Used ESC 9200 #39586 for sale

URL successfully copied!

Tap to zoom

ID: 39586

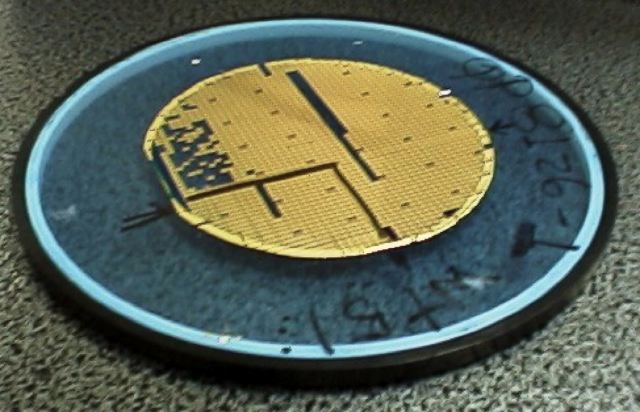

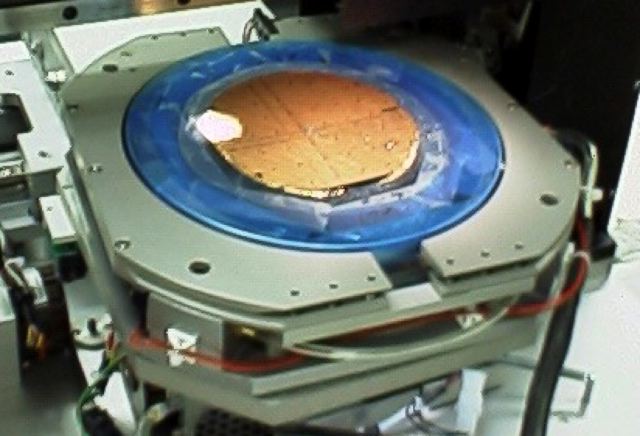

Wafer Size: 8"

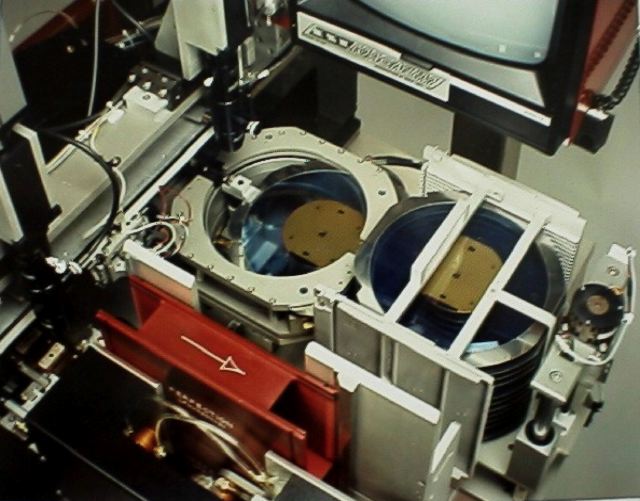

Epoxy die attach machine with Cognex vision

8" wafer with auto cassette

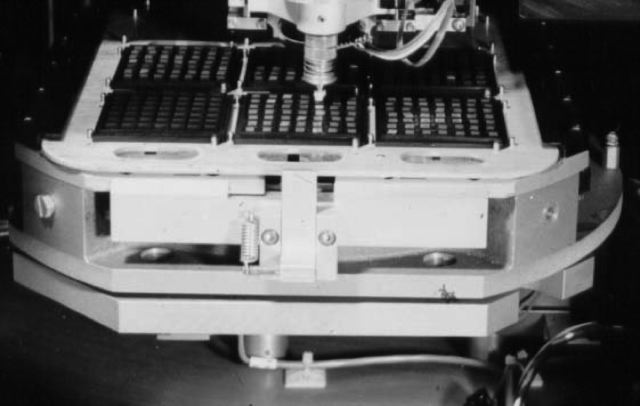

Auto indexer or 4" x 20" matrix x-y table to handle many diferent devices

Unstack to Magazine or Magazine to Magazine

Matrix Capability: Up to 8” wafer capability

Capable of picking die from wafer on film frame, wafer on rings, waffle packs, and gel packs

