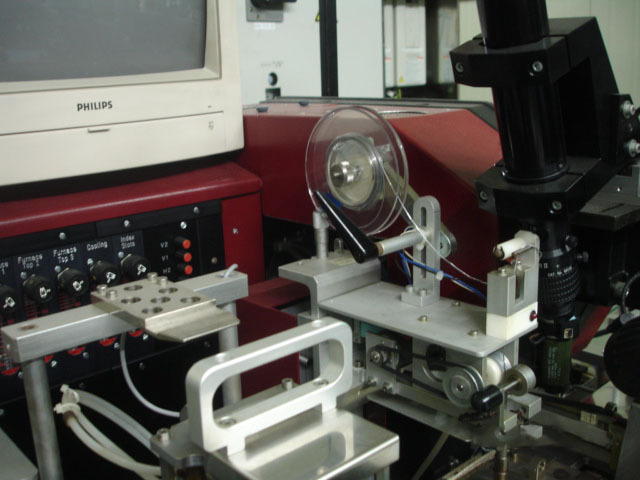

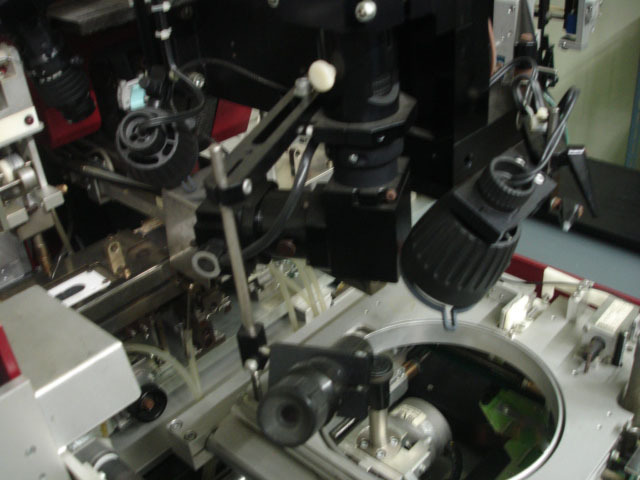

Used ESEC 2005 #128633 for sale

URL successfully copied!

Tap to zoom

ID: 128633

Wafer Size: 6"

Vintage: 1998

APLF Soft solder bonder, 6"

T0220

Die placement accuracy: +/- 25 um

With die-collet and scrub

Cycle time: 0.5s

Cycle speed: 7200 CPH

Bond time prebond and postbond: 0 - 3000 ms

X-Direction scrub programmable parameters:

Amplitude: Up to +/- 1 mm

Frequency: 0 - 50 Hz

Number of cycles: 0 - 100

Offset: +/- 0.25 mm

Minimum die size: 0.20 mm x 0.20 mm

Maximum die size: 15.0 mm x 15.0 mm

(1) Zoom-lens

Magnification ratio: 1:6.5

Typical productivity: 3500 - 4500 UPH

(TO-220 Ni-plated / bare copper / J-alloy wire preform)

Foil expansion: Adjustable, up to 30 mm in each direction

Alignment time for die size:

90 ms for 0.6 mm

170 ms for 6.0 mm

Corner detection:

Programmable from -20% to +5%

Windows for all four corners

Inkdot recognition:

Rectangular window

Size, position, and sensitivity programmable

Furnace: (8) Digitally controlled heating zones with multiple heating elements

Facilities:

220V +10%/-15%, 50/60 Hz, 3.5 kW peak (heat up)

Compressed air: 4 - 5 bar (58 - 87 PSI)

Nitrogen / Forming gas: 18 - 3 bar (26 to 43 PSI)

Vacuum: Minimum -0.7 bar

Water (if applicable): 2 - 3 bar (29 - 43 PSI)

Currently warehoused

1998 vintage.

ESEC 2005 is a die attacher that provides reliable and robust attachment of dies to printed circuit boards (PCBs). The device is capable of operating with non-contact attachment techniques, providing good visibility, precise placement, and repeatable attachment with no operator intervention, thereby removing potential errors from the process. This machine features a motor driven, modular die holder that can support a wide range of die sizes. A X-Yworktable, with a two-sided rail, provides precise placement and easy loading of the dies. The automated equipment then uses a vacuum feeder to pick up the die and feed it into the main die attacher. Upon achieving the programmed coordinates, a lower end pressure is applied to the die by the vacuum suction. The suction can also be adjusted to a higher tension when treating small dies to insure accurate attachment. The lower end pressure is then released and a higher end pressure is applied, followed by two ultrasonic welding pulses provided by a dual-head ultrasonic generator. This method of attachment creates a reliable connection with no damage to the die or PCB. The machine features automatic monitoring for die placement and attachment, as well as an adjustable motion cycle time. Its advanced control system, with Ethernet connectivity, enables integration into automated PCB assembly operations. The machine's inspection unit also allows quality control of the die attachment process by verifying the presence, position, shape, size, and orientation of each die on the board. In addition to its high accuracy and efficiency, 2005 also offers superior safety standards. The safety machine is designed with sensors to eliminate any mis-firing and provides a secure area around the machine to protect operators. The machine features built-in safety features, such as an emergency stop button and illuminated safety screens and covers. ESEC 2005 die attacher offers a reliable, accurate, and safe solution for die attachment to your assembly lines. Its superior performance and robust design provides maximum benefits and an efficient work flow, making it an ideal choice for any PCB processing needs.

There are no reviews yet