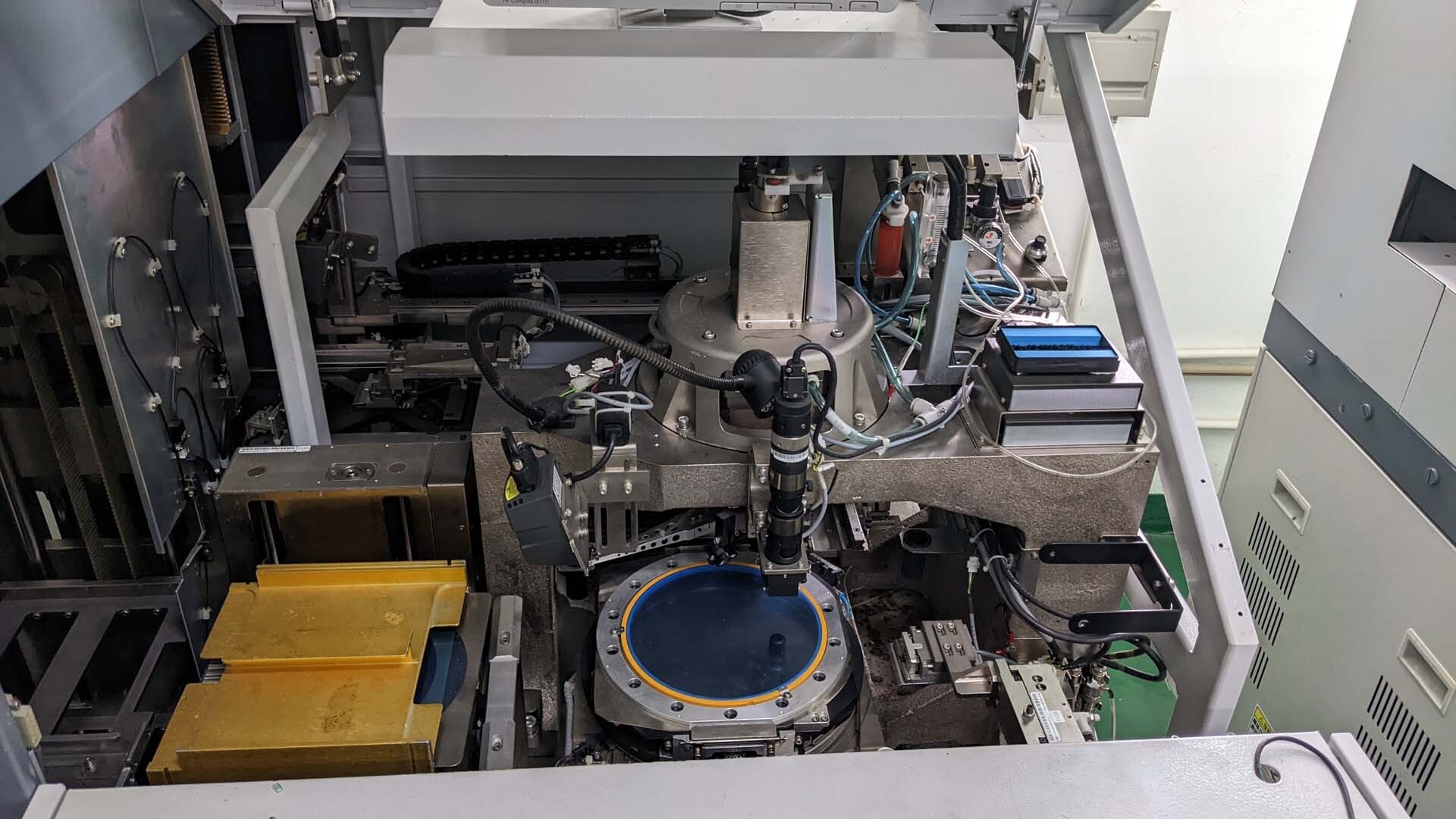

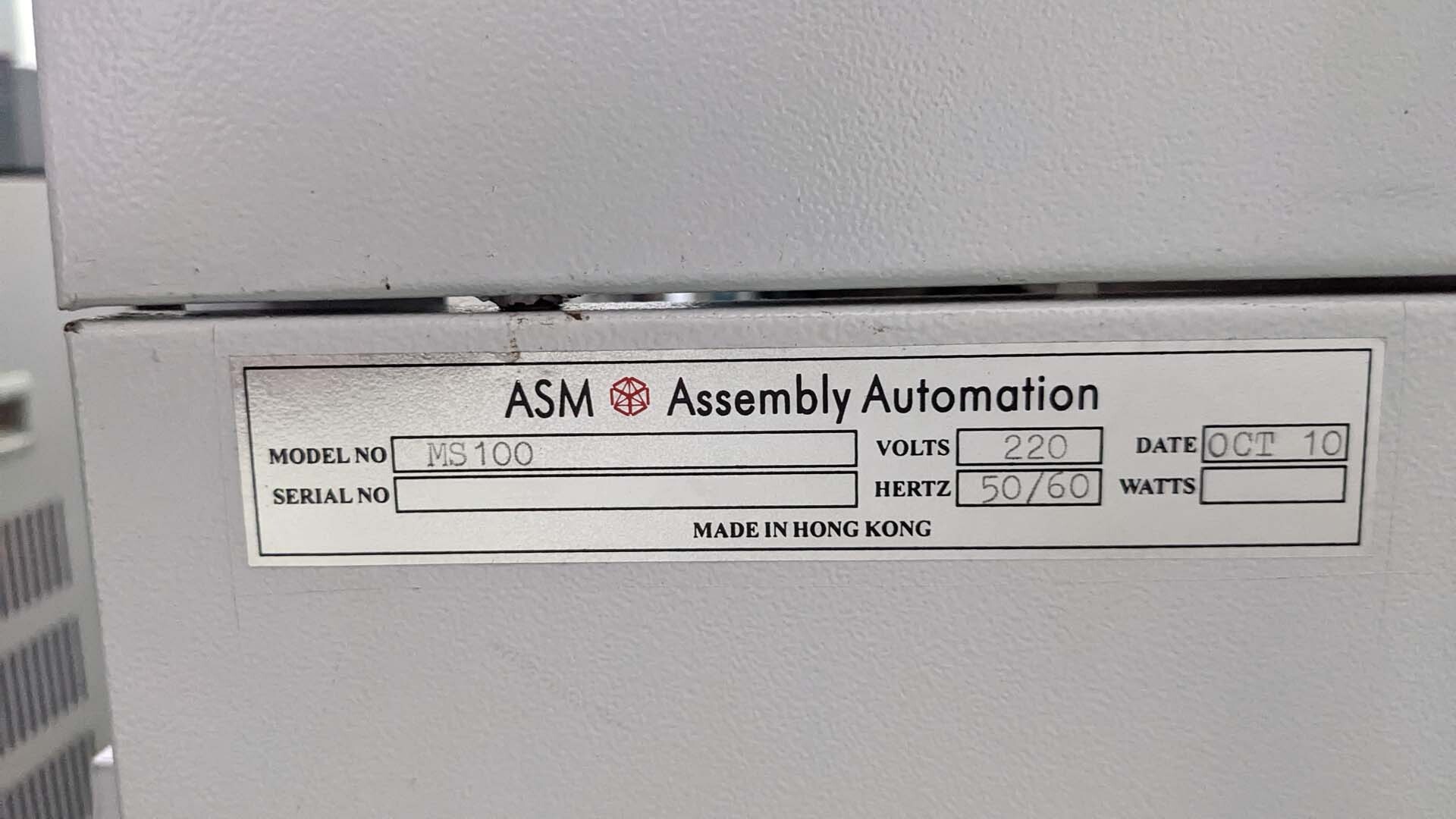

Used ASM MS 100 #9364712 for sale

URL successfully copied!