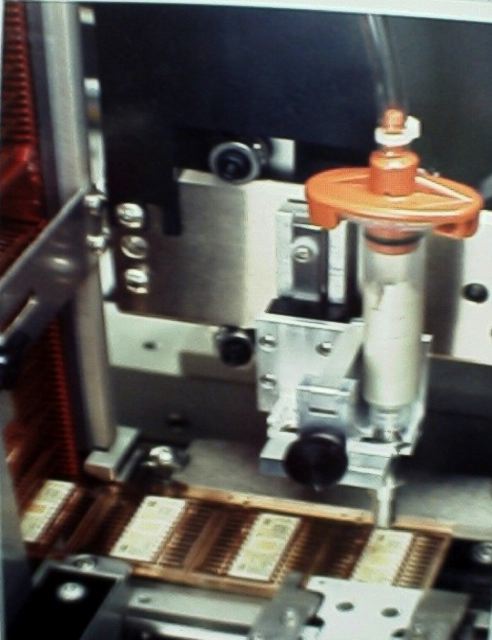

Programmable Syringe dispenser

Leadframe input: Dual unstacker with paper separator

Programmable magazine input

Programmable Gripper Indexer

Pattern Recognition System (PRS): Ink dot or broken corners to skip die

SECS/GEM compliant for wafer mapping

ALPS compatible

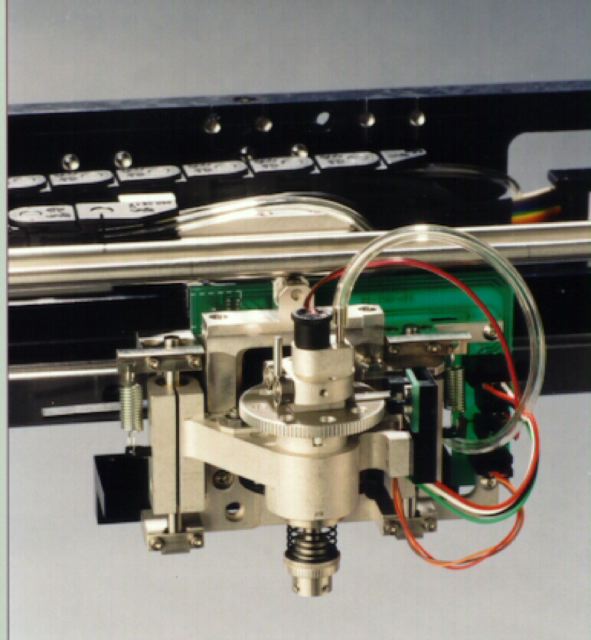

Linear Pick Bondhead

Programmable Approach Speeds

Y programmable scrub (amplitude, time and frequency)

Rotary Bondhead available

Die Presentation: Waffle / gel pack, film frame, wafer ring

Wafer Handler: Film Frame or Wafer Ring, Automatic wafer changer available

Small Footprint

Rack mounted electronics serviceable from the front

Simple Mechanisms allow easy servicing & accessibility

User friendly operator interface (via Light Pen touch screen)

Up to 100 recipes on HDD

Can be configured to your products process or as is configuration and condition

~2000 vintage.

An ESC 9200 die attacher is a machine used to secure a die to the anvil plate of a stamping press. It is specially designed for attaching high-value and high-density dies to an anvil plate. This ensures a secure connection between the press and the die, and it also helps to reduce machine downtime associated with die tray breakage, double-chucking, and die deployment errors. 9200 die attacher uses a two-stage process to securely attach a high-density die to the anvil plate. During the first stage, a vacuum is created inside a chamber beneath the die which vacuums up the metal chips. Inside the chamber is a vacuum plate which firstly applies a few drops of adhesive to the anvil plate, and secondly uses a needle wheel to move the die into position for attaching. After the initial positioning, a stepped cam mechanism moves the die into the exact position required. Once the die is fully in position, an electric nutrunner brings the die down onto the adhesive-coated anvil plate, with the necessary force applied to bring it close to the plate. Finally, the nutrunner and stepped cam are loosened, and the die is securely attached to the plate. ESC 9200 die attacher is designed for high-volume applications, with a cycle time of around 3.5 seconds to secure a high-value die to the anvil plate. The machine is also easy to use, with simple operation settings that can be changed in a matter of seconds. The entire machine is solidly built, and its components are of high quality - including the heavy-duty locking bolts to ensure the die is secure on the anvil plate. Overall, 9200 die attacher is a reliable solution for attaching a high-value and high-density die to an anvil plate. Its two-stage process is efficient, and its robust design and construction ensure reliable performance even in high-volume environments.

There are no reviews yet