Used ASM MS 100 #9409635 for sale

URL successfully copied!

Tap to zoom

ID: 9409635

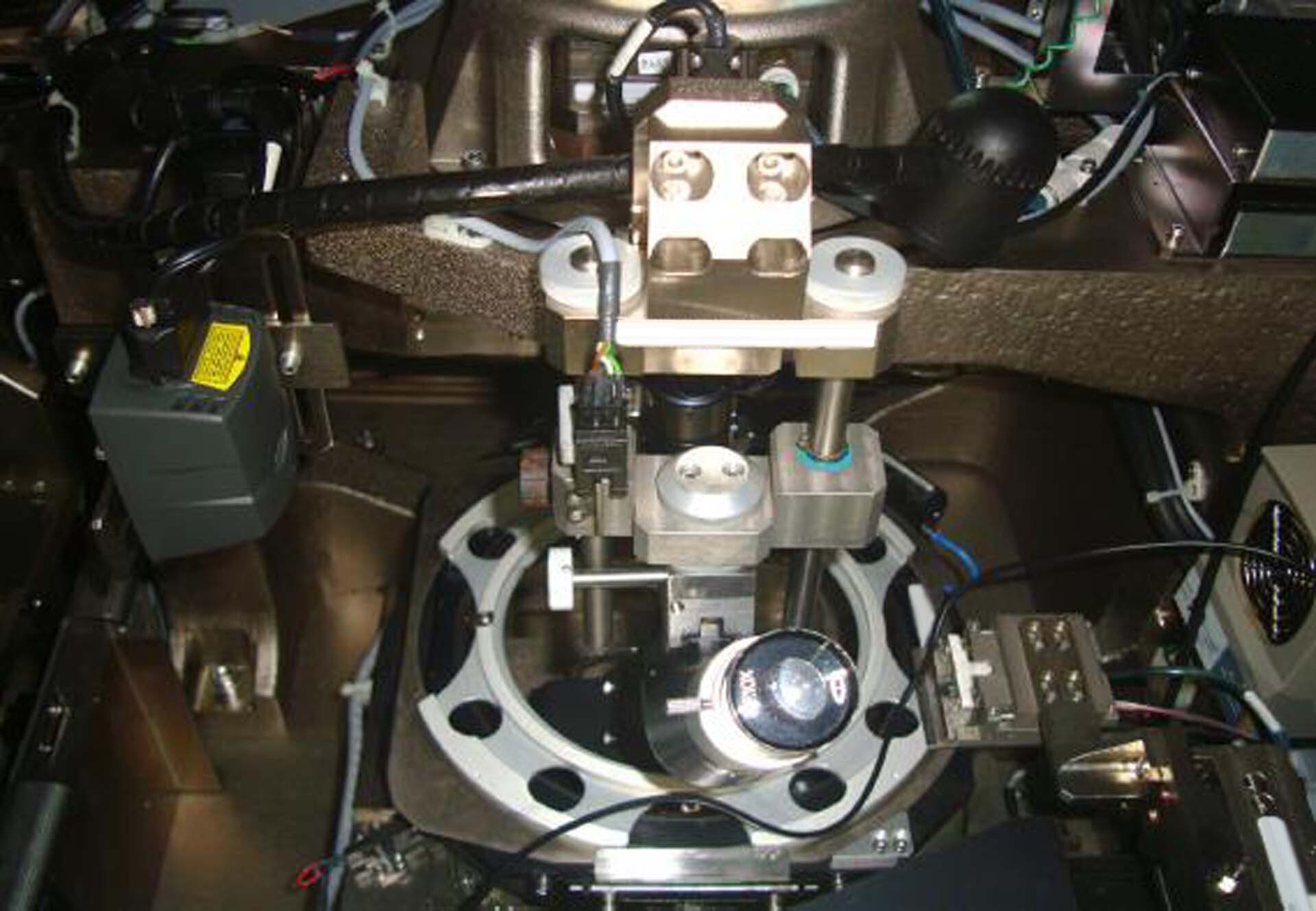

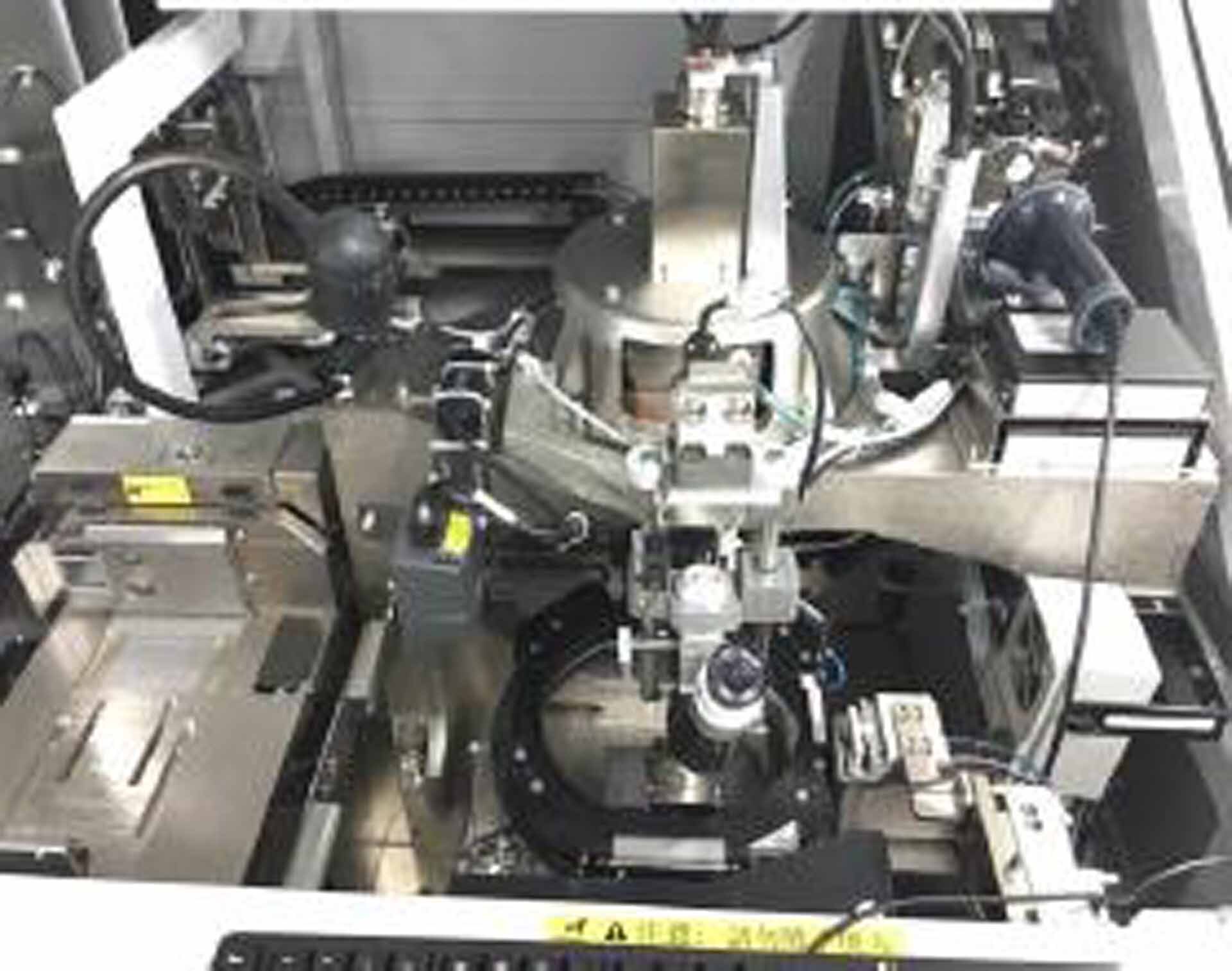

