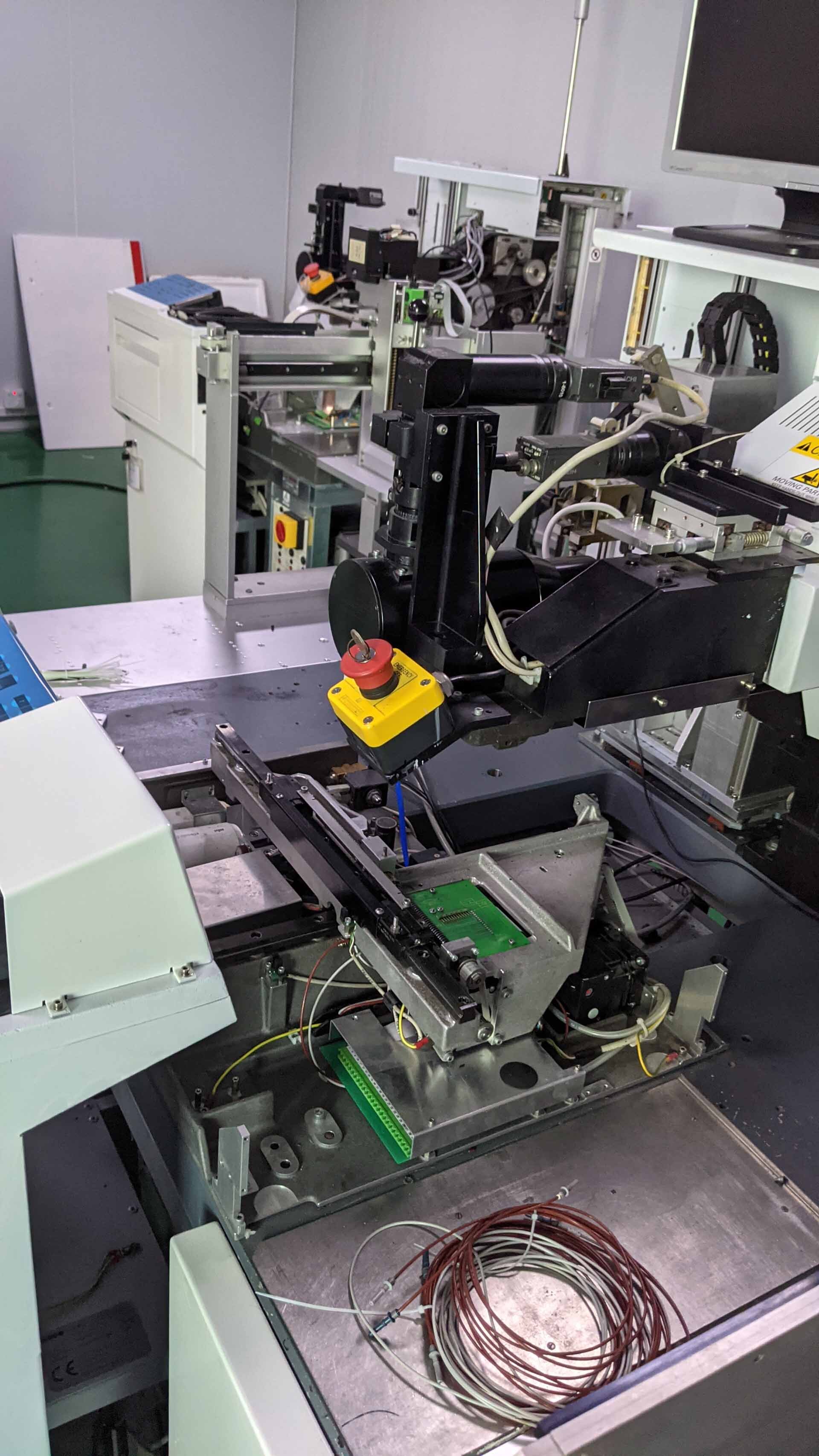

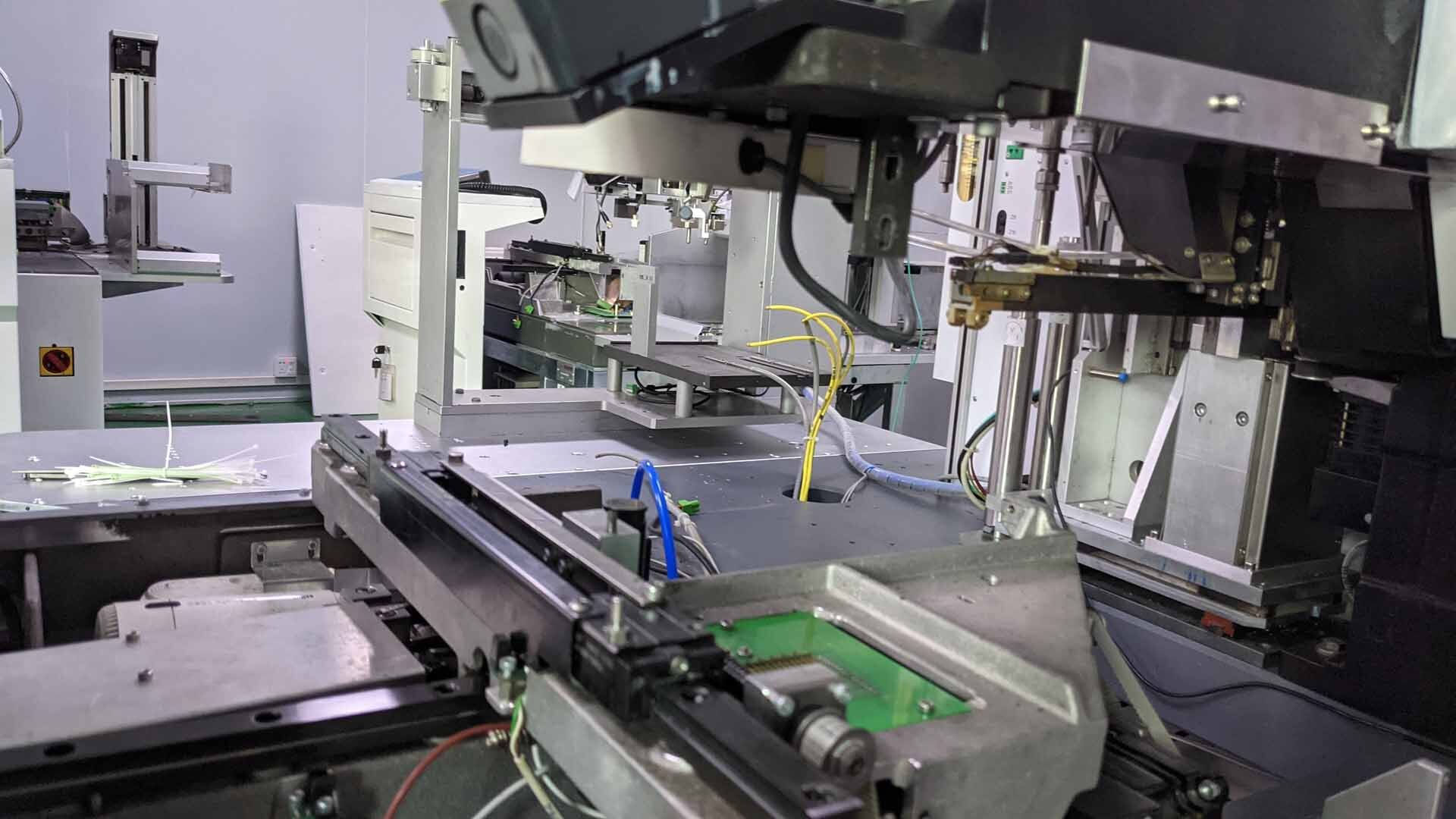

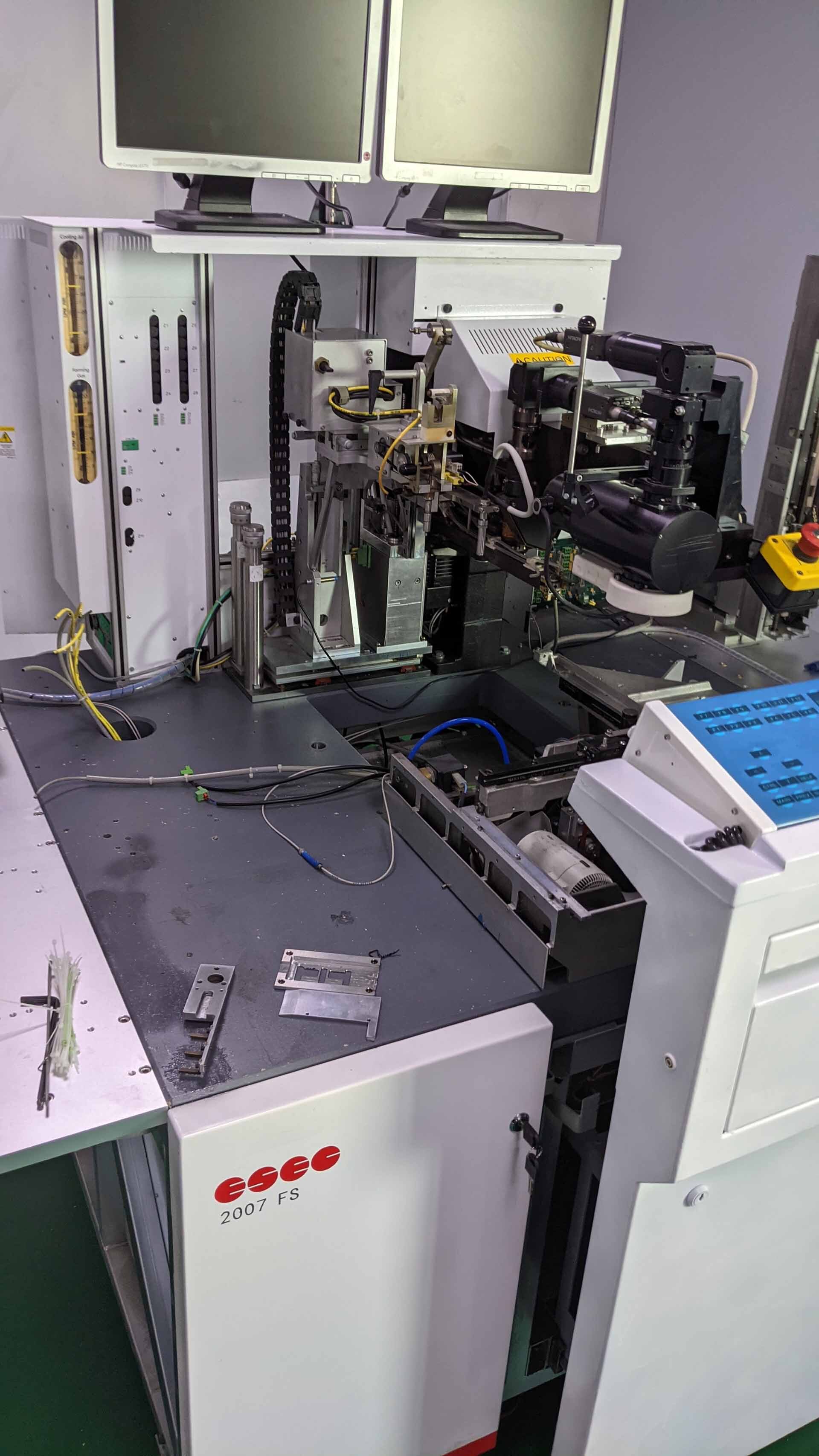

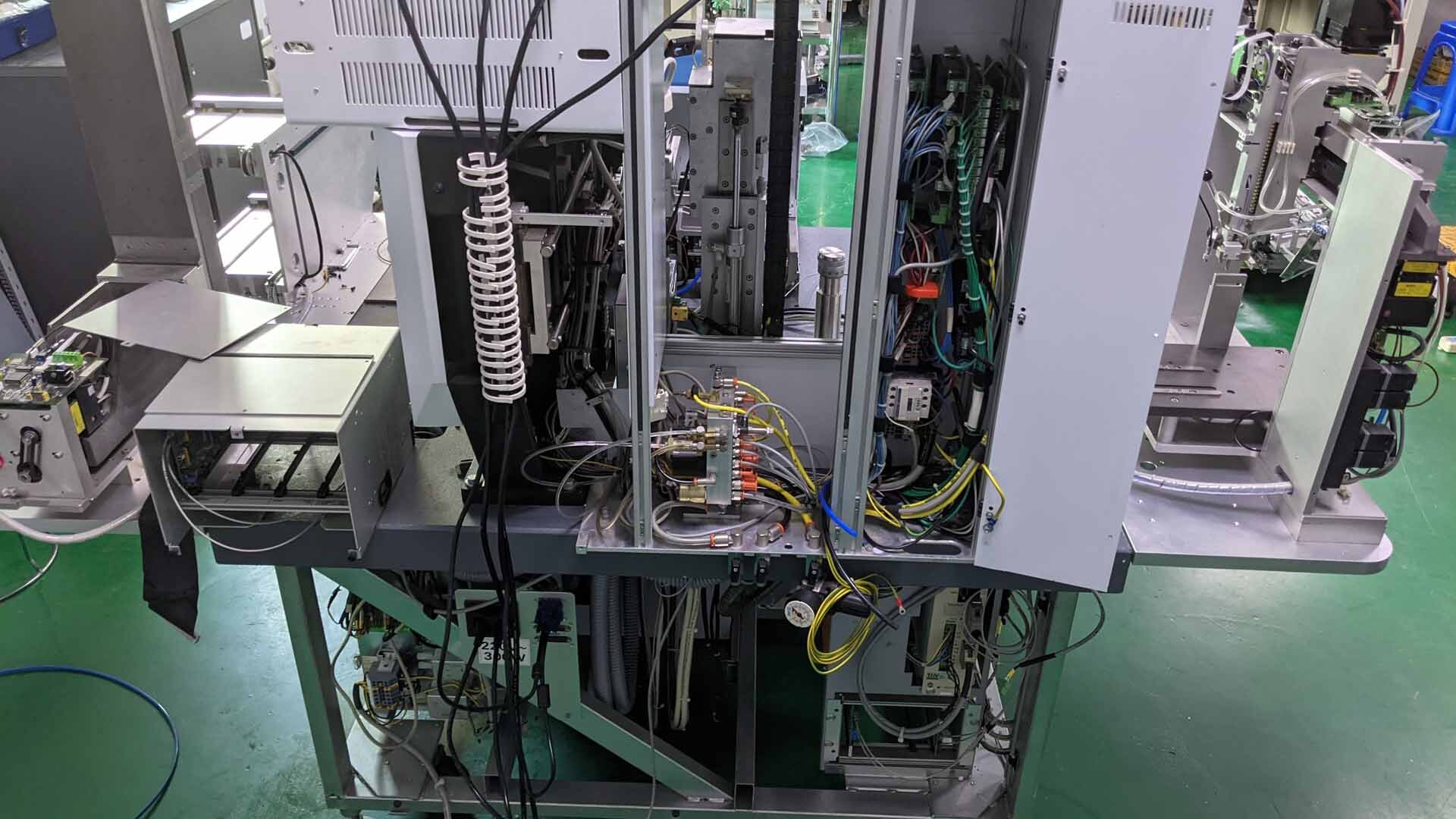

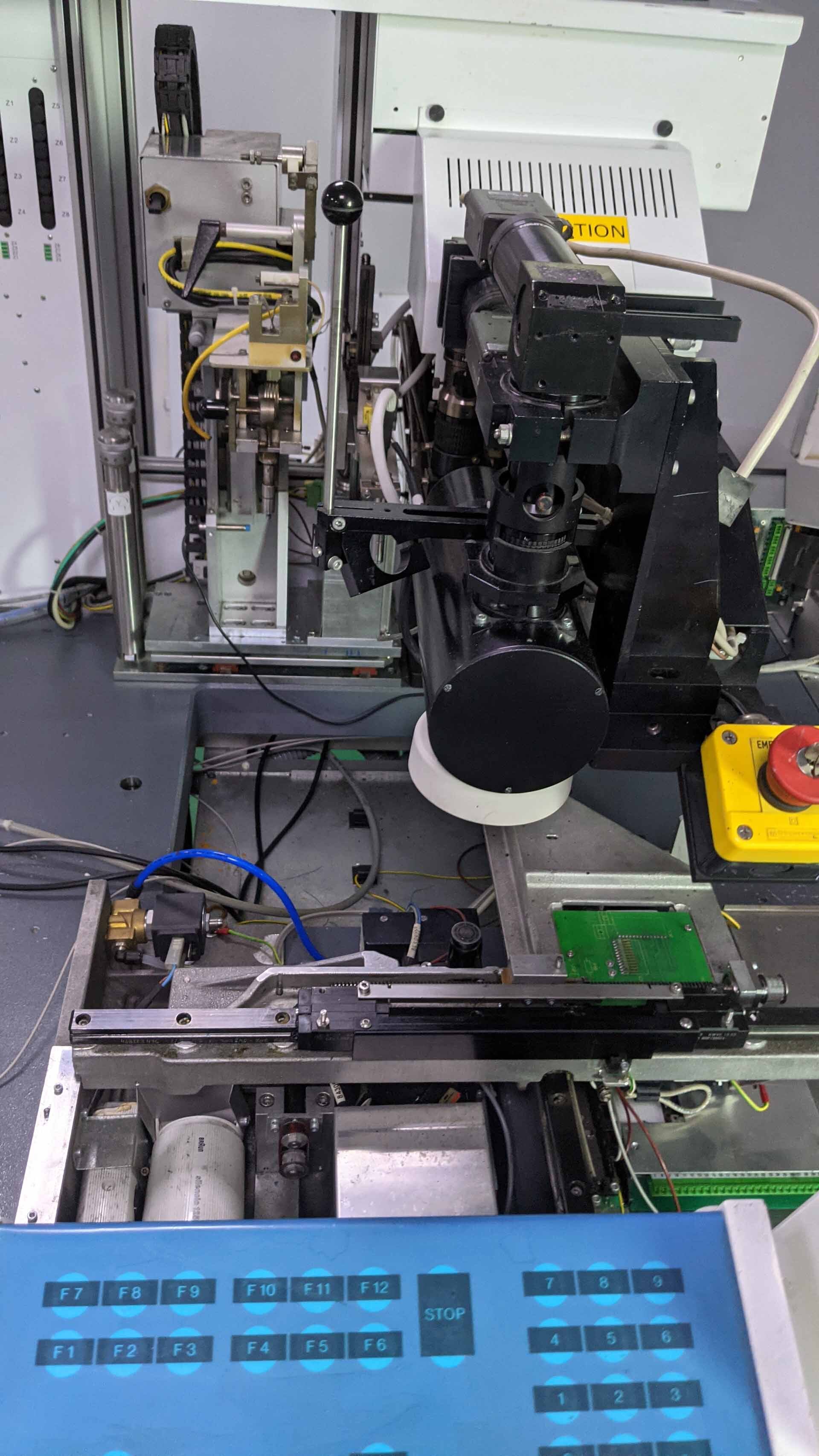

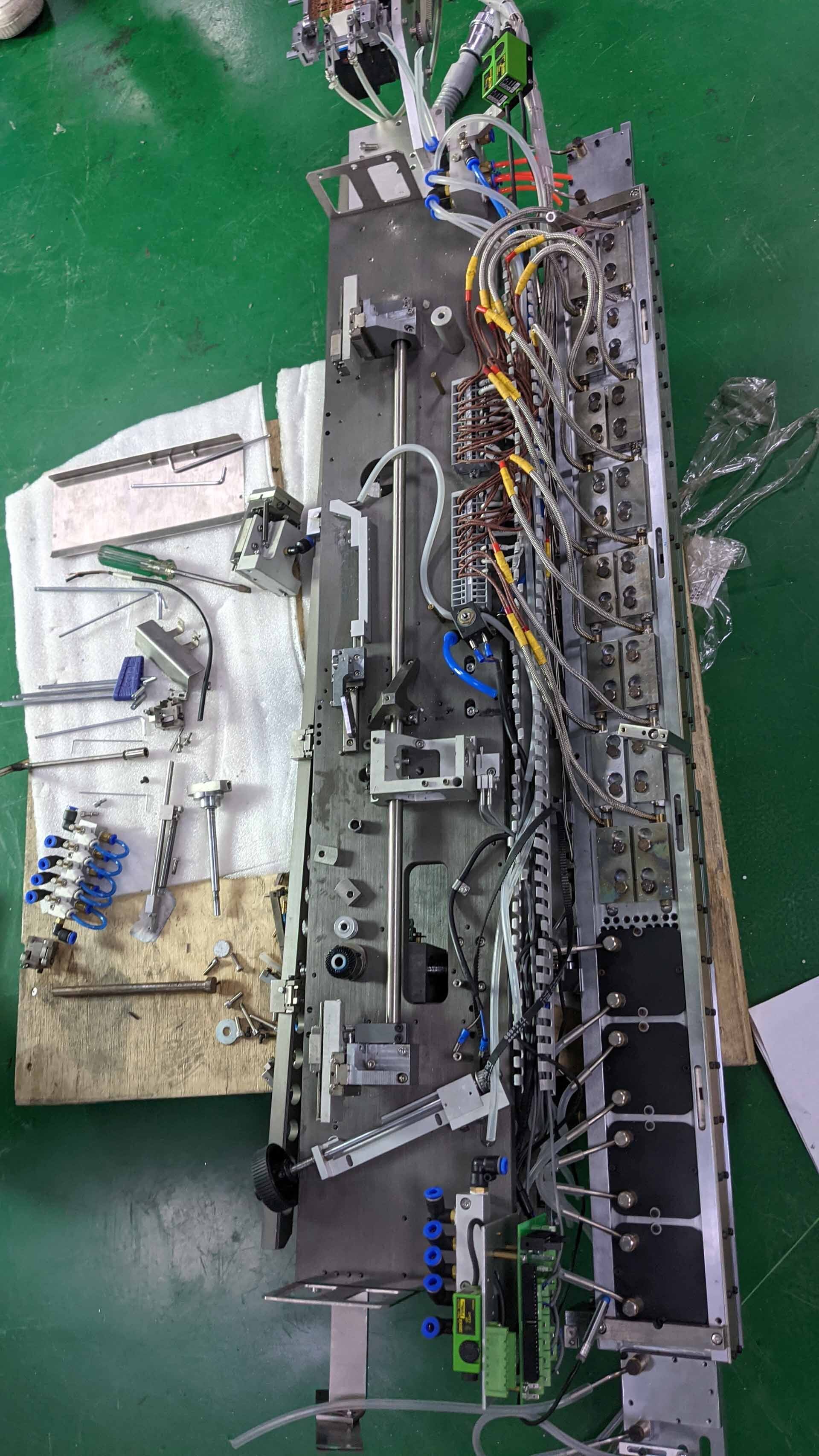

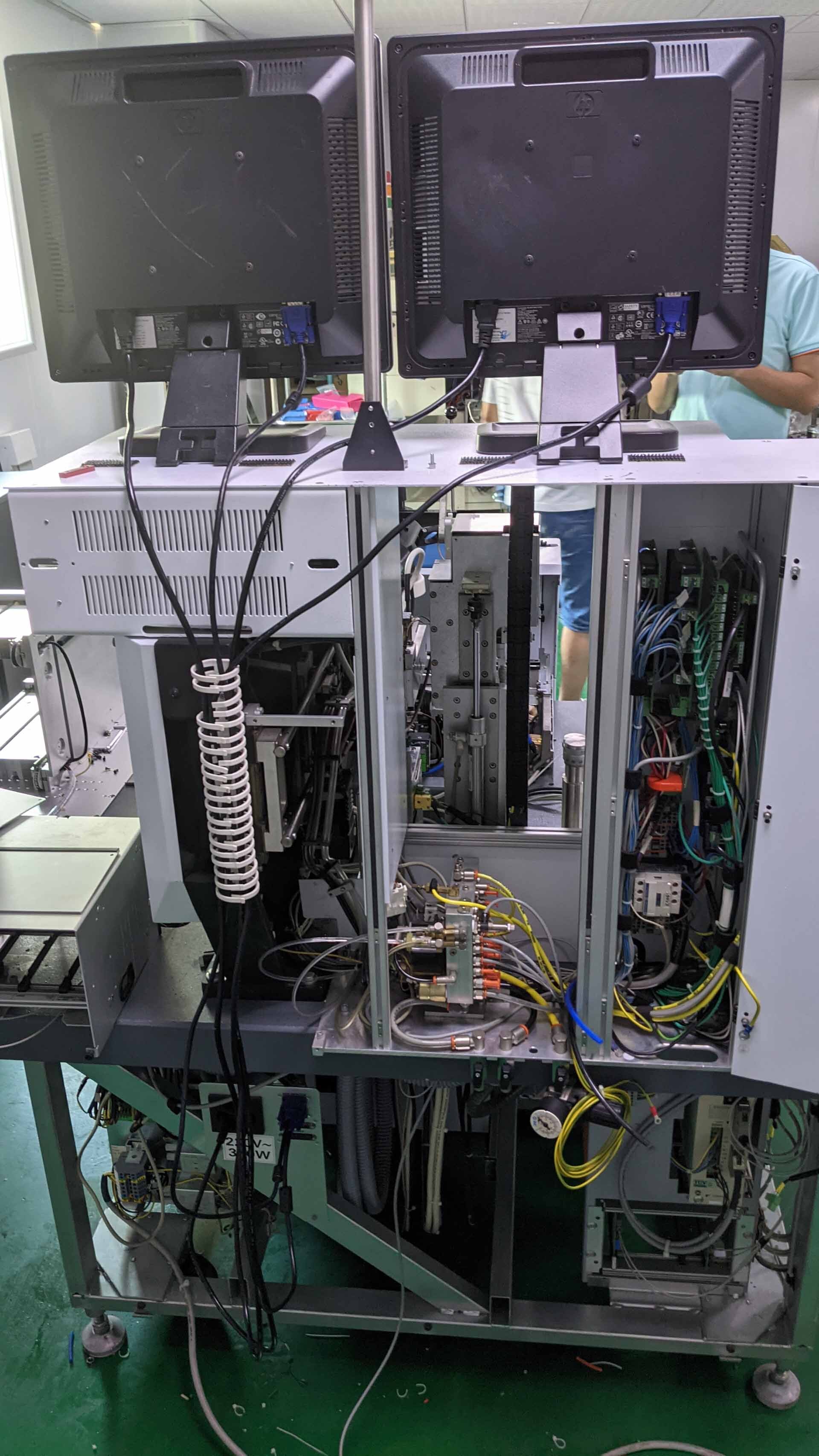

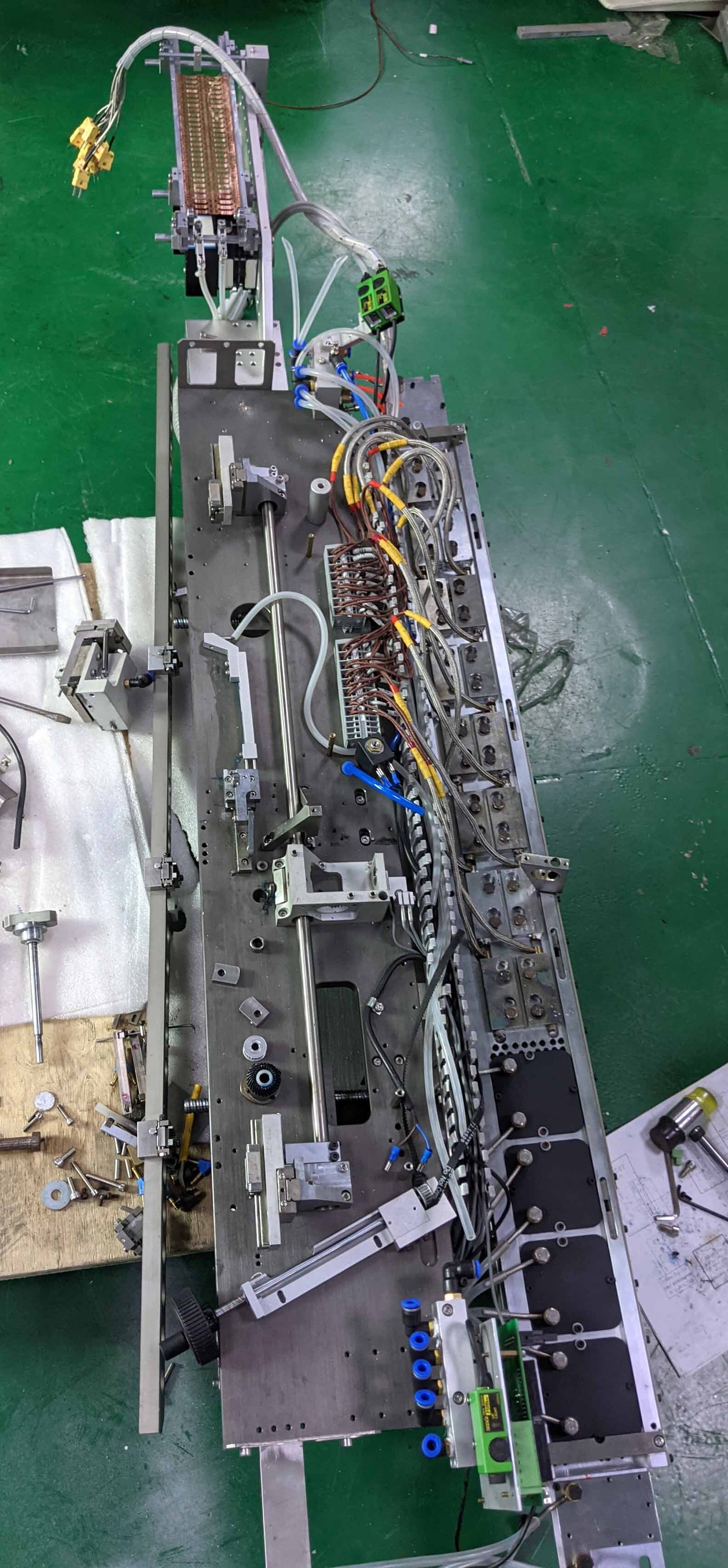

