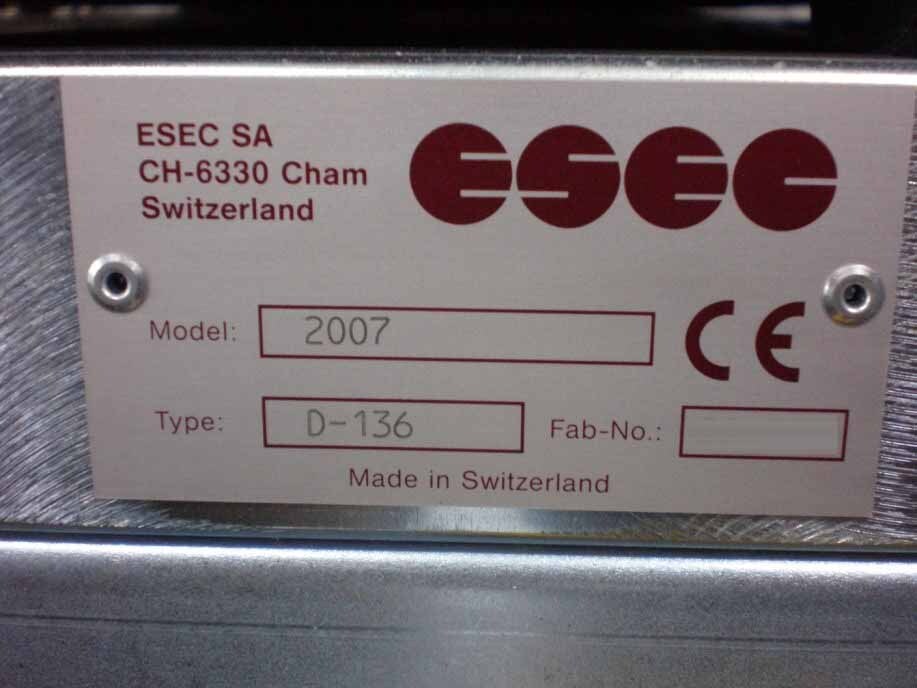

Used ESEC 2007 #9379161 for sale

URL successfully copied!

