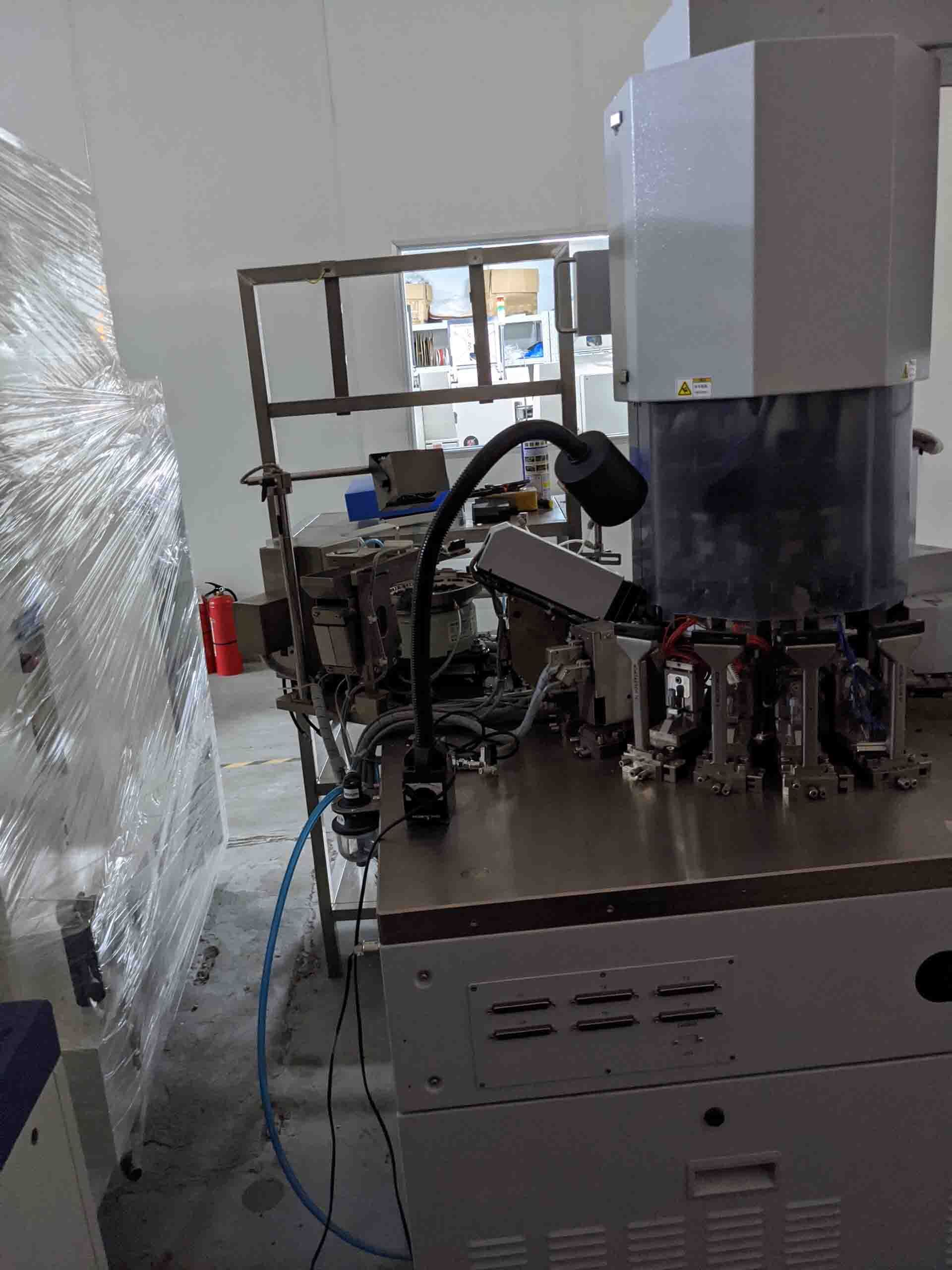

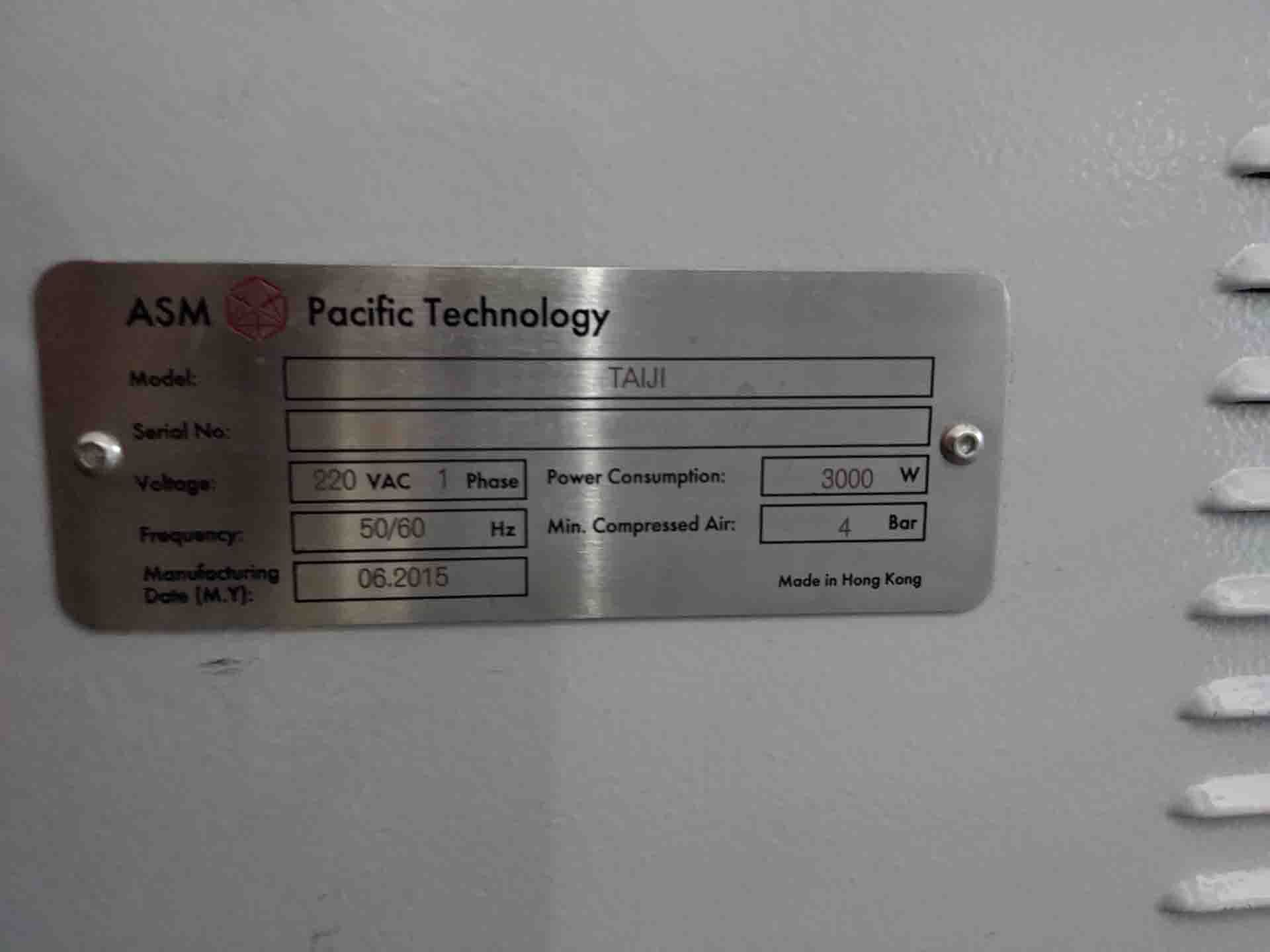

Used ASM TAIJI #293662741 for sale

URL successfully copied!

Tap to zoom

ASM TAIJI Automatic Die Attacher is an automated press feed equipment designed to increase the speed and efficiency of die attachment operations. The system includes a stable base that easily stands next to the press and a machine frame that carries the die attacher and die attachments. The machine is composed of a specialized set of mechanical, electrical, pneumatic and servo motion components that work together to provide a fully integrated die attachment solution. The press feed unit consists of an integrated vision machine, pick and place robot, die attacher, and a flexible machine guidance tool. The integrated vision asset is equipped with optics that determine the optimum location of the die to be set and determine the angle/location of the attachment points. An ultra-precise pick and place robot operates in coordination with the vision model to precisely place and align the die. The attached die is then secured with a dual die attacher operating on a six-axis servo motion control equipment, providing accurate and repeatable die attachment. TAIJI Automatic Die Attacher uses a two-step pick and place process that allows for rapid and accurate die placement. During the first step, the die is picked up and placed onto the machine table. During the second step, the rolling motion of the mechanical arm precisely positions the die at the required location and angle. The dual die attachers then move into position and secure the die onto the press. The entire process is monitored and maintained by an advanced machine guidance system, that maintains accuracy and repeatability of the unit. The machine also includes a user-friendly interface with a remote control for quick setup and monitoring of the attachment process. ASM TAIJI Automatic Die Attacher is an efficient, accurate and reliable press feed tool, and is ideal for high volume die attachment operations. This asset helps to reduce production costs and labor; increase efficiency and reduce die change-over times; and also reduces potential for human error. The advanced automation and precision of the model ensures a consistently high-quality finish for all die attachment operations.

There are no reviews yet