Tap to zoom

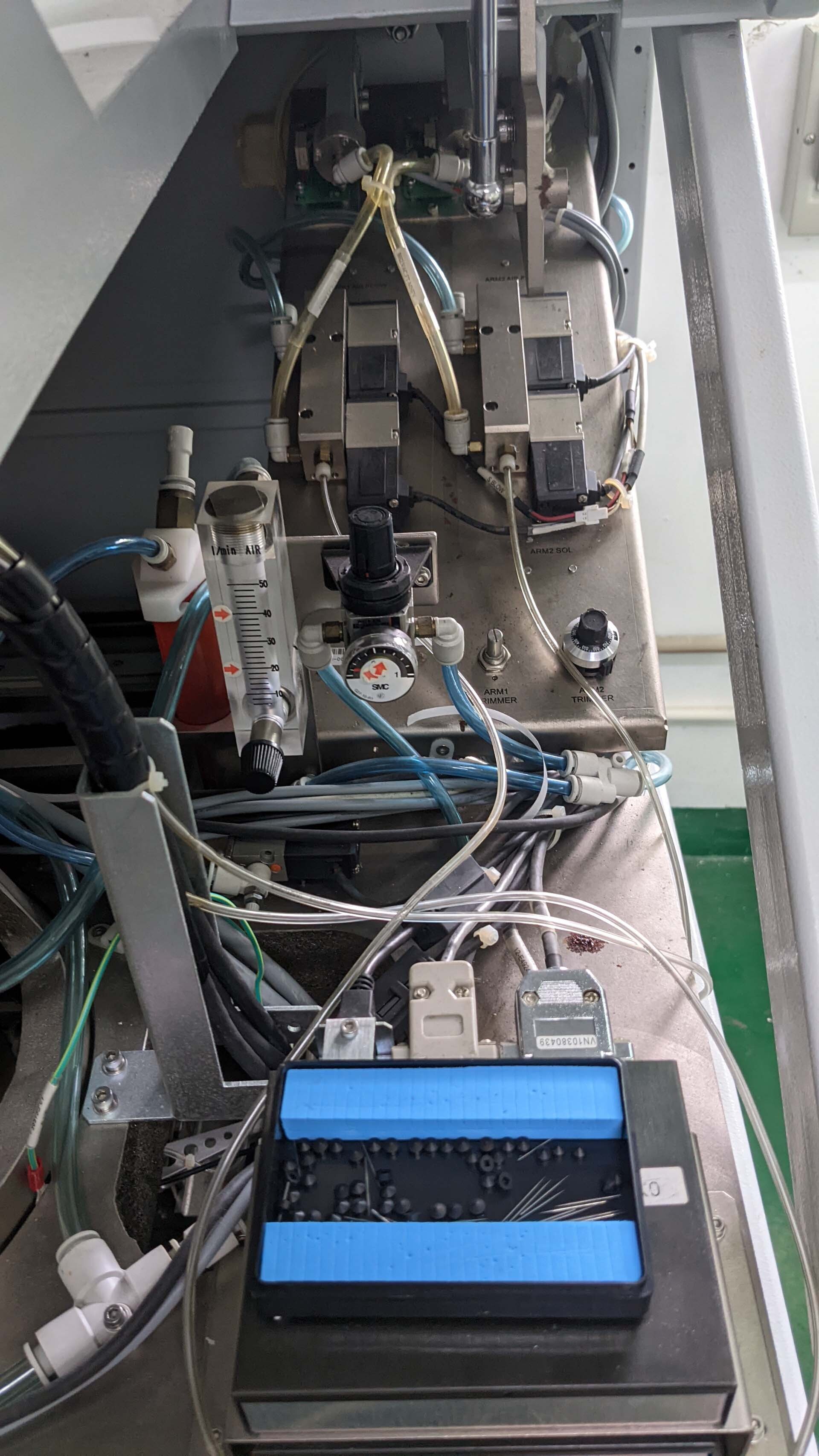

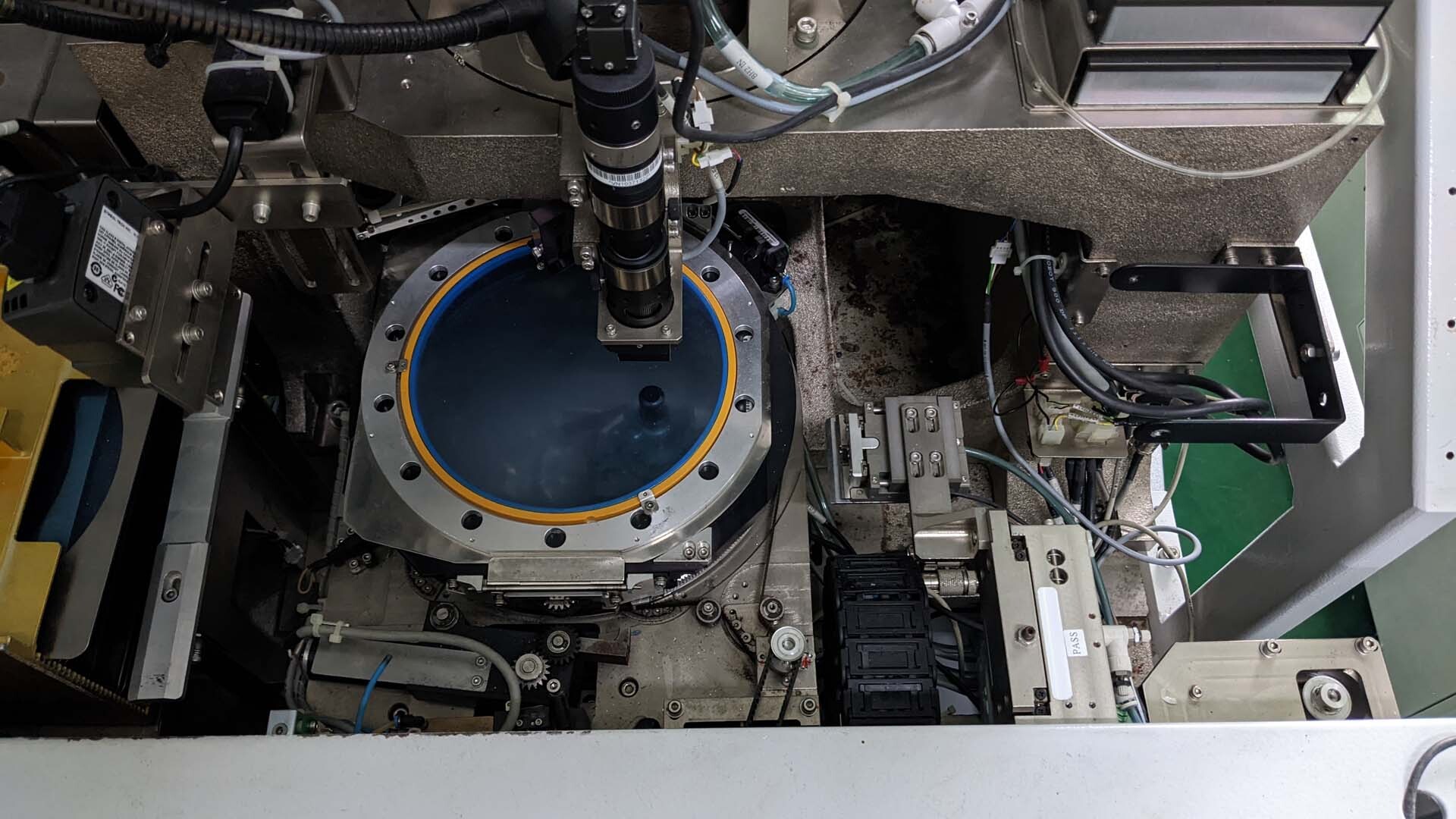

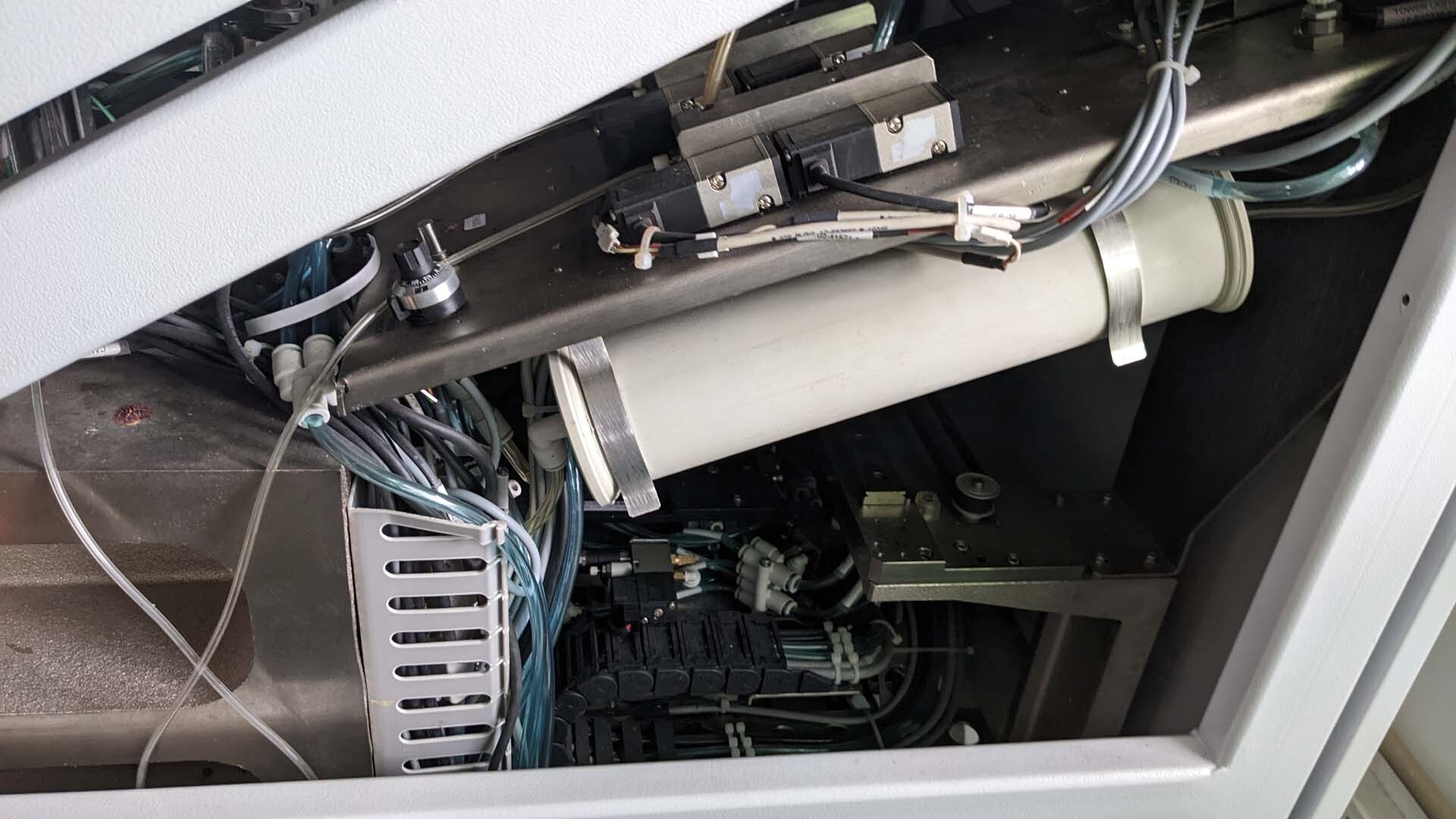

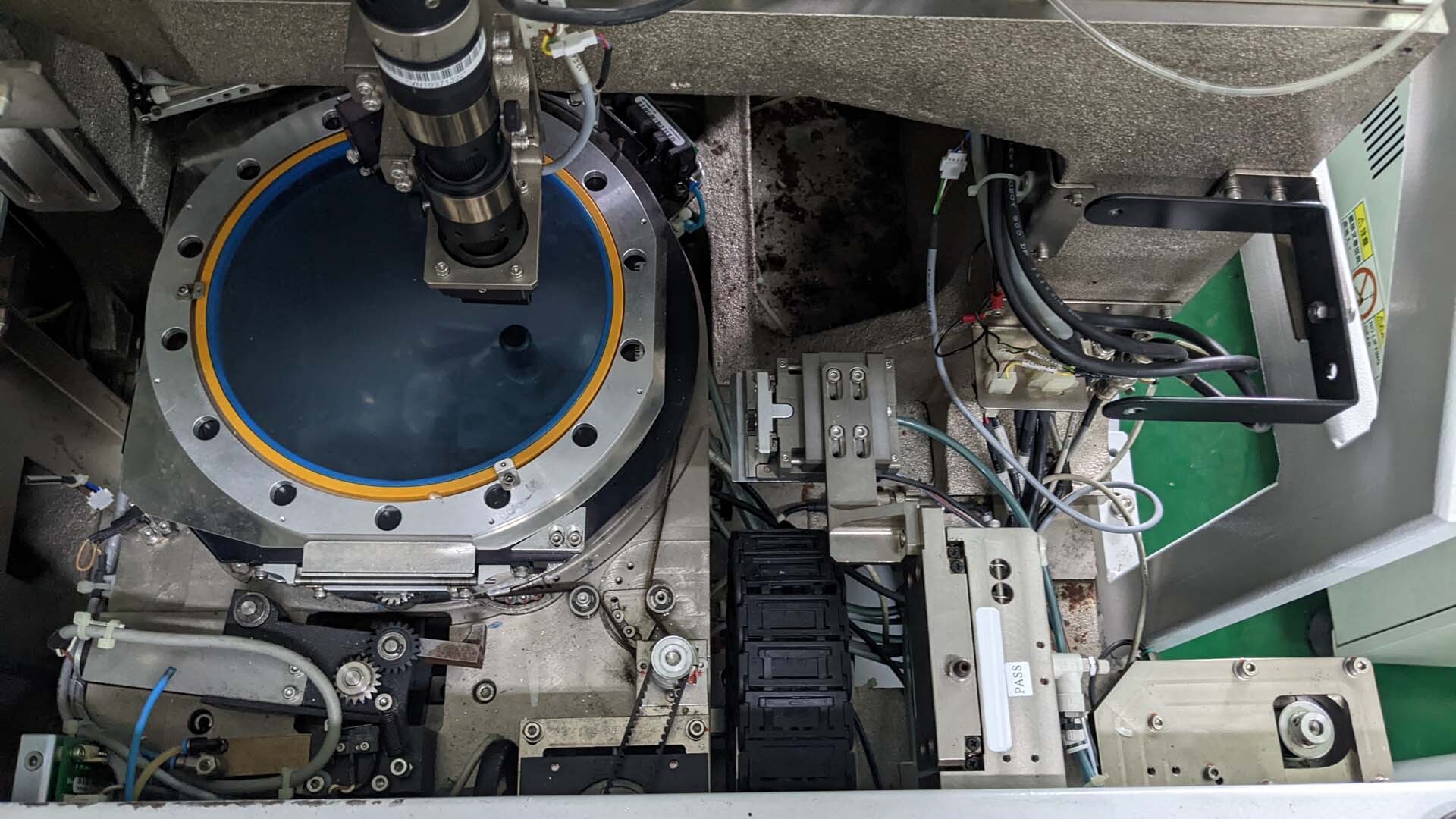

ASM MS 100 is a die attacher used in the automation and robotization of die-bonding processes. Utilizing advanced technology, this machine helps to simplify the delicate and labor-intensive task of attaching dies accurately onto a substrate. This machine can help to reduce quality control costs, production time, and labor costs. ASM MS100 consists of a servo axis motor unit for accurate and reliable die placement. It also features a die clamp, vision system, and die rate regulator for real-time feedback on the attachment process. The die rate regulator is also designed to monitor the entire process, ensuring that accurate and effective die bonding is achieved. MS 100 uses advanced machine vision technology to inspect the dies prior to attachment. This helps to ensure that the dies are placed accurately and consistently. In addition, the vision-based orientation optimization can align dies precisely in order to achieve the best results. Additionally, the machine is compatible with both traditional dies and foam-based die strips. This enables users to optimize the process by using different die sets. The vision system also features defect inspection, ensuring that defects in dies during the attachment process can be detected and corrected. Additionally, the machine has integrated built-in safety features such as electrostatic discharge protection, to ensure that the dies are not damaged during the process. MS100 is designed to be highly adjustable, allowing it to be used in different die-bonding configurations. This allows the machine to apply a wide variety of dies, including those with curved attach surfaces. It is also capable of handling complex die-bonding processes, such as those with high qualification requirements. Finally, ASM MS 100 is relatively compact, and is capable of being integrated into existing assembly lines. This allows users to achieve maximum efficiency by automatically feeding dies to the machine as part of the line. This makes the machine ideal for both high-volume manufacturing and flexible production.

There are no reviews yet