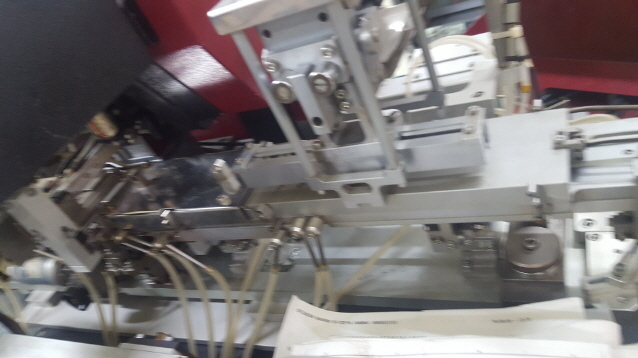

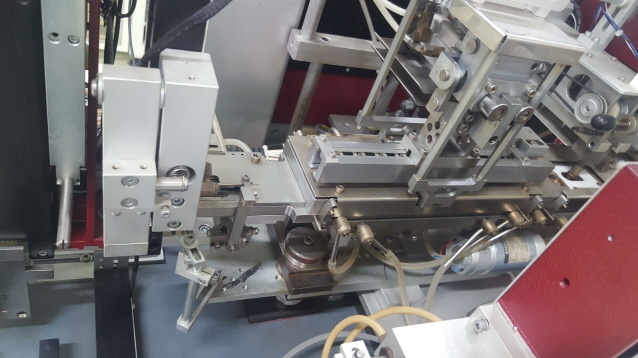

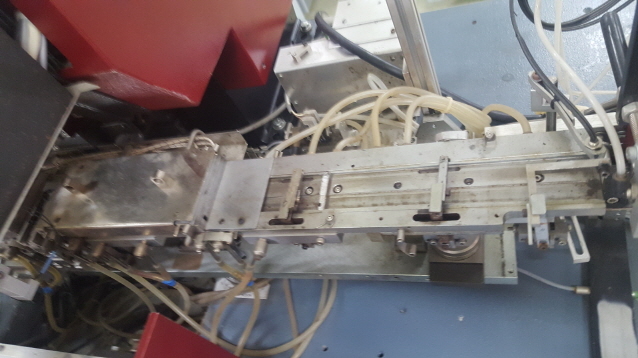

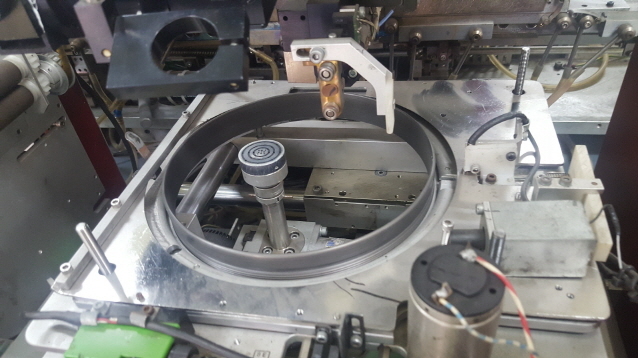

Used ESEC 2005 HR #128622 for sale

URL successfully copied!

Tap to zoom

ID: 128622

Wafer Size: 6"

Vintage: 1998

APLF Soft solder bonder, 6"

D2-Pack

Die placement accuracy: +/- 25 um

With die-collet and scrub

Cycle time: 0.5s

Cycle speed: 7200 CPH

Bond time prebond and postbond: 0 - 3000 ms

X-Direction scrub programmable parameters:

Amplitude: up to +/- 1 mm

Frequency: 0 - 50 Hz

Number of cycles: 0 - 100

Offset: +/- 0.25 mm

Minimum die size: 0.20 mm x 0.20 mm

Maximum die size: 15.0 mm x 15.0 mm

(1) Zoom-lens

Magnification ratio: 1:6.5

Typical productivity: 3500 to 4500 UPH

Foil expansion: Adjustable, up to 30 mm in each direction

Alignment time for die size:

90 ms for 0.6 mm

170 ms for 6.0 mm

Corner detection:

Programmable from: -20% to +5%

Windows for all four corners

Inkdot recognition:

Rectangular window

Size, position, and sensitivity programmable

Furnace: (8) Digitally controlled heating zones with multiple heating elements

Facilities:

220V +10%/-15%, 50/60 Hz, 3.5 kW peak (heat up)

Compressed air: 4 - 5 bar (58 - 87 PSI)

Nitrogen / Forming gas: 18 - 3 bar (26 - 43 PSI)

Vacuum: Minimum -0.7 bar

Water (if applicable): 2 - 3 bar (29 - 43 PSI)

1998 vintage.

ESEC 2005 HR is a die attacher used to secure dice to a substrate. It uses industrial-grade materials and is built with high-quality engineering standards which make it suitable for use in a variety of applications. ESEC 2005HR's housing consists of aluminum and utilizes a pneumatically operated die mechanism for attaching. It has a large working area to accommodate various sizes of dice, and its patented quick change die holder reduces downtime and streamlines the changeover process. 2005 HR uses a vacuum-operated nozzle to secure the die onto the substrate. When the vacuum is activated, a negative pressure is created, allowing the die holder to attach securely to the substrate. The die is then released and vacuumed away from the substrate, securing the die. This process ensures the die is securely affixed to the substrate without compromising the precision of the die holder. 2005HR is designed with a robust construction to withstand extreme temperatures and is made to operate at high speeds, up to 215 cycles per minute and even higher with an optional kit. This ensures the accuracy and reliability of the die attachment process as well as providing superior resistance to vibrations. ESEC 2005 HR's advanced software gives users access to a variety of features such as monitoring, controlling, and programming the machine. This allows users to easily customize the machine to their specific application, providing them maximum flexibility to meet their requirements. ESEC 2005HR is also available with safety features such as an emergency stop, a safety fence, and an air blast option. These safety features help ensure the safety of the operator and the machine, while still providing maximum efficiency. Overall, 2005 HR is an advanced and reliable die attacher which is designed to attach dice to various substrates. It's built with high-quality engineering standards and incorporates the latest safety technologies, making it suitable for use in a variety of applications.

There are no reviews yet