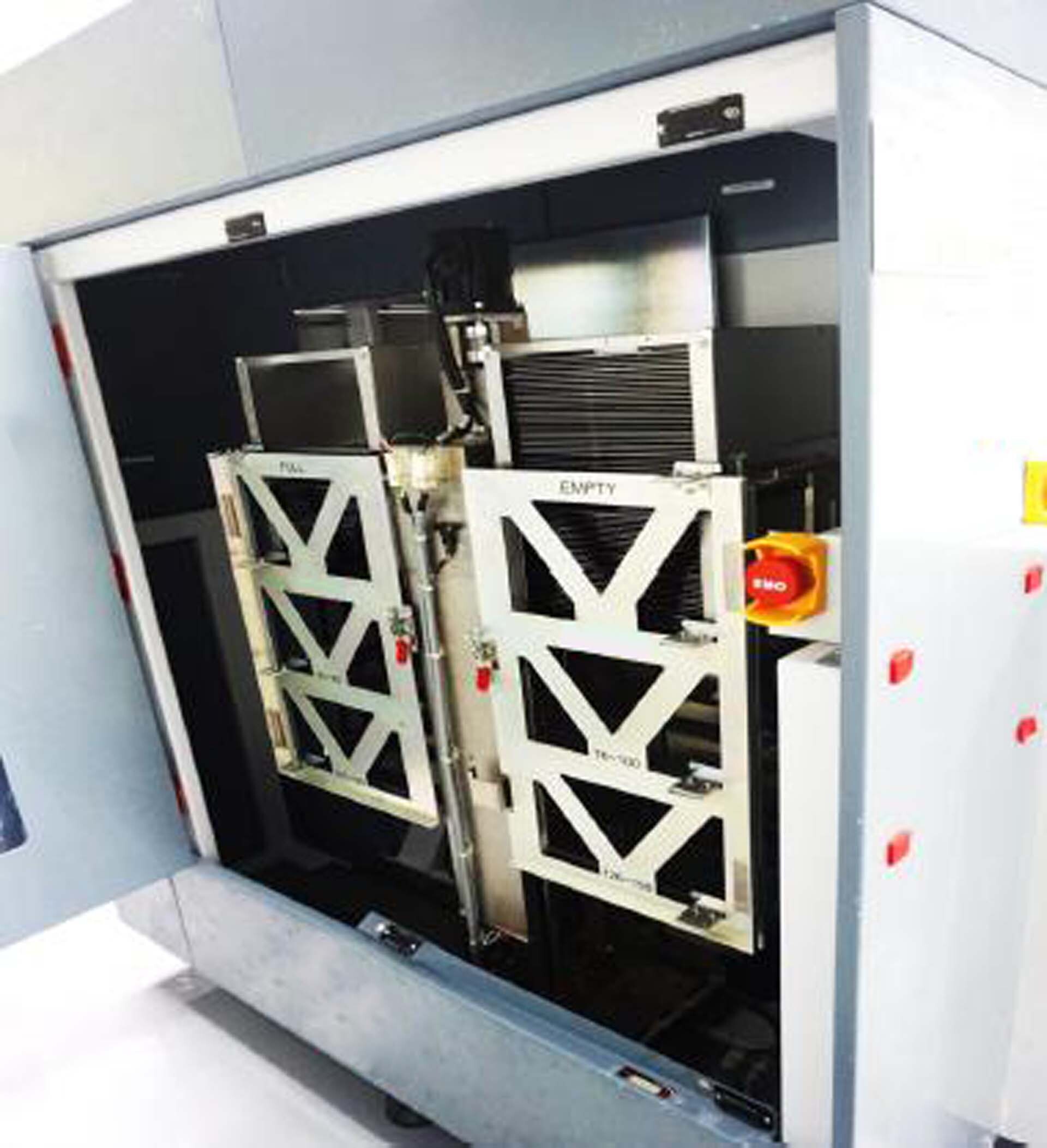

Wafer Size: 2-4"

