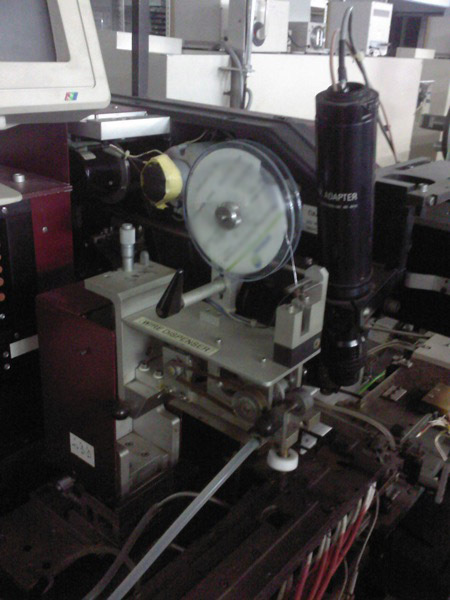

Used ESEC 2005 #161002 for sale

URL successfully copied!

Tap to zoom

ESEC 2005 is a die attacher designed for use in semiconductor production. It uses a patented Electrostatic Bonding process to attach dies to substrates. The attach process is initiated when a charge is applied to the substrate and die, creating a strong bond between the two. The die attach process is done using a single-step, multi-die process so that production requires minimal operator intervention. The machine offers high accuracy, repeatability, and speed, enabling a high throughput of up to 200cph. The machine uses a unique programmable logic and computer-controlled robotics to accurately position the die for attachment. A die pick-and-place arm is used to position the dies, and a robotic arm is used to pick up and place the substrate for attachment. The equipment also includes a stereoscopic vision system to measure the position, orientation, and size of the die during placement. The vision unit is capable of differentiating between different die sizes, allowing for high accuracy in die placement. The machine comes with a robotic die-handling station, with auto-loaders, vacuum feeders, and a variety of different jigs and fixtures. This gives the machine the flexibility to handle different die sizes and dimensions. The die handling station allows for quick and easy loading and unloading of dies, and the machine can be set to run in single-slot or dual-slot mode, for highest efficiency. The machine is also easily programmable and upgradable, allowing for easy production scalability and long-term performance. In terms of safety, 2005 is compliant with international safety protocols. It offers multiple safety features, including an ergonomic, easy-to-access safety machine and a multiple lock tool that prevents accidental machine activation. The machine also features a series of alarms as part of its error detection and prevention asset. To ensure quality and reliability, ESEC 2005 is compliant with the industry-standard ISO certified ESD standards and has been tested extensively in an array of environmental conditions. The machine also offers high built-in diagnostics and troubleshooting capabilities. 2005 is designed to meet the exacting needs of the semiconductor industry and offers a highly efficient and reliable solution for die attach production. Its accuracy, speed, repeatability, and robust safety features make it an attractive option for many semiconductor manufacturing companies.

There are no reviews yet