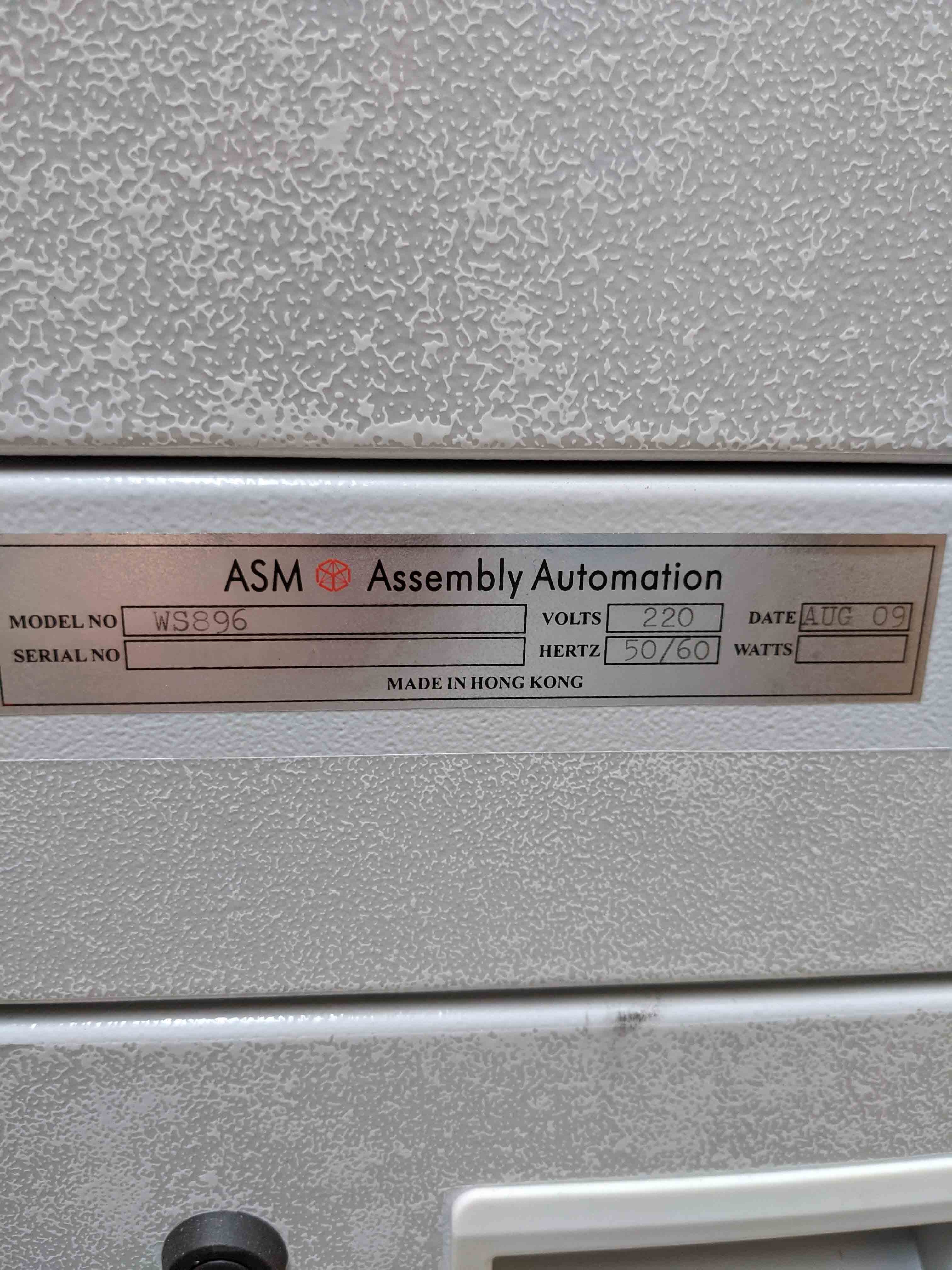

Used ASM WS 896 #9384494 for sale

URL successfully copied!

Tap to zoom

ASM WS 896 is an advanced die attacher that is designed to provide precise, reliable, and consistent die attach performance. It is built for high-volume and automated production of high-quality die packages. The equipment is equipped with a state-of-the-art die vision system. This makes it easier to handle large and complex dies, as well as appreciate multi-part packages. Additionally, ASM WS896 comes with a die temperature monitor that helps maintain optimal temperature for successful attach. The unit is capable of handling die down to 0.5mm in feature size and up to 8mm in each direction. The machine is equipped with a heavy-duty frame that can support up to 234kg and a maximum part size of 250 x 250 mm. The tool also features optimized radial symmetry and is equipped with a built-in automatic die tilt mechanism for precision alignment. WS 896 is an advanced automation platform that has been specifically designed to produce complex devices. It is equipped with a sophisticated solder dispensing asset that is capable of dispensing uniform balls of solder with an accuracy of ±10µm and a ball size down to 200µm. The model also features a high-precision, laser-based device positioning equipment that is capable of aligning die packages with a repeatability of ±10µm. Additionally, the system comes with a pre-built safety architecture that ensures optimum safety throughout the entire production process. This includes a comprehensive alarm unit, robust mechanical pushing force limiters, automatic fail-safe nozzle cleaning machine, and a low-pressure sensor with a standard valve for emergency shut-off. WS896 is one of the most advanced automation platforms available today. It provides superior die attach performance with precise alignment and uniform ball deposition. It is also designed with enhanced safety features to ensure optimum operator safety. Moreover, its reduced maintenance requirements reduce downtime and improve operational efficiency.

There are no reviews yet