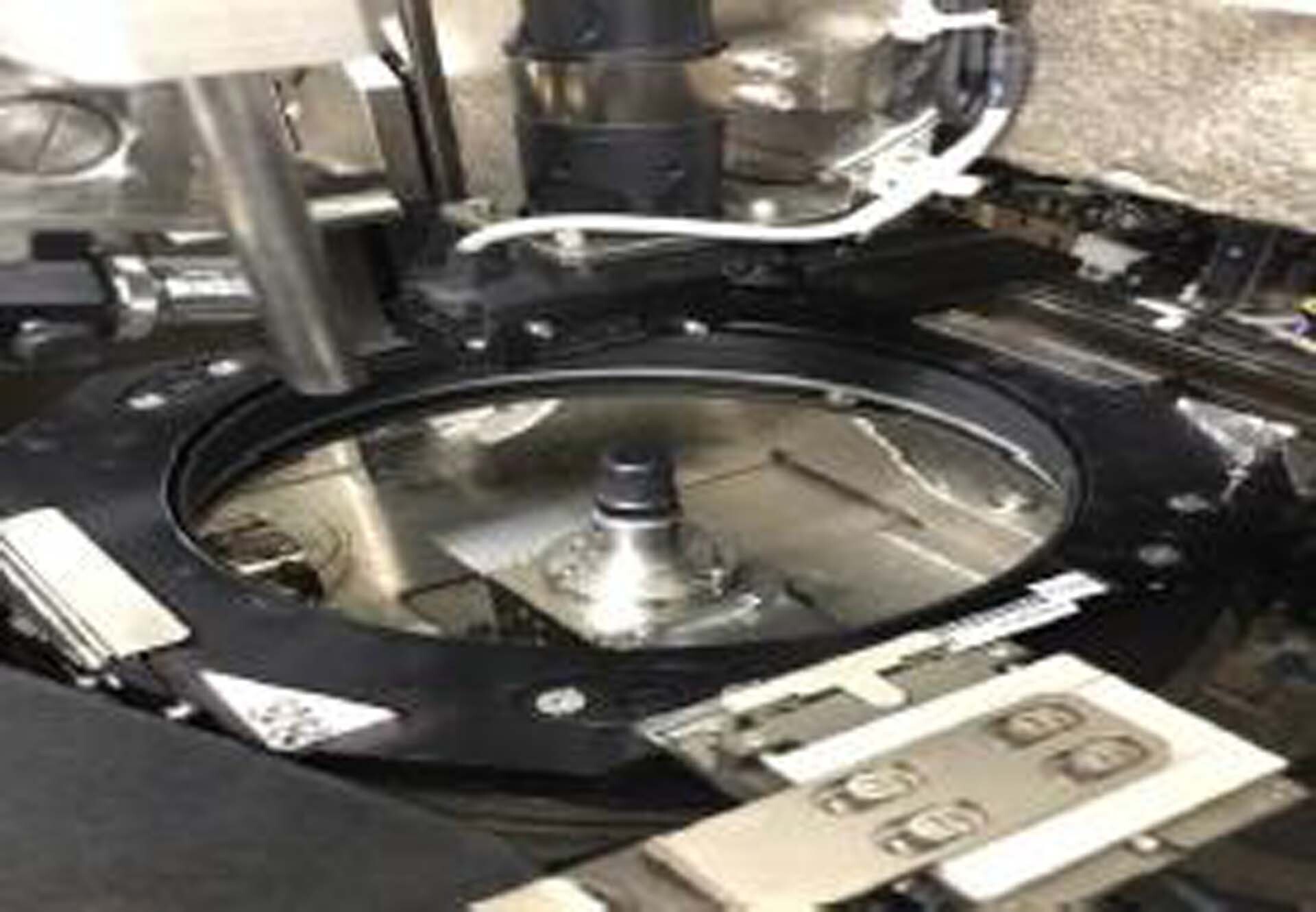

Wafer mapping die sorters, 2-4"