Used ESEC 2007 FS plus #9394055 for sale

URL successfully copied!

Tap to zoom

ID: 9394055

Vintage: 2005

Die bonder

Missing parts:

Covering

Microscope and plate

2005 vintage.

ESEC 2007 FS plus is a die attacher designed for mounting and soldering fine-pitch integrated circuits (ICS). The device offers efficient process control and improved die-attach accuracy with advanced features, such as dual cameras, reject sorting and mapping, and X-Y stationing. The two cameras on 2007 FS plus are used for positioning, inspection, and identification of ICS. The bottom camera works in parallel with the top camera, scanning images on the bottom side of each chip to determine chip size and type and to create inspection and positioning patterns. The bottom camera also has a die-diameter checker feature that can easily image dies from 0.3mm up to 2mm. On the top of the device is a high-resolution vision equipment for inspecting and pre-aligning each die to the board prior to attaching. This inspection system has both an LB (light balance) mode for inspecting bright objects and a white balance mode for inspecting dark objects. The unit supports brief inspection time and maintenance. ESEC 2007 FS plus also features a reject sorting machine. This tool is used to sort out any failed or misaligned dies between the active soldering process. This feature ensures that no bad components are soldered on the board, thus reducing the risk of board failure. The X-Y stationing feature on 2007 FS plus allows for quick customization of the production line. In this mode, different types of components can be attached and soldered simultaneously. The stationing features enable manufacturers to select a specific template that best suits their production line and the size and types of the chips. Finally, the integrated ovens used in ESEC 2007 FS plus provides quick and efficient soldering of ICs. In summary, ESEC die attacher 2007 FS plus is a high-performance machine designed to meet the needs of today's chip assembly and soldering processes. Its features, such as dual camera, inspection, reject sorting, X-Y stationing, and integrated ovens, not only increase productivity but also improve die-attach accuracy. The device can handle even the most advanced and complicated soldering needs of modern production lines.

There are no reviews yet