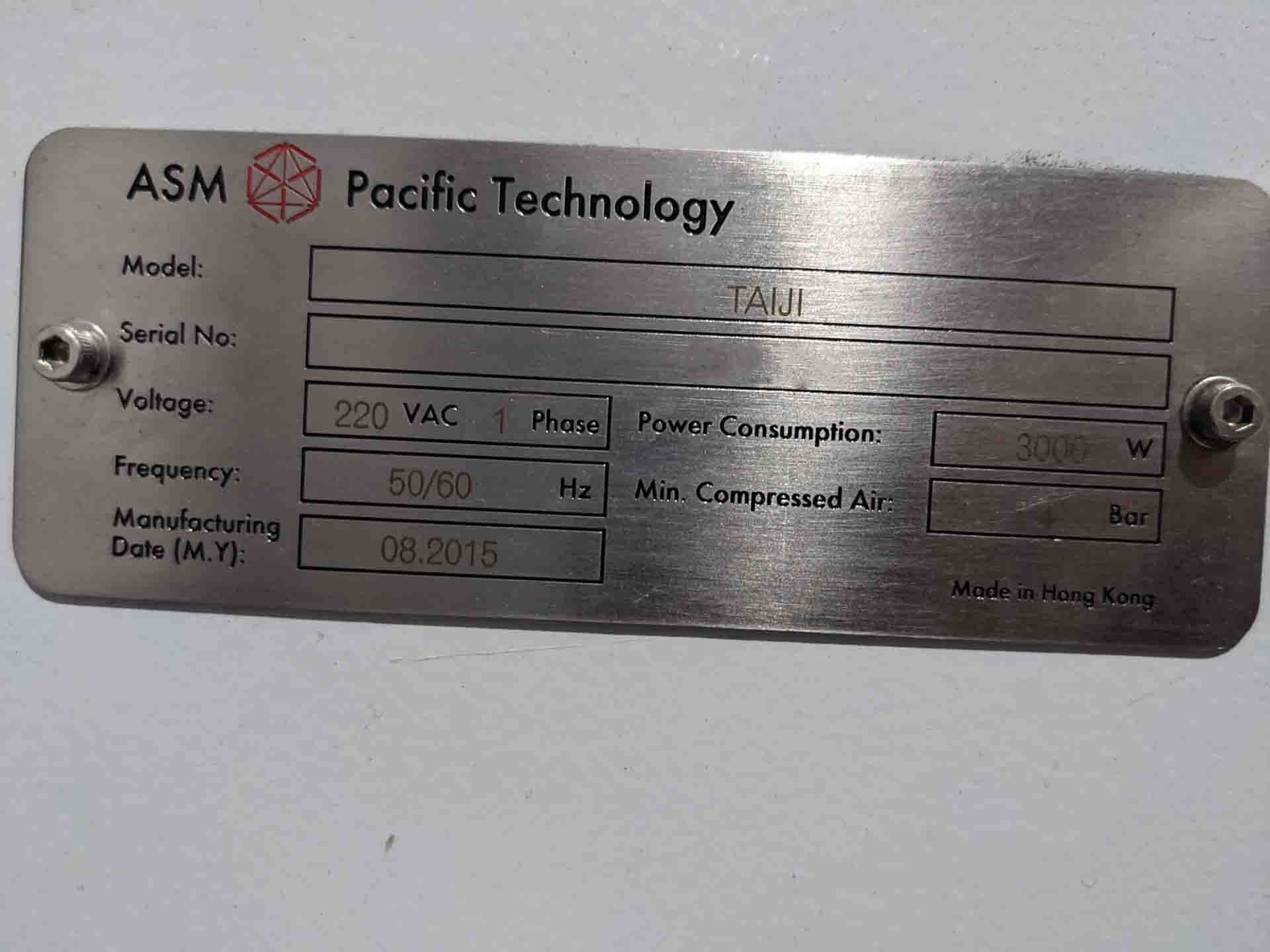

Used ASM TAIJI #293662742 for sale

URL successfully copied!

Tap to zoom

ASM TAIJI is an automated die attach machine that is used to assemble electronic components onto printed circuit boards (PCBs). The machine is capable of placing components with a pitch of 0.65mm, and can handle parts ranging from 0402 chips to 28-pin arrays. The machine has a modular design, enabling it to quickly and efficiently attach parts in a wide variety of arrangements. Its main components include a vision equipment, a nozzle system, and an automatic feeder unit. The vision machine works to detect component IDs, recognizing the part type as well as the location and orientation of the die within the part itself. The nozzle tool is used to dispense the die attach film and accurately place parts onto the board. In order to ensure the component is placed correctly with minimal deviation from the desired position, the nozzle asset is designed so as to take into account the size and shape of the PCB, as well as the placement accuracy desired. Finally, the automatic feeder model holds and feeds components into the machine for accurate placement. TAIJI provides the ability to produce high-precision assemblies and is designed for high-speed production runs. The machine is equipped with an extensive database of components that saves time by significantly reducing manual programming. Additionally, the machine can attach as many as 80 components per board, making it an ideal choice for large production runs of PCBs. The machine is also highly reliable and can be integrated into an automated line due to its software compatibility. For use in harsh working environments, ASM TAIJI has built-in air filtration systems, top and bottom camera shutters, and an integrated temperature monitoring equipment. This helps to provide the protection and quality assurance required for the automated assembly of die attach components. Overall, TAIJI is a powerful and reliable die attach machine perfect for high-speed production runs. Its modular design, built-in features, and database of components provide the necessary speed and accuracy needed to successfully produce high-precision assemblies.

There are no reviews yet