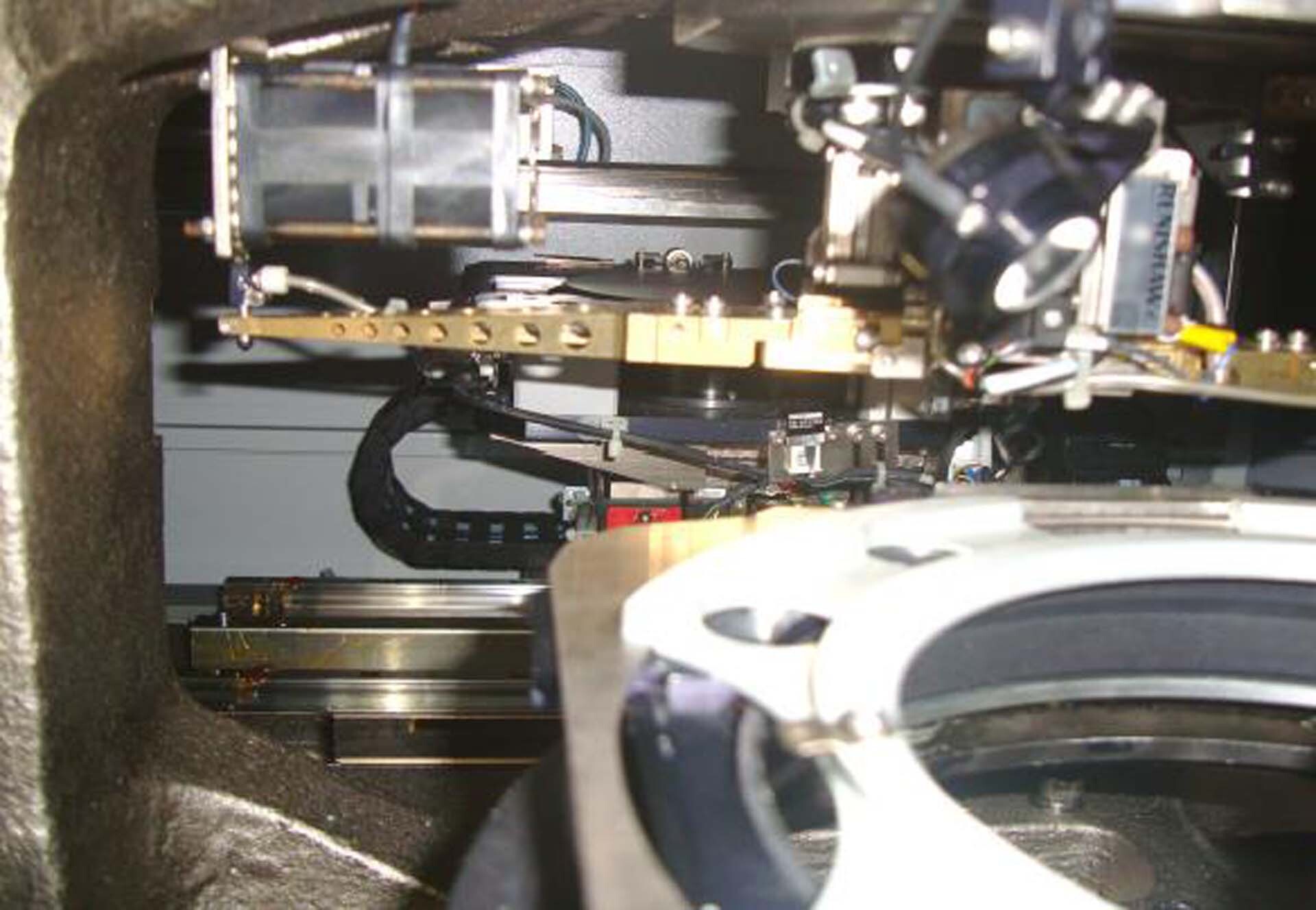

Compressed air: 87 PSI (6 bars)

