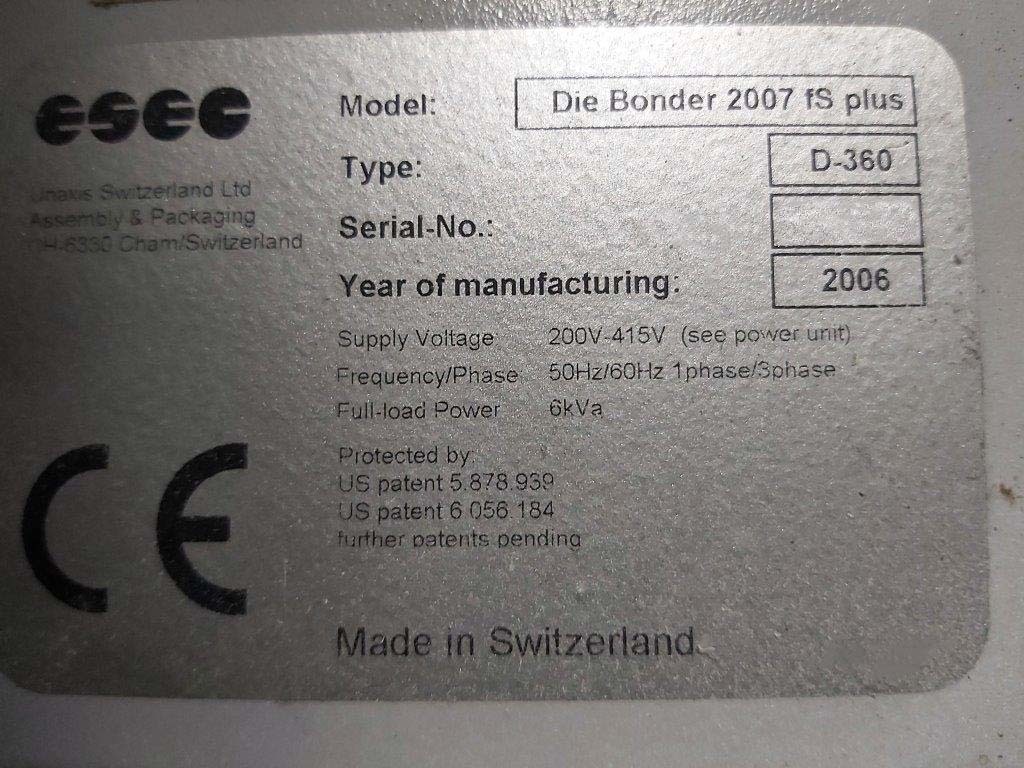

Used ESEC 2007 FS plus #9394237 for sale

URL successfully copied!