Tap to zoom

ID: 9379161

Die bonders

Actual dry run

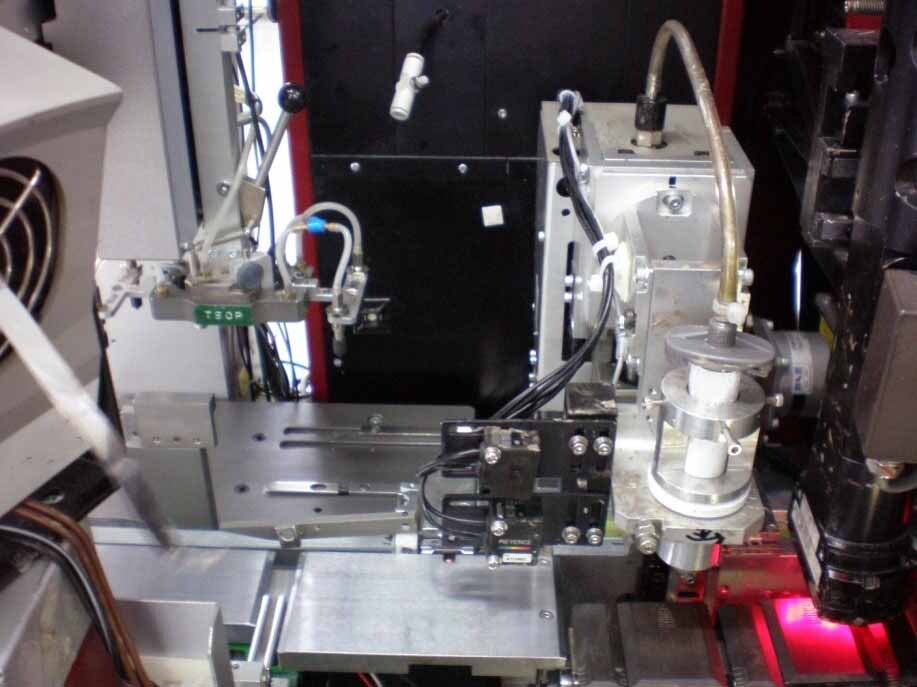

Machine body

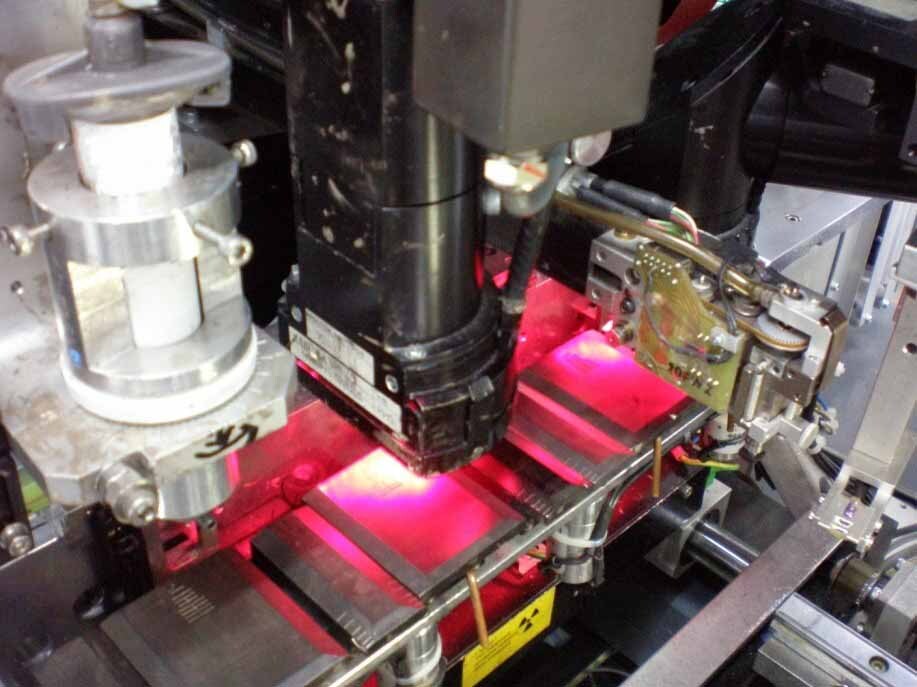

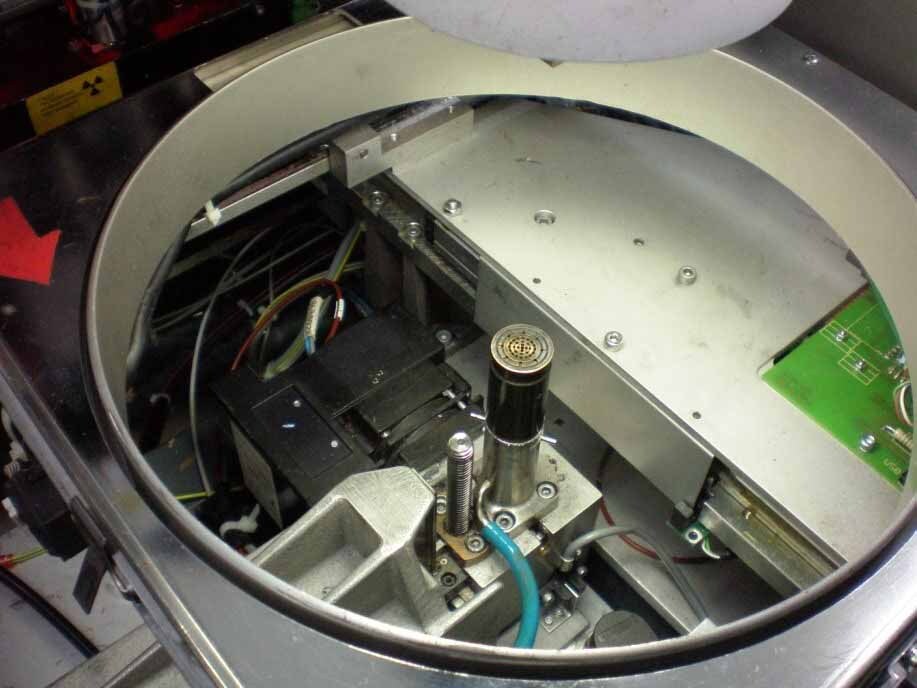

Bond head

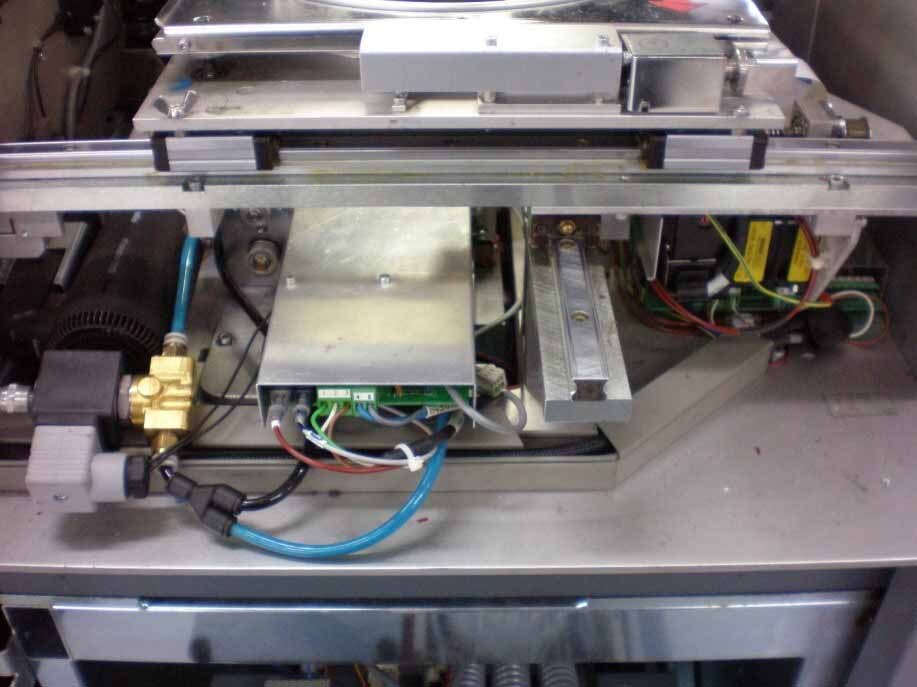

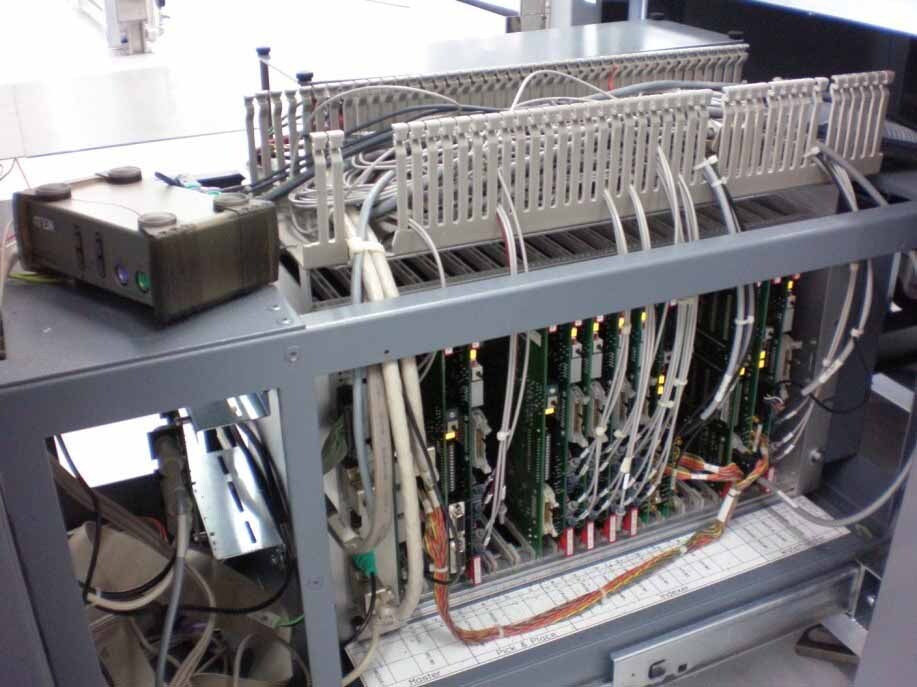

PCB Compartment

Input and output module

Crate:

Electrical cables

Tubling

With wafer loader and un-loaded

Chuck ring table, 8"

Inkjet dispensing.

ESEC 2007 is a die attacher designed for both high-speed production and high-accuracy die attaching. This automated die-bonding equipment is a joint venture between ESEC and an OEM. It can handle both vertical and horizontal die patterns and is capable of 24,000 die placements per hour. The system consists of different parts, each performing a unique task. The pick & place head is responsible for picking and placing the die accurately in its surface-mount pad. Its high-speed operation and precision unit allow for accurate placement with minimal misalignment. This unit is controlled by the Ethernet programmable Logic Controllers (PLC) which controls the entire die bonding process. The precise control of the PLC ensures that the proper amount of die bond adhesive is placed each time the dies are placed. 2007 also features a camera-assisted tooling and part ID unit that helps in achieving accurate placement of components. An identification mark is programmed into the die, which is read by the camera before the bonding operation. This machine performs an image analysis and instructs the machine to bond the die accurately. The die-bonding process is controlled by the Hot Bar Bonding Tool, which uses a heated iron bar to adhere the die to the substrate. The heated bar applies a layer of bond adhesive that shrinks and forms a bond between the die and the substrate. This asset ensures a solid and long lasting bond between the two components. ESEC 2007 utilizes a temperature control model to ensure a consistent bonding temperature. The equipment is also equipped with an automated vision system that tracks the bonding process and checks for any anomalies. This unit prevents misalignment and ensures that each die is securely fixed in its position. By using 2007, manufacturers can optimize the output of their production with a low-cost solution that is accurate, efficient, and reliable. The die-bonding machine offers accuracy, quality, and repeatability in an automated and cost-effective manner.

There are no reviews yet