Compressed air consumption: 155LPM

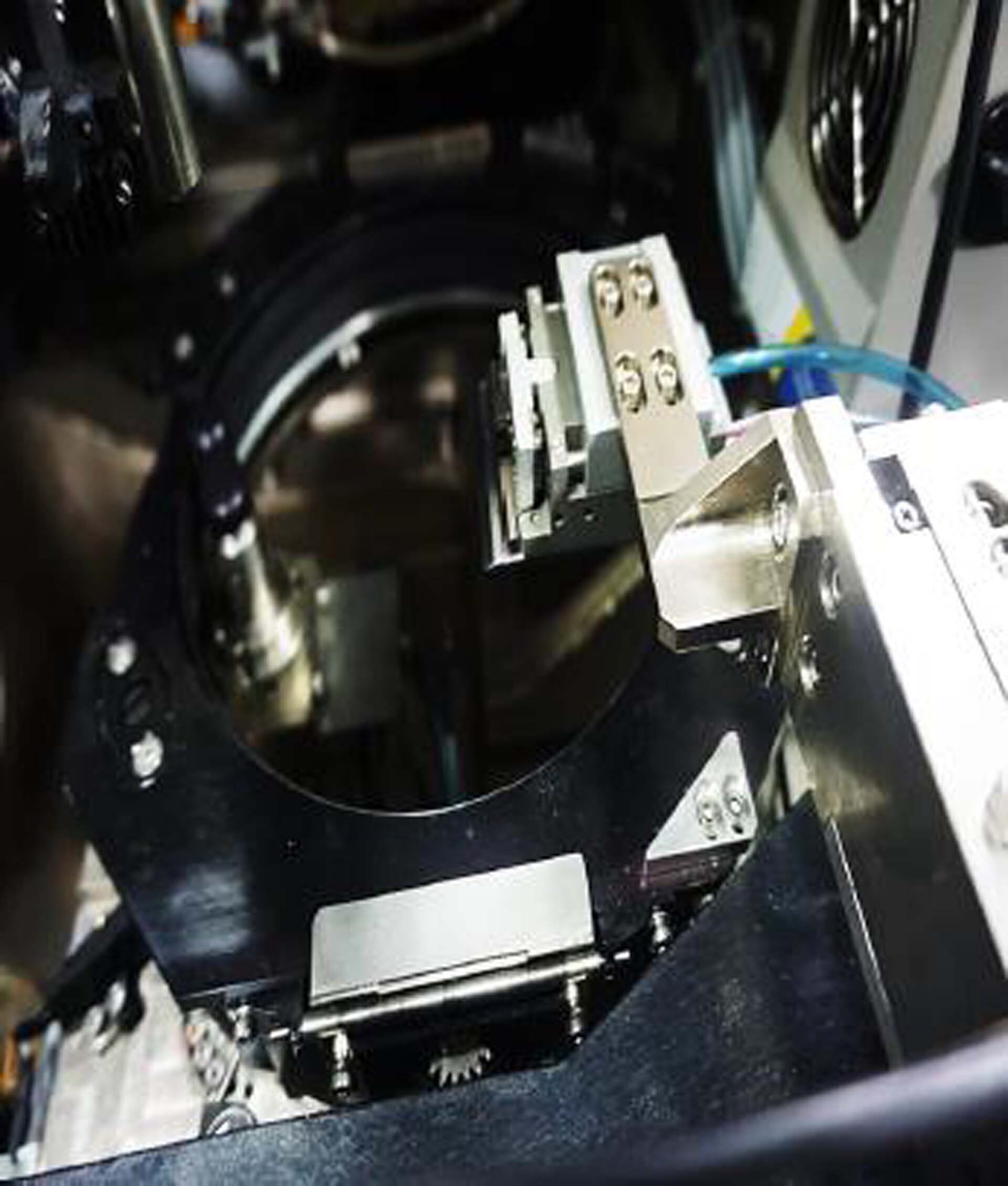

Bonding head and bonding force: 40-250g

Cycle time for map sorting: ~175 ms

Average placement accuracy: ±1 mil

Die rotation range: 1°

Power supply: 100-240 VAC, 50/60Hz

2010-2011 vintage.

ASM MS 100 is a reliable die attacher designed to conveniently and accurately attach die onto the surface of electrical components or printed circuit boards. This manual machine provides a wide range of high-quality components and features to ensure a successful and repeatable die attach process. ASM MS100 features a high-strength steel frame, which is designed to be resistant to device-level shock, vibration, and other environmental disturbances. The frame also features rubber vibration damping mounts to reduce the risk of loosening components or damaging the circuit elements being attached. The unit is equipped with two components, the die fillet dispenser and the substrate holder. The die fillet dispenser provides a uniform, consistent flow of die fillet paste, which is accurately and evenly applied to the PCB during the die attaching process. The substrate holder is responsible for providing a stable and secure platform for the PCB, which ensures a successful and repeatable die attach process. MS 100 is equipped with an intuitive LCD display and easy-to-use operator panel. This allows the operator to enter parameters into the system in order to program the dispensing and attaching parameters for each different PCB. The system also features a set of quick-change attachments for hands-free movement of the die fillet dispenser, allowing for fast and efficient job changeovers. MS100 is designed to provide a reliable and repeatable die attach process. It features an array of safety features, including a safety cover over the open PCB, a lock to keep the cover closed during operation, and a fail-safe switch which stops the operation in the event of any malfunction. It also features a two-stage heating system, which ensures that the die attach has the correct temperature and avoids excess heat damage to the PCB surface. Overall, ASM MS 100 is designed to reliably attach die onto precision electrical components or boards. It features a robust, reliable, and repeatable die attach process, along with a range of safety features and an intuitive operator panel.

There are no reviews yet