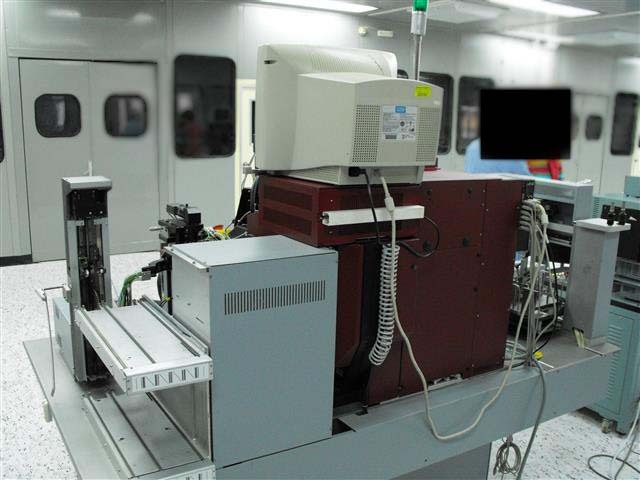

Used ESEC 2007 #9099964 for sale

URL successfully copied!

Tap to zoom

ESEC 2007 Die Attacher is a high-speed machine designed for the automated attachment of flat die onto substrates. It is an easy-to-use and reliable solution for broad panel installing applications. This machine is a reliable and economical way to perform die attachment in production environments. Using a die attachment robot like 2007 increases operating efficiency and throughput and reduces labor costs when mounting dies to material. This machine performs this intricate task with precision and speed. ESEC 2007 is capable of attaching dies with widths ranging from 0.3 mm to 110mm and lengths ranging from 0.4 mm to 130 mm. It is also compatible with a wide range of substrates including metal, plastic and paper. The machine uses vacuum equipment to position and hold the dies onto the substrate. The vacuum system is equipped with an open loop control unit for providing clear image processing assurance. It is also equipped with special agents to help in preventing static electricity. These agents help maintain the integrity of the dies during production. 2007 also features an optically isolated pressure machine. This allows for pressure control and an even pressure distribution across the die. This, in turn, helps to create accurate die positioning and die alignment. The optically isolated pressure tool also helps reduce die slippage and improve the overall accuracy of the feature assembly process. ESEC 2007 is equipped with an automatic laser vision asset for precise positioning of die. This provides a quick and easy way to detect any misaligned die for an improved finish. The machine also features a simple and intuitive graphical user interface for monitoring and controlling the performance of the die attaching process. 2007 Die Attacher is a reliable and economical solution for die attaching needs. It features a reliable and accurate optically isolated pressure model, a robust laser vision equipment, and an intuitive graphical user interface for monitoring and controlling the process. This machine is ideal for both large and small panel mounting applications.

There are no reviews yet