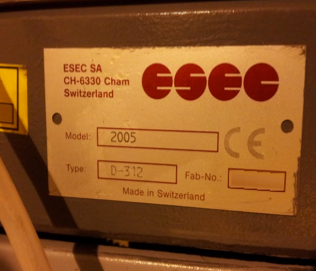

Used ESEC 2005 HR #9081721 for sale

URL successfully copied!

Tap to zoom

ESEC 2005 HR is a die attacher developed by ESEC Systems Inc, a leading innovator in the die attachment market. ESEC 2005HR is designed for high-volume production of a variety of components, including semiconductors, transistors, and other products requiring high adhesion and heat resistance. The attacher helps to ensure that components are properly aligned and held in place during machine operations. 2005 HR is a two-station die attacher that features a dual-head, quick-change equipment and a pulse-heating system. Both heads can be adjusted from either the front or the back for greater flexibility. The heads also feature locking latch devices and brakes to hold the die in place during processing. The attacher also offers an adjustable z-axis to ensure the accuracy of each die placement. The heart of 2005HR is ESEC innovative pulse-heating unit, which uses a high-precision, pulse-width controller to deliver consistent energy to the die. This ensures that the temperatures remain within the bounds necessary for proper heat resistance and adhesion of components. The attacher also utilizes ESEC patented air-flow machine to dissipate heat away so that components aren't damaged due to excessive temperatures. ESEC 2005 HR is designed to handle both different die types, as well as a variety of component sizes, from small to large. The attacher is also highly efficient, with fast cycle times and an automated production process that can handle multiple parts at the same time. This makes it a great choice for mass production of objects requiring precise die attachment. In addition to its robust die attachment capabilities, ESEC 2005HR also features safety measures to protect the operator and equipment from potential harm. These measures include on-board sensors that can detect problems with the equipment, as well as an automated shut-off tool should something go wrong. The attacher also utilizes extra-thick steel plating to protect components from being damaged, as well as double-sided insulation to keep circuits from shorting out. Overall, 2005 HR is an excellent choice for high-volume production of components that require high adhesion and heat resistance. The pulse-heating asset, adjustable z-axis, air-flow model, and other features all combine to make the attacher easy to use and efficient. The safety measures also ensure that no one or nothing are ever in danger during the course of operations. All of these features make 2005HR a great choice for anyone looking to automate their component production process.

There are no reviews yet