Tap to zoom

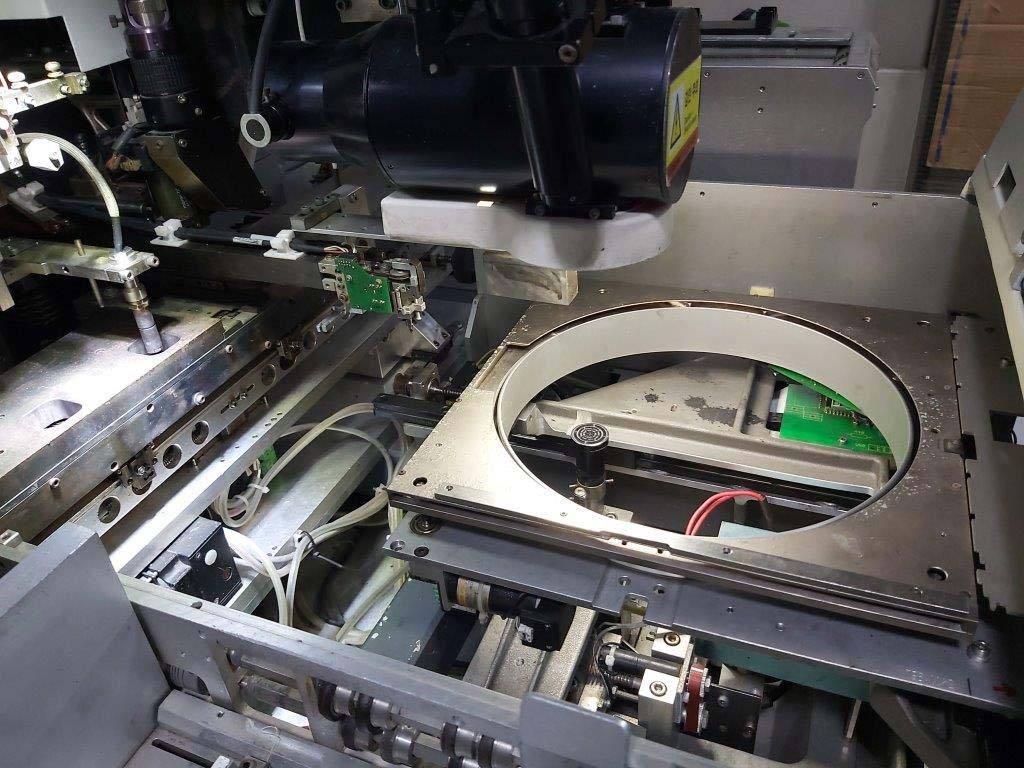

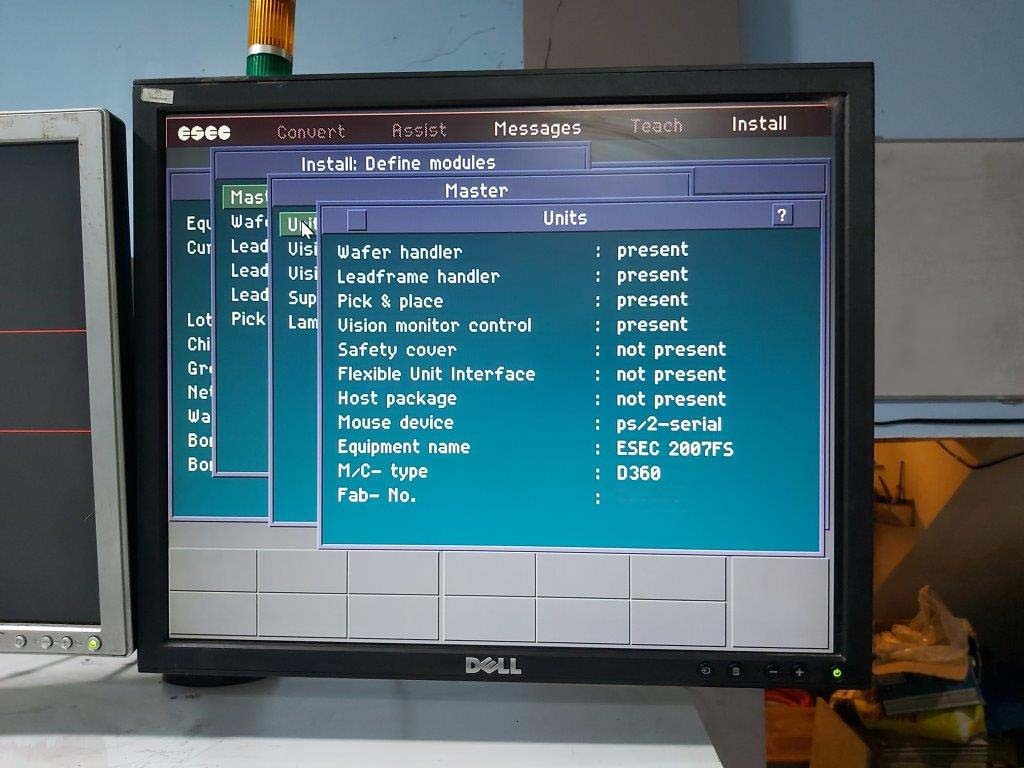

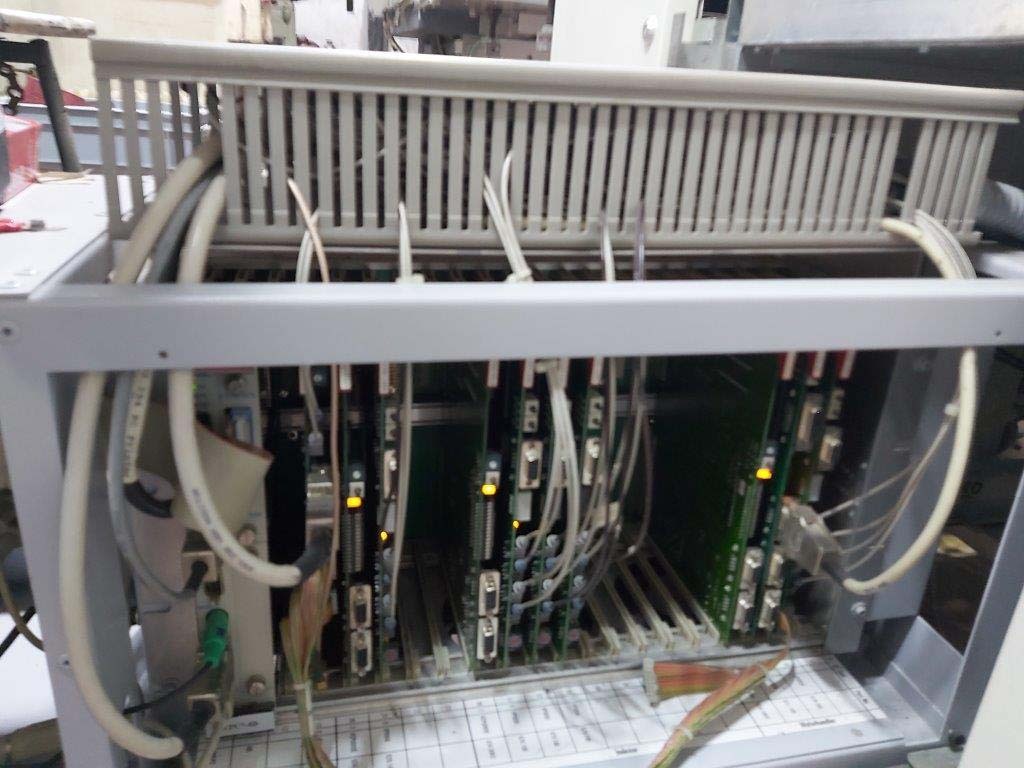

ESEC 2007 FS plus is an automated die attacher designed for high-volume die attachment and wire bonding in the semiconductor industry. The equipment is equipped with a patented heat-resistant tooling system, which allows for high precision handling of delicate components. 2007 FS plus is capable of high speed die attach and wire bonding at up to 0.4 seconds per bond head cycle and 20-50ms per die attach process. The unit utilizes a controlled gas flow of either nitrogen or air, which is delivered at the nick point between the die and the package. A precision critical heat-bucket serves as a mini-oven and provides a highly effective, evenly controlled melting of the die across the attachment surface. This tool ensures the highest level of reliability even at higher process temperatures. The machine also features an integrated high-resolution vision tool, which provides extreme accuracy and repeatability throughout production. This allows for an extremely accurate placement of each die onto the package, ensuring that there is no risk of misalignment or poor adhesion. The asset is also equipped with a proprietary statistical process control (SPC) module that monitors and precisely controls all parameters throughout the entire die attach process. This software module allows for transparent process monitoring and can quickly alert operators to any potential defects or irregularities in the model. ESEC 2007 FS plus is designed with an open architecture that accommodates the needs of different production processes and allows the equipment to be used as a standalone unit or integrated into an existing production line. The system is also equipped with a protective housing that provides a secure environment for all moving parts, ensuring robust operations in a robust and cost-effective manner. Overall, 2007 FS plus is an advanced die attacher that provides the highest level of reliability and accuracy while ensuring safe and efficient production. The unit features a robust design, integrated vision machine, and precision critical tooling that ensures the best results of a wide variety of die attach and wire bonding processes. This tool is ideal for advanced semiconductor operations that require the highest level of accuracy and repeatability from their production line.

There are no reviews yet