Used ESC Magnum #9225561 for sale

URL successfully copied!

Tap to zoom

ID: 9225561

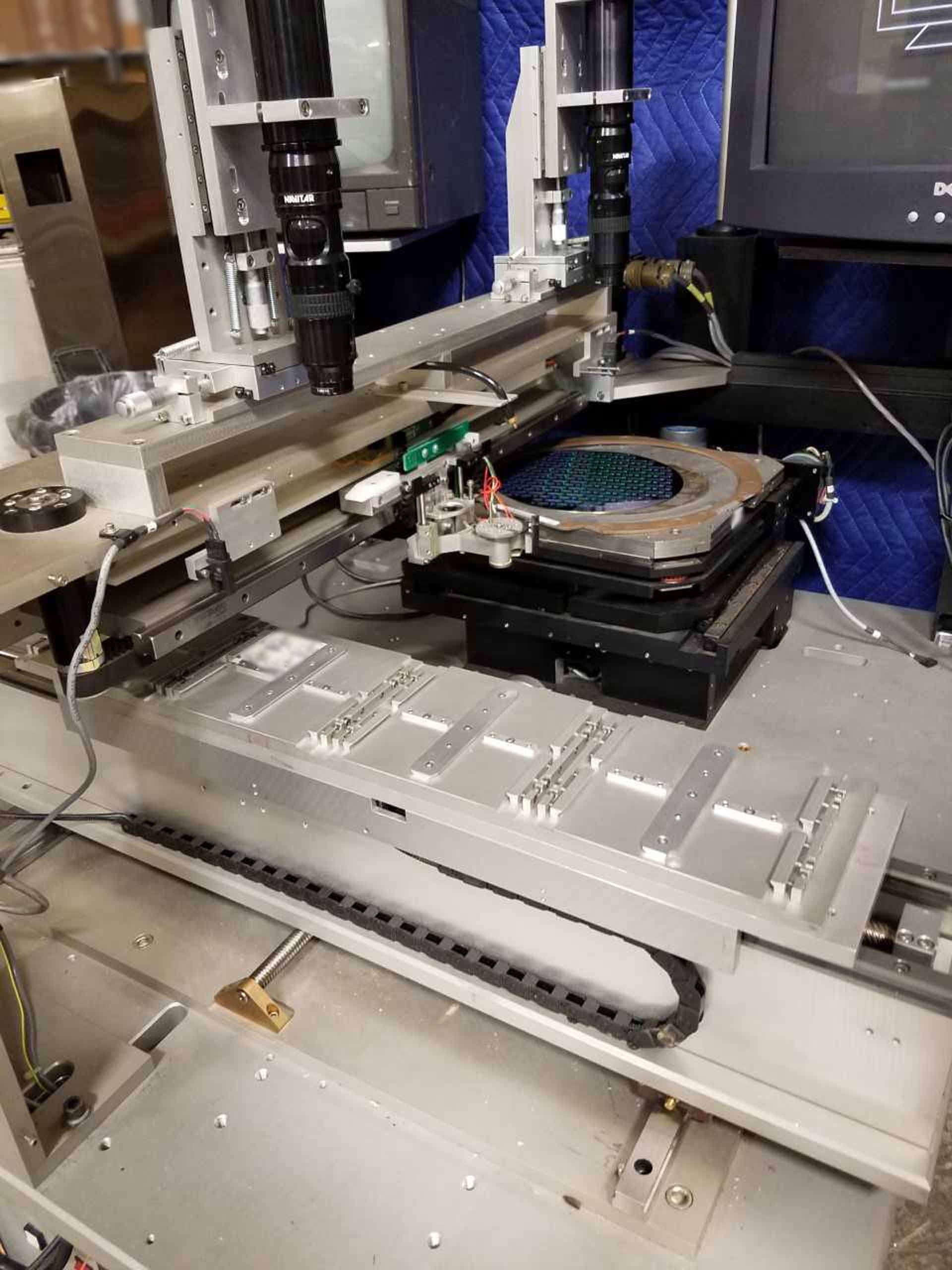

Wafer Size: 8"

Die sorter, 8"

Input process materials:

Die size / Thickness: 0.18 - 12.7 mm x 0.254 - 2.54 mm

Waffle / Gel packs: X-Y Table handles 2x2" / 4x4" Waffle pack adapter

Tape input: Single & multi-tape

Applications ranging: 15 mm - 60 mm (Wide)

Foton rings: 125 mm - 200 mm

Die ejector:

Drive system:

Dual step eject motion with programmable dwell time

Anvil: Vacuum hold down (Tool-less changeover)

Ejector: Single / Multiple needle (Tool-less changeover)

Output materials:

Film frame: Up to 200 mm wafers round / Square array

Waffle / Gel packs

Manual load / Unload: 2x2" / 4x4" Chip tray adapters

JEDEC Trays: Manual load / Unload

Tape output: Single & multi-tape

Applications ranging: 15 - 60 mm (Wide)

Output process:

Work holder: 101.6 mm x 508 mm

Programmable pitch: Single pass & multi-pass die placement

Wafer table:

Capable of processing: Up to 200 mm wafers

JEDEC Assembly: Positions & handles JEDEC trays

Interface:

Monitor: 13” VGA Monitor (Vision display)

Programming: 13” Color VGA touch screen operator interface

Recipe storage: Minimum 100 recipes on HDD & 3.5” floppy disk

COM Port: RS232 Up to 9600 baud SECS I & II, GEM compliant

Optical recognition system:

Accuracy: +/-1 Pixel

Resolution: 256 Grey level at 640 x 480 pixels

Capabilities:

Pre-pick & place alignment with inked

Chipped

Edge

Inspection tools

Post bond inspection tools: Surface analysis & position data

Placement accuracy:

X / Y Theta: +/- 50µm X / Y, 3° Theta

System throughput:

Typical cycle rate: 4200 Placements / Hour

Facilities:

Air: 100 PSI

Vacuum: 22” Hg

Options:

Rotary bond head: Gear driven 0 - 360°

Wafer mapping: RS-232 Host link with input & output bar code reader

Auto wafer handling: Up to 200 mm wafers mounted on film frames

Tape & reel output: Custom design (Single & multi-reel applications)

Power: 110/208/220 VAC, Single phase, 15 amps, 50/60 Hz.

ESC Magnum is a professional-grade die attacher used to attach tapered and cylindrical dies to a variety of die areas. The machine is designed to produce die-attachment quality that exceeds even the highest industrial standards, and features a patented infrared heating equipment that ensures smooth, accurate, and consistent results. Magnum is capable of attaching up to four dies to each surface simultaneously. The ergonomic design is ideal for ergonomic use, ensuring that the attacher reaches all difficult-to-reach dies. The machine is easy to operate, with visual guides that help the user accurately align the die areas and staple guides that accurately guide and control the die insertion force. ESC Magnum features an advanced die-attachment mechanism, which works by gripping the die and securely fixing it to the area. The die-attachment mechanism also has a linear screw guide, which allows precise alignment and calibration of the dies. The die size is controlled individually based on the settings of the die-attachment mechanism. Magnum also comes with an electronic temperature control system, which monitors and increases the temperature of the dies continuously until the optimal temperature is reached. The machine also features a high-grade metal frame that offers consistent and repeatable results, and is designed to be durable and reliable. Finally, ESC Magnum is also equipped with a built-in cooling unit and a built-in dust removal machine. The cooling tool ensures a longer life of the dies, while the dust removal asset ensures that the working area is well maintained and clean. The dust removal model can also be manually activated or set to automatic mode.

There are no reviews yet