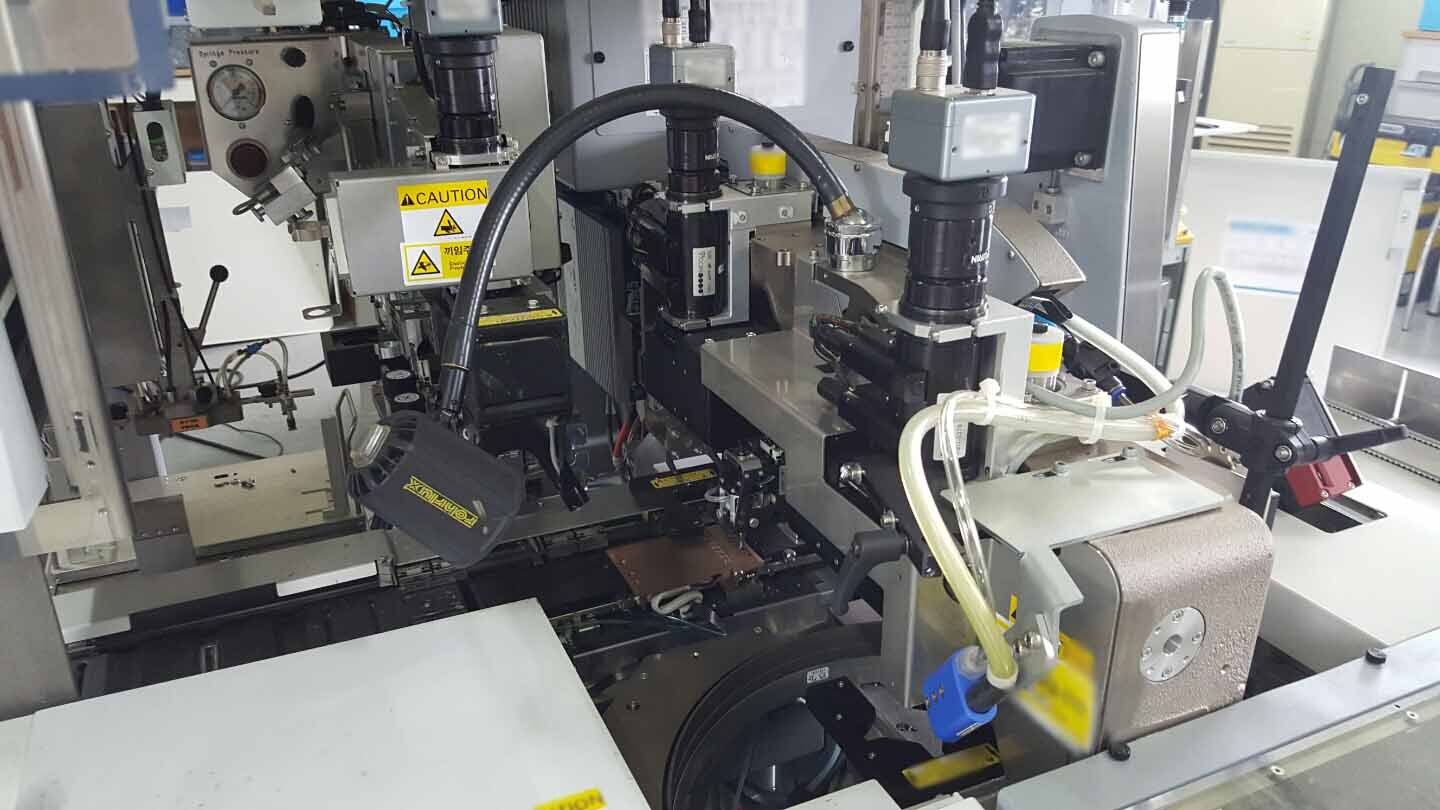

Used ESEC 2008 HS3 Plus #9147294 for sale

URL successfully copied!

Tap to zoom

ID: 9147294

Wafer Size: 12"

Vintage: 2007

Die bonders, 12"

SOT 223 Chip size space: 2.90mm ~ 3.10mm

Stack loader

Magazine to magazine

Bond time: 0 - 32 sec

Bond force: 0.5 N - 50 N

Bond accuracy: 25 um @ 3 sigma

Pad down set: 0 - 3 mm / 0 - 120 mil

Max. Pitch: 80 mm / 3.1"

Multichip:

Max. 3000 die per pitch

Max. 12000 die per lead frame

X Range: Max. 80 mm / 3.15"

Y-Bond range: Max. 66 mm / 2.6" (Leadframe width 90 mm / 3.54")

Die size: 10 mil (0.25 mm) - 1" (25.4 mm)

Die rotation angle: 270°

Magazines length: 120 - 270 mm / 4.72 - 10.23"

Magazines width: 12 - 90 mm / 0.47 - 3.54"

Magazines height: 60 - 160 mm / 2.36 - 6.3"

Wafer handler move method: 8" all & 12" half move

Compressed air: 4 - 6 bar / 68 - 90 psi

OS: Windows 2000

Electrical:

AC 110V, 220V + 10% -15%

50 - 60 Hz

2007 vintage.

ESEC 2008 HS3 Plus die attacher is an advanced tool for semiconductor and electronics manufacturers looking for precise die and component post-dicing and uniform die placement. The HS3 Plus equipment offers a wide range of placement speeds and accuracy to accommodate a variety of applications and can handle parts in various shapes and sizes. The HS3 Plus can place up to 4800 chips per hour, with a placement accuracy of up to 2 μm, making it suitable for placing small, delicate parts and components. The HS3 Plus is equipped with a powerful vision system for precise placement accuracy with no manual adjustments. The vision unit features an 8x lens that can recognize features as small as 0.1 mm, ensuring that each die is placed in the exact location. Additionally, the HS3 Plus can be equipped with optional integrated cleanroom dust pods, which help to reduce the amount of dust entering the product. In addition, the HS3 Plus features a modular design, allowing for easy customization to meet a variety of needs. The machine can be adapted to special needs such as post-dicing cavities or connector holes through the use of shape-recognition software or advanced sensor technology. The HS3 Plus also offers a wide array of custom programming options to further strengthen the quality and accuracy of placement. The HS3 Plus die attacher is a reliable and powerful solution for semiconductor and electronics manufacturers looking for precise placement and post-dicing accuracy. It offers a range of speeds and accuracy to handle parts of any size, and its powerful vision tool offers industry-leading placement accuracy and reliability. Additionally, its customizable programming options and modular design ensures that it can meet individual user needs.

There are